Features

Business intelligence

Codes and standards

Energy efficiency

Event reports

Innovations

Webinars

Top Glass Online: A day of information-rich sessions and much more

July 22, 2020 By Sukanya Ray Ghosh

There is an old and well-known proverb, “Necessity is the mother of invention.” All the innovations and inventions we see around us every day show us how true this is. The greatest examples can be seen in the current times with people constantly adapting to the pandemic to push ahead with what they want to do despite the countless restrictions. Online events are gaining momentum in all industries. Why not the architectural glass industry as well?

The popular industry event Top Glass took place online on July 7, after the live event was initially postponed to September and then cancelled altogether for 2020.

Looking forward to the interesting line-up of speakers and presentations, attendees joined in through the GoToWebinar app at 10 am. And it was an information-packed day indeed.

A young group of experts

The day kicked off with a panel discussion with some young bright leaders of Canada’s architectural glazing industry – Nathalie Thibault of FGIA; Mike Bruno from Alumitex Window and Doors; Andrew Dolphin of BV Glazing and Peter Dushenski of GlasCurtain.

A panel of young leaders discussed pressing issues of the industry.

The conversation started with the impact of the pandemic as witnessed by the panellists. Thibault noted that many companies, especially manufacturers, were not organized for remote workers. This made the transition more challenging for them. FGIA also conducted a survey during this period to find out what kind of training programs its members are most interested in. Bruno and Dolphin noted that proper safety protocols and use of PPE extensively have become the new norm. Asking questions about people’s health is necessary. Cleanliness is at the top of everyone’s minds. Dushenski suggested that commercial real estate would spread out in the future with people not being comfortable with high rise offices.

Talking about energy standards, Dolphin noted that a major shift for the industry would be to move from double silver units to triples. Chinese imports and foreign competition versus local was the next point of discussion. The panellists agreed that it was necessary to protect the Canadian members of the industry. Tariffs should be extended to glass. There is a potential risk of sanctions for buying from China. Therefore, it is better to put contingencies in quoting model as per the risk as well as keeping some reserve if it is necessary to switch to local. When it comes to curtainwall systems, Dushenski noted that there was more competition from European systems compared to Chinese ones.

Looking into what would change over the next decade, the panellists believe energy codes, body carbon and domestic supply chains would evolve. Test methods and protocols would employ stricter standards to ensure more durable products. This in turn would impact cost. Lack of skilled workforce in all aspects of manufacturing would also influence production numbers. Dolphin noted that automation was the future for increased productivity.

Touring a fabrication facility

How do you make an online presentation more interesting? A lot of videos? The next session did just that. Louis Moreau from AGNORA was able to take all attendees through a tour of AGNORA’s fabrication plant while he showed why architects want larger glass and how it is produced. The entire series of pre-recorded videos was able to keep the audience hooked till the end. They were able to see different processes in the plant, including cutting, edgework, lamination, IGU, heat treatment and heat soak testing.

Louis Moreau took attendees on a video tour of a fabrication facility.

The objective of this presentation was to convince attendees to make and install oversized pieces of glass. Moreau explained that oversized glass should be used as it removes barriers between spaces. It offers maximum visibility and communion with surroundings. High ceilings and big buildings need oversized glass cladding. When it comes to building aesthetics, natural light improves behaviour, increases purchases, delivers impressive vistas for residences and creates landmarks in high-profile buildings, according to Moreau. He pointed out that oversized glass can be extremely efficient. While building, each crane movement, each large panel can lay more area, resulting in fewer parts of the “puzzle”. There is less caulking and less hardware. For the building, glass is the only cladding material that brings energy into it. It is possible to control that energy with proper coatings and insulation.

Moreau noted that the presence of nickel sulphide particles can shatter the glass. Heat soak testing eliminates that. After going through the process, the glass shatters and has to be remade. But it ensures that all nickel sulphide is eliminated. This is good insurance.

When using oversized glass, thicker glass needs to be used. In North America, the ASTM E1300 standard allows architects to get proper thickness for the load. Large glass also means more effort and requires heavier structures. Deflection needs to be controlled. It is also important to know the limits and sizes. It’s not just the glass. Laminates and IGUs have to be taken into consideration. Laminates must match the size of the glass.

According to Moreau, certain design considerations are overlooked. The best in impact safety is annealed laminate. The glass breaks in large portions allowing the form to be maintained by the laminate. Heat-strengthened laminate comes next as it provides adequate protection in most applications and resists most thermal stresses. The glass breaks in large chunks.

Ending the presentation with the logistics of handling, Moreau noted that it is important to think ahead when dealing with oversized glass. Safety comes first. Work with fabricator on packaging, labelling and sequencing. Buy or rent the best equipment.

Fired up over fire-rated glass and glazing systems

The third session of the day focussed on what glazing contractors and architects need to know about fire-rated glass and glazed systems. Presented by Fred Fulton of F1 Glazing Solutions, started the presentation with the basics and key attributes of glass. He noted that everyone wants the best visual clarity; impact safety glass (tempered, laminated and filmed) is necessary; and tempered glass is the best option for superior durability. He noted that when we talk about fire-rated glass, these are some of the big questions that need to be asked: Does it have to be rated? What is the rating? Interior or exterior? Is impact-safety required? What type of glass? What type of framing? Fire-protective (basis) versus fire-resistive (the higher category)?

There are two classifications of fire-rated frames and doors. Fire-resistive system acts as a barrier to radiant heat. The rating of fire separation is different from rating of closure. Don’t confuse wall ratings with glass and frame ratings, advises Fulton.

Fulton noted that there are area restrictions to be considered. Codes may dictate the type of product for given location or condition.

He also pointed out that in a fire-wall, the aggregate width of all frames and doors cannot exceed 25 percent of the width of the fire-wall. To exceed the 25 percent rule, you have to go to a fire-resistive S101 system. Fire-resistive curtainwalls on the other hand have no limit on overall width, height and area. Spandrel is rated panels or frit. The glass is always intumescent.

Fulton also shared the following rules.

- Fire-rated products must be furnished and installed “ as per OBC” or “as tested and (ULC) listed”.

- Never mix and match rated and non-rated products. Fire-rated frames must terminate into fire-rated construction – cannot terminate into non-rated windows, break-shapes or thin air.

- Install in conformance with impact-safety and guard-load.

- Do not make up your glass make-up

The presentation ended with safety glazing standards for the different categories of fire-rated glass – Georgian polished wire, ceramic fire-rated glass and intumescent fire-rated glass.

How to achieve energy code targets?

Louis Fortin and Claudio Bardetti from UL were the last presenters of the day. Their session focussed on the current state of baseline energy codes for commercial façade design, where they are heading and the strategies to achieve them.

Bardetti took the attendees through the evolution of baseline energy codes starting at the energy crisis in the 1970s, moving on to the Paris Accord and then to the pan-Canadian framework. The pan-Canadian objectives include making more energy-efficient buildings; retrofitting existing buildings; improving energy efficiency for appliances and equipment; and supporting building codes and energy-efficient housing in Indigenous communities. Bardetti pointed out that often when a new energy code comes out, it does not have any force unless the provinces adopt them. Also, to be noted is that the energy codes are baseline markers, the strict minimum that needs to be done. Many developers actually request to go above and beyond the baseline energy codes. Provinces also often make amendments to the national energy codes. Key points that will influence energy codes were also shared during the presentation. Touching on code structures and paths to conformity, Bardetti noted that there are three options – the prescriptive option, the trade-off option and the performance option.

Taking the baton from Bardetti, Fortin went on to discuss what is achievable with actual fenestration systems, especially with present-day technology. He discussed the code evolution in terms of fenestration u values. Technical information was shared regarding curtainwall optimization; European system wood mullion; European system aluminum mullion; Canadian system fibreglass mullion and the latest glass innovations. Concluding the session with tools that could help achieve the targets, Bardetti noted that innovative software offered several advantages in this regard.

Interactive and ongoing

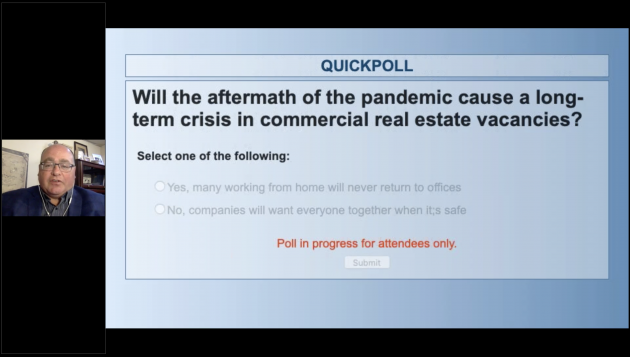

Quick audience polls kept the event interactive throughout.

To keep the interactivity with the audience going throughout the day, each session was followed by some Q and A time. Attendees sent in their questions during each presentation. The speakers answered as many of them as time permitted. Attendees were encouraged to get in touch with the speakers afterwards in case their questions were not answered or they had some new ones. Some quick audience polls were also interspersed in-between the sessions to keep attendees engaged.

Online platforms offer a unique advantage. While the actual event is over, Top Glass online remains an ongoing event full of all the valuable information that was shared. Those who did not get the opportunity to participate on July 7 can simply visit the event page, register and access all the knowledge-heavy sessions at their leisure.

Print this page

Leave a Reply