Features

Business intelligence

Contracting

The vulnerability of windows

Project evaluates the effectiveness of window-wall...

May 9, 2008 By *

Project evaluates the effectiveness of window-wall interface in managing rainwater.

One of the most vulnerable points in the building assembly with respect to water tightness is the window opening. Given the many different types of windows and related components, there are a number of different approaches to their installation. But which methods ensure water tightness at this critical location? And which installation measures are most likely to ensure their optimal long-term performance?

|

| Mounting flanged windows on furring strips or using shims behind the flange provide the openings necessary for proper drainage. |

The NRC Institute for Research in Construction (NRC-IRC) and the Canada Mortgage and Housing Corporation (CMHC) are leading a study in a collaborative research project to evaluate the effectiveness of various window-wall construction details in managing rainwater over the life of the wall assembly.

Researchers have assessed the ability of such details to mitigate rainwater penetration into the wall assembly by subjecting pairs of similar sized windows with varied interface details to simulated wind-driven rain. Each pair was tested under a range of climate loads likely to occur over a 30 year period and under the loads used in standard water penetration tests.

Based on expert advice on window installation practice in Canada, four different pairs of window-wall interface details were selected for examination. These included combinations of both boxed and flanged vinyl windows installed with hardboard siding in either a rainscreen or non-rainscreen design. Variations in the installation details included:

1. Drip-cap flashing.

2. Self-adhering membrane flashing to seal joints between components.

3. Redundant sealant joints to retard water entry.

4. Shims on which to install windows.

A summary of selected results show the vulnerability of windows to water entry is in part related to the complexity of the installation details and process, and to the competing needs of ensuring proper lapping of the different components during the installation. The choice of components and the sequence in which they are installed both play an important role in determining the vulnerability of different window-wall interfaces in managing rainwater.

|

| Deterioration is most pronounced around the lower portion of the window where water has infiltrated behind the sheathing membrane at the window opening, leading to both staining from mould growth and wood rot of the sheathing board. |

Key observations

The rough opening is most likely to get wet over its service life. Therefore, it should be designed to promote drainage and be properly flashed to ensure water tightness at the sill. Specifically, the rough opening should:

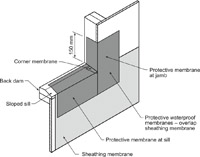

- Incorporate a sloped sill, a back dam, the use of a waterproof component such as a metal or plastic pan or a self-adhering waterproofing membrane on the sill and at least 150mm up the side of the jambs.

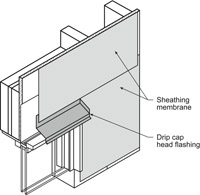

- It should be carefully integrated with other elements at the window-wall interface. For example, there should be proper sequencing and shingle lapping with the sheathing membrane and protective components along the height of the jambs and at the window head.

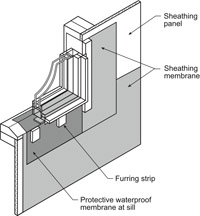

Drainage at the window sill should be facilitated by avoiding measures that retard or prevent drainage of incidental water at the sill. For example, when using a flanged window, the flange should be placed on shims or furring strips to provide a gap between the flange and the window opening through which water may drain.

Results from this ongoing collaborative study will be incorporated into a best practice guide for window installation for both low-rise wood frame construction and high-rise residential buildings to be published by CMHC.

To participate as a sponsor or partner, or to obtain more information about this work visit: http://irc.nrc-cnrc.gc.ca/bes/hmpe/rainwater_e.htmlSpecific questions can be directed to Dr. Michael Lacasse at (613) 993-9715, fax (613) 954-5984, or e-mail: michael.lacasse@nrc-cnrc.gc.ca

Evaluating the effectiveness

The objectives of this laboratory project evaluated specific window-wall interface construction details to determine how effectively they manage rainwater intrusion into a wall assembly.

Inadequate detailing and installation of windows are causing a significant number of building envelopes to fail prematurely. To reduce the number of failures, new construction details have been developed to better manage water intrusion at the window-wall interface. The project evaluates the effectiveness of these details.

The study began by developing a procedure to assess how rainwater penetration occurs in a wall assembly. Then, using a dynamic wall testing facility, researchers assessed the water management capabilities of specific construction details for a select combination of window types and wall cladding systems, such as vinyl and hardboard, installed according to both standard methods and variations of best practice. The facility simulates wind-driven rain conditions on wall specimens 2.4 by 2.4 metres in size.

The results of this collaborative study will verify the effectiveness of the window-wall interface details and the information will be used by Canada Mortgage and Housing Corporation to develop a best practice guide for window installation in both low-rise wood frame construction and high-rise residential buildings. Detailed results on the performance of each wall assembly tested will also be available. -end-

| Figure 1. Window opening showing components and key features that promote drainage and protect sill. | |

|

|

| Protective membrane and proper sequencing of overlapping components at window sill. | Lapping of sheathing membrane and protective membrane at window sill. |

|

Author’s note: The diagrams only illustrate certain key components and their function in the window-wall interface assembly. Certain details have been omitted to render clarity to the diagrams. They are meant to provide guidance, but are incomplete and should not be used for design purposes. A complete set of design details will be provided in the final report. |

| Drip-cap flashing and overlapping of components at window head. | |

Article reproduced, with slight revisions, from Construction Innovation, Volume 11, Number 2, June 2006, with the permission of the Institute for Research in Construction, National Research Council. Photos and figures courtesy of CMHC.

Print this page