Features

Business intelligence

Contracting

Agnora to the rescue

Jumbo glass production survives in Collingwood under new ownership.

June 25, 2012 By Patrick Flannery

Some say value-added manufacturing cannot work in Canada.

Some say value-added manufacturing cannot work in Canada. Our costs are too high, our domestic market too small and spread out. We are forever consigned to the role of hewer of wood and drawer of water. Others point to our educated population, sophisticated infrastructure, easy availability of capital and proximity to the biggest market in the world and wonder why we are not already on par with the likes of Japan and Germany when it comes to making and exporting advanced finished goods. The decline and fall of Barber Glass in late 2010 seemed to make the case for the naysayers. When John Barber risked $24 million to build the largest capacity architectural glass processing facility in North America, maybe he reached too high. From the failure of Avro to the recent declines of Nortel and RIM, maybe Barber was just another sad milestone on our nation’s meandering path through the wilderness of manufacturing obscurity.

|

|

| All the machinery at Agnora is highly automated and oversized. This Bystronic laminating line features robotic alignment of the layers and can process sheets up to 130 by 275 inches.

|

Not if Richard Wilson has anything to say about it. A Toronto-based developer and native of Collingwood, Ont., Wilson stepped up at the last minute on May 6, 2011, to forge a deal with Gord Tozer of Caledon, Ont., to save the plant from auction and relaunch its operation as a fully functioning architectural glass provider under the name Agnora. In doing so, he saved about half the jobs at the Barber operation and kept the dream of world-class advanced glass production alive in Ontario and Canada.

Wilson is 50 years old and has two teenage boys. His wife, Laura, works with him at the plant. He grew up in Collingwood, the son of Rev. Douglas Wilson, a Presbyterian minister. He has been entrepreneurial and involved in construction since he was 14. He has kept a finger on the Collingwood business scene over the years, opening a bungee jumping attraction at Wasaga Beach and a local sporting goods store. But his main business was Wilson Project Management, a construction contracting and project management company specializing in custom builds and renovations for very high-end residences and commercial properties. Many of Wilson’s projects have had avant gard architectural designs demanding large and/or unusual window and window wall treatments. Thus his involvement with Barber and the specialty glass panels it was able to provide. Wilson was a major customer of Barber prior to its collapse.

| Location: Collingwood Product: Jumbo architectural flat glass, laminated glass and insulating glass units. Ownership: Richard Wilson and Gordon Tozer Employees: 25 Plant size: 280,000 square feet Capacity: 130 by 240 inches Wilson and Tozer bought the Collingwood assets of bankrupt Barber Glass hours before they went to auction. The new company, Agnora, boasts some of the largest architectural glass processing equipment in North America. |

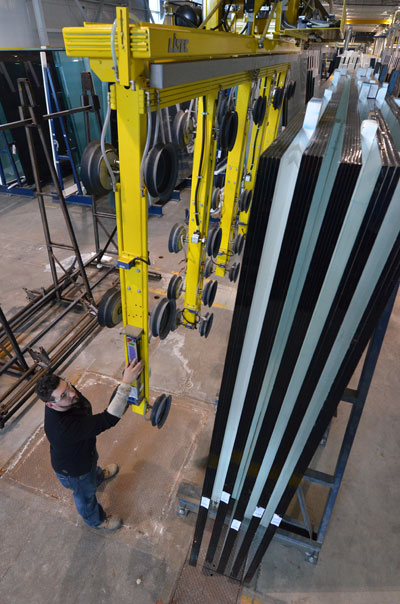

Agnora operates in 225,000 square feet of the 280,000-square-foot plant that Barber built in 2008. It is employing about 25 presently, though Wilson confidently predicts this number will rise. Agnora can automatically cut and seam sheets of flat glass up to 130 by 240 inches on its Lisec cutting and seaming lines. It can temper 130- by 280-inch panels in its Glaston tempering oven. Twin Intermac CNC routers can machine panels up to 130 by 240 inches each. The Adelio Lattuada single edger can process sheets up to 130 by 300 by two inches, with an even bigger one on the way. The Bystronic laminating line can automatically laminate sheets up to 130 by 240 inches, or manually laminate sheets up to 275 inches long. The Lisec IG line takes sheets of flat glass and creates insulated glass units up to 130 by 240 inches across with minimal handling by the operator. The line can apply the adhesive and seal around the outside of an eight-foot-square IG unit in 12 seconds. Agnora’s enormous ASC autoclave can bake laminated glass sheets up to 134 by 300 inches. The Giardina paint line can paint an 86- by 240-inch area. All of the equipment is less than four years old. Wilson gives Barber full credit for building one of the most advanced and largest-capacity glass production facilities in the world. As he tours the shop he says over and over, “I’m the luckiest guy in the world.”

Wilson’s purchase of the Barber plant was the stuff of high drama. Ever since Barber announced it was going into receivership, Collingwood’s economic development office had been in overdrive trying to find a buyer who would keep the glass production operations in town. When they contacted Wilson initially, he was only interested in a minor partnership because it looked like control of the operation would be diffused over many stakeholders and he is, by his own admission, “not a big partnership guy.” The Collingwood team managed to get a group of buyers in place, but one of the major investors dropped out literally the weekend before the sale was to take place. With the auction date looming, Barber’s operations manager, Jeff Wilkins, urged Wilson to step in. Finally, the day before the auction, Wilson called Gord Tozer, one of the major investors from the original group, as he was flying to Calgary. “I said, ‘Look, I think this is a good business,” Wilson remembers. “I have a strong background in the industry and I have already got pre-sold stuff to buy. I want to make an offer. Will you go partners with me?’ And I didn’t even know the guy. I had met Gord twice but for about half an hour each time. But he is the type of guy who will do things on a handshake. And not knowing the guy, nothing in writing, he said, ‘Yes,’ so I gave them a million and a half, non-refundable.” Wilson says the partnership works well because Tozer has approached his stake in the company as an investment, while Wilson is more interested in marketing and company-building, leaving operations to his general manager, Wilkins. “I am the sales portion of it, Jeff is operations and Gord is the guy who keeps us grounded with financials,” he explains. “So between the three of us we are a fantastic team.”

This approach may sound rash, but Wilson had his reasons. “I was doing it because it is a good thing for Colling-wood,” he explains. “And it is a good thing for my construction company because I always had problems sourcing good quality glass. I had to go to Europe. So I was being self-serving in a sense because I didn’t want [Barber] to go down because I put a lot of energy into helping develop this as well.” Wilson’s reasons aside, there was a more visceral urge behind his last-minute decision to grab the plant. “I like to win,” Wilson admits.

It is often said of entrepreneurs that where others see risks, they see opportunities. Wilson embodies this philosophy perfectly. “I was asked the question just a little while ago, ‘Don’t you see the risk in this?’” he says. “I said no. I don’t see risk, I see just the benefit of doing things. Things work out. If you work hard and there is a good business plan it works out. There is no risk. There is only risk if you are not willing to put the effort into it.”

|

|

| Agnora’s insulating glass line is the largest in North America, capable of aligning, inserting spacers and sealing panels up to 130 by 240 inches. The line also has the capability to produce offset units, including four-sided offsets.

|

|

|

Agnora’s business strategy is to be a high-end, automated, custom glass provider. Most of the equipment in the shop incorporates material handling cranes, vacuum lifters and robotic functions. In most cases, this is necessary simply because of the huge panels the equipment is designed to process. However, this level of automation leads most industry people to assume Agnora’s best strategy is to leverage its investment in automation into a low-cost, high-volume range of commodity products. Wilson will have none of it. He points to the fact that other large flat glass producers such as Guardian and Pilkington (Pilkington operates an automotive glass plant just on the other side of Collingwood) passed on buying the plant despite its bargain price. Some even expressed regret that they had to walk away from such an impressive facility. But their corporate strategy demands a certain market within easy geographical reach of an investment of that size, and central southern Ontario simply does not deliver. The big suppliers’ business model depends on shipping a certain volume of product, and beyond a certain range the shipping costs eat too far into the margin. So Wilson understands he needs to take a different approach. He needs to use his automation and equipment capacity to take jobs no one else can do. He has to be willing to operate and deliver anywhere in North America, and to make his service levels so high that his customer will absorb the delivery costs. Wilson describes his target customer this way: “A customer who is installing a piece of glass in New York, who is shutting down a street, has a 200-ton crane in there. He has police, he has everything and he has a $40,000 piece of glass. Well, the $40,000 piece of glass is the cheapest part. So he needs to know that when we supply something to him it is good and we have done all our due diligence and supplied him the best product we can that will meet his standards.”

Wilson and Wilkins feel the high-margin custom strategy will work because large architectural glass is one of the hottest trends in construction in North America right now. “The fastest-growing segment of the industry is the jumbo, no question,” Wilkins says. “Pilkington has said that for the last three years. So for us, little old Agnora, is there $60 or $70 million worth of high-end, high value-added work? Absolutely. Is it growing? It is growing at double-digit rates. So, why not? Let’s focus there.”

Another advantage Wilson and Wilkins see in the custom market is the ability to protect margins against offshore competition. “It is a slippery slope, competing against the Chinese,” Wilkins says. “Is the price going to go up? No, it is not. So which way is the price going to go?” Wilson chimes in, “Why commoditize something like that? We have a company that can do something no one else in North America can.” Wilson says he is even willing to accept short periods of idle time and overstaffing in order to be readily able to meet customer demands. Labour costs constitute a relatively small part of the overhead in his highly automated shop, so he feels little pressure to wring every ounce of productivity out of his staff. “We are not going to chase bad work,” Wilson says. “That is what a lot of companies fall into, especially in a downturn. They chase bad work just to fill the void and to keep their people employed. They just get farther and farther in the hole and they do not realize that they are driving themselves into bankruptcy.” Wilson tells his staff they do not have to worry about such scenarios. “No one gets laid off, no matter what,” he says. “My staff is the least of my worries. My hydro bill every month is much more than all their wages.”

Wilson and Tozer’s rescue of architectural glass manufacturing in Collingwood has attracted national attention and the gratitude of various levels of government. FedDev Ontario, an agency of the federal government, made a $3.71 million grant to Agnora in March to help the company with its planned research and development initiatives. The company is planning to build an R&D lab with dedicated equipment for trying out new processes. Now, Agnora is using its regular production equipment to research new ideas, but this is not optimal because the research project has to wait for time on the production machine. Wilkins is thinking about researching some new performance interlayers to improve their laminated products, and he also plans to test a new soft coat from Saint-Gobain that may become the first-ever jumbo-sized soft-coat product in North America. But if Agnora’s plans are successful, it will achieve an even more important feat: giving support to the optimists about the future of the Canadian glass industry.

Print this page

Leave a Reply