Low-E glass has evolved considerably since its inception spawning new

variations of itself in high performance and reflective glass. After

flattening out in the late 1990s, the rejuvenation of low-E glass in

commercial glazing projects has been evident in several high profile

buildings in both Canada and the US.

Low-E glass has evolved considerably since its inception spawning new variations of itself in high performance and reflective glass. After flattening out in the late 1990s, the rejuvenation of low-E glass in commercial glazing projects has been evident in several high profile buildings in both Canada and the US. The advancements in glass coating technology for both the ‘pyrolytic’ and ‘sputtered’ processes have already produced a wave of ‘easy-clean’ glass products and spectrally selective glass. This new age of glass has prompted new opportunities as architects and designers are taking notice. Glass Canada magazine invited several key companies to discuss the new trends in coated glass products.

|

| The Sysco Building in Cleveland, Ohio, glazed with Pilkington’s Eclipse Advantage Reflective Low-E Glass. Photo Courtesy Of Pilkington Building Products North America. |

Pilkington Building Products North America

Scott Hoover, senior manager for architectural marketing

Pilkington North America is using its patented chemical vapour deposition (CVD) process to make its pyrolytically coated glass products, versus a sputter coated or ‘soft coat’ glass. Unlike soft coat, pyrolytically coated Pilkington glass can be stored indefinitely with absolutely no loss in performance, minimizing inventory loss.

During the manufacturing process, the chemical composition of the coating is applied while the glass is molten, thereby being an integral part of the surface, rather than a coating. In addition to the long shelf life, pyrolytically coated glass can be handled using standard float glass techniques. It also can be readily tempered or heat strengthened, if required, because the durable pyrolytic coating can withstand the required furnace temperatures. Preparation time also is reduced further because no edge deletion is required prior to fabrication, unlike soft coat glass. Both coating processes have made significant product advancements.

Guardian Industries

Tim Singel, director of residential glass products, and Chris Dolan, director of commercial glass products

Guardian uses the magnetron sputtering vacuum deposition (MSVD) ‘sputter’ coating process as well as other proprietary glass coating technologies. Guardian has launched a variety of new coatings in recent years to meet many different customer and market needs. The largest coated glass market is for residential and commercial low-E. In these markets, sputter coated glass has grown to be the major portion of the market with pyrolytic coatings showing little growth and possessing a much smaller share. This is due to the better performance and aesthetic options of sputter coatings and greater availability.

|

| The 360 Condo Building in Toronto, Ontario, uses Pilkington Grey in the large tower, and Arctic Blue, Eclipse Advantage Reflective Low-E glass in the smaller tower. The project fabricator is ProTemp Glass in Concord, Ontario. The glazier is Toro Aluminum, also in Concord. Photo Courtesy Of Pilkington Building Products North America. |

PPG Industries

Rob Struble, manager of marketing and communications, flat glass production

PPG manufactures coated glass products using both the pyrolytic and magnetron sputtering vacuum deposition (MSVD) processes. These products are used for both residential and commercial applications. Pyrolytic technology is used for the manufacture of Sungate 500 low-E glass, while the MSVD platform is employed on Solarban 60, Solarban 70XL and Solarban 80 solar control low-E glasses.

MSVD applied coatings, such as those on the Solarban glasses by PPG, are engineered to block the heat gain in buildings generated by direct solar exposure. By actively blocking the transmission of solar energy, glazings made with these coatings produce dramatically lower cooling costs than is possible with passive low-E products, such as Sungate 500 glass, which is designed to transmit greater amounts of solar energy.

MSVD applied coatings also produce lower ‘U’ values (‘insulating’ values) than glass manufactured with pyrolytic coatings. Curiously, the importance of ‘U’ value seems to be understated in Canada’s energy rating system, which places a greater emphasis on glass shading coefficient. The elevation of the shading coefficient, which measures a glass’ ability to transmit solar energy, over ‘U’ value seems incongruent when one considers that the warming benefits of sunlight are limited to the daylight portion of the day, while glass insulating characteristics conserve heat and energy 24 hours a day.

AFG Glass

Jon Hughes, manager, architectural glass

AFG Glass offers sputter coated (soft coat) and pyrolytic (hard coat) low-emissivity products, manufactured using state-of-the-art coating technologies. AFG’s extensive low-E family is the industry benchmark, representing new levels of product innovation that go far beyond competitive glass products. AFG’s low-E family include spectrally selective solutions that meet exacting customer specifications for energy performance, day lighting, comfort and architectural aesthetics, while providing the inventory and durability to meet the stringent demands in the fabrication processes and the speed to market demanded by today’s construction.

Viracon

Don McCann, manager of architectural design

Viracon is a glass fabricator that produces its own sputter coated glass using the sputter coated process. The company is a fabricator that does not purchase sputter coated glass, but produces its own in-house products.

Currently, it offers more than 36 Solarscreen sputter coatings which can be incorporated into more than 1600 combinations – consideration is made using 1⁄4in (6mm) glass thickness, if using all glass thicknesses it is well over 3000 – of tinted glass, insulating, laminated and silk-screen applications to obtain the desired solar energy performance and aesthetic preference.

|

| See the difference. Pilkington’s OptiView Ant-Reflective Glass on the right compared to the reflectivity of standard clear float glass. Photo Courtesy Of Pilkington Building Products North America. |

By nature, the pyrolytic deposition process and the limited number of metals that can be used in the process restrict the level of solar energy performance that can be achieved. In addition, pyrolytic low-E coatings are not offered in combination with all coloured glass substrates and thickness of glass. These products are generally used where the desire exists to improve energy ‘U’ values and solar performance compared to non-coated glass. However, it does not give the range of offerings that sputter coated products do.

The magnetron sputtering vacuum deposition (MSVD) process, where metals are sputtered on to finished glass in a large vacuum chamber, which are commonly called ‘soft coat’ coatings, allows an expanded list of metals to be used, resulting in improved product ‘U’ values and overall solar performance. In addition, this method offers increased flexibility to apply the coating to a variety of coloured glass substrates, further enhancing solar performance and offering more aesthetic options. For example, if you upgrade a clear uncoated monolithic lite of glass to an insulating unit with a vacuum deposition low-E coating on the #2 surface, you can optimize the solar performance by up to 50 percent. Results are based on the use of Solarscreen 2000 low-E coating by Viracon and a southern climate.

Cardinal IG Company

Bob Spindler, vice-president, technical services

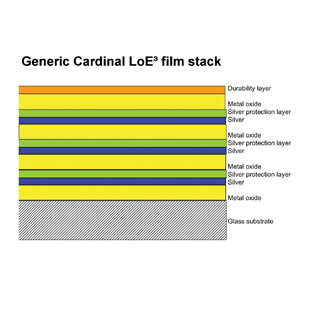

Cardinal uses state-of-the-art sputtered technology for its low-E coatings. Sputtered technology has the ability to produce low-E coatings with very low emissivity, such as, 0.02 to 0.04. This attribute of sputtering technology significantly reduces the centre of glass and overall window ‘U’ factors.

Coatings produced using sputtered technology also significantly reduce the solar heat gain coefficient (SHGC), which also reduces solar gain and air conditioning costs. Pyrolytic low-E

coatings have significantly higher emissivities and SHGC and therefore are not as energy efficient as sputtered low-E coated glasses.

|

| Guardian Industries’ Sputter Coating line in Bascharage, Luxembourg. Guardian has recently launched ClimaGuard SPF, the first coating designed to provide complete protection from damaging UV rays without sacrificing natural daylight. Photo Courtesy Of Guardian Industries. |

Pilkington Building Products North America

Scott Hoover, senior manager for architectural marketing

Both areas have seen technological success such as self-cleaning glass, improved low-E products and anti-reflective coatings.

Guardian Industries

Tim Singel, director of residential glass products, and Chris Dolan, director of commercial glass products

The simple answer is both markets have strong demand for coated glass. Guardian’s residential low-E products continue to be well-received throughout North America, posting significant gains annually. Recognizing the shortcoming of all low-E products when it comes to UV protection, Guardian has also recently launched ClimaGuard SPF, the first coating designed to provide complete protection from damaging UV rays without sacrificing natural daylight.

In commercial markets, Sun-Guard SN-68 with a light to solar gain ration of 1.83 is widely specified on projects as diverse as schools and auto dealerships to high-rise commercial buildings

and condominiums.

PPG Industries

Rob Struble, manager of marketing and communications, flat glass production

Because of their exceptional solar control characteristics, MSVD applied coatings such as Solarban 60, Solarban 70XL and Solarban 80 glasses are particularly advantageous for commercial buildings, where annual cooling requirements greatly exceed the annual heating requirements, even in Canada’s characteristically cold weather climates. By specifying Solarban products for their commercial structures, building owners in Canada and the US can enjoy significantly greater energy savings than they would with pyrolytically applied passive, low-E glass coatings.

Glass coatings that are applied pyrolytically, such as on Sungate 500 glass, have traditionally been preferred for residential applications in colder, heating dominated climates, such as Canada and the northern US. These glasses, which feature higher shading coefficients, allow more heat to pass into a home. However, as home builders seek to incorporate greater expanses of glass into their residential designs, MSVD coatings have begun to earn favour for their superior solar control and insulating characteristics.

|

| Clarity, solar control and visible light transmittance are combined in PPG’s Solarban 70XL in a clear or colour neutral glass. Photo Courtesy Of PPG Industries. |

AFG Glass

Jon Hughes, manager, architectural glass

AFG’s coated glass products are successful in the residential, commercial and specialty markets. Coated glass products are engineered with specific aesthetic and performance requirements demanded by the various markets. Comfort E2 pyrolytic low-E allows residential homeowners to benefit from the sun’s passive solar energy while controlling heat loss in the winter months. This coating meets the demands of the Canadian Energy Star program, while providing fabricators the advantages of a pyrolytic product. The Sunergy product is a high performance pyrolytic coating. Monolithic and laminated applications in heat dominated climates are excellent applications for this product.

In the commercial market, AFG offers the most extensive product offering by any of the major float glass producers. With six sputter coated spectrally selective low-E glass, architects and building owners are able to select products that meet both the energy and aesthetic requirements. The performance benefit of sputter coated products is that they have been designed to be installed on the #2 surface of an insulated unit, providing for the greatest benefit in controlling the energy from the sun.

The advantage: AFG produces clear and tinted glass products. Because Comfort Ti-AC, Ti-AC40 and Ti-AC23 are available on clear, green, grey, bronze and dark green, with the fabrication benefit of being post-temperable, customers can meet the speed to market requirements demanded by today’s construction.

Viracon

Don McCann, manager of architectural design

Viracon’s target market is high-end buildings within the commercial marketplace. It does not serve the residential market. In the commercial market, we foresee the demand for coated glass products being driven by the expansion of energy codes for commercial buildings. In addition, LEED requirements and Green Building Design are very prominent in this industry and those influence the increased use of coated glass as well.

Cardinal IG Company

Bob Spindler, vice-president, technical services

Cardinal IG supplies its products to the residential window manufacturers.

Pilkington Building Products North America

Scott Hoover, senior manager for architectural marketing

Pyrolytic coated glass enables fabricators to handle the product much like traditional uncoated glass allowing fabricators the ability to temper, insulate and bend much easier than sputter coated products.

|

| The MaRS Centre in Toronto, Ontario, was glazed with one inch insulating glass with Viracon Solarscreen VE1-2M coating on the #2 surface. Photo Courtesy Of Sota Glazing. |

Guardian Industries

Tim Singel, director of residential glass products, and Chris Dolan, director of commercial glass products

High performance coatings that are post-temperable open up many new avenues for growth of fabricators. They can now participate in supplying coated glass on a wide variety of buildings. They can keep more of the ‘value added’ in-house, such as the heat treating, and they can offer much shorter lead times to contractors. Furthermore, products such as Guardian’s Sun-Guard series of coatings can be bent which provides dramatic new design options for architects. The Radio Shack head-quarters in Fort Worth, Texas, is one such example of a building that combines a curving façade with tremendous energy savings. This combination was not possible five years ago.

Viracon

Don McCann, manager of architectural design

While this post-temperable technology has expanded the capabilities of fabricators without requiring them to make the capital investment in a sputter coating line… there are still some limitations on what is available and capable out of this technology. Since Viracon produces its own sputter coatings, it has the ability to offer a wide range of coatings on multiple tinted glass substrates and with silkscreen patterns. Viracon offers more flexibility in glass design with a full cart of options available from a single source.

|

| PPG’s Solarban 70XL glass transmits 63 percent of available visible light permitting only 27 percent of solar energy heat to pass through for a LSG ratio of 2.33 and SHGC of 0.27. Photo Courtesy Of PPG Industries. |

|

| Conventional clear glass transmits 79 percent of available visible light and allows 70 percent of solar energy to pass through, yielding a LSG of 1.13 and a SHGC of 0.70. Photo Courtesy Of PPG Industries. |

Pilkington Building Products North America

Scott Hoover, senior manager for architectural marketing

In recent years, architects and building owners have discovered several issues and concerns regarding maximum visible light products. While those coatings maximized natural day lighting, they also yielded much glare. For instance, office building occupants often have to close their window blinds to see computer screens effectively within their workspaces. The high level of transparency also provides little or no occupant privacy. When viewing the building from the outside, the extreme levels of transparency of these products allow a clear view of desks, stacks of paper, furniture, the backs of file cabinets and so on, which detracts from the design. The view from the outside is excellent, but so is the view into the building.

Many designers discovered that the reality of these glasses were buildings that often had many of the shades drawn, at different levels, resulting in an exterior ‘checkerboard’ effect that was not a design choice, much less a preference. While these products are often specified and seen today in more appropriate areas, there is a current trend moving on to a new, next generation of ‘hybrid’ coatings. Significant coating enhancements of the last couple years have been toward solar control low-E products that provide subtle reflectivity. They have been developed to address the concerns architects and building owners have regarding maximum visible light or transparency coatings.

These hybrid coatings still provide high levels of visible light transmittance, but have a light, crisp ‘shine’. This shine, or subtle reflectivity, provides a more uniform exterior appearance, improves occupant privacy and comfort while reducing interior glare. Many of these products possess excellent solar and thermal characteristics in a single coating, which eliminates the need for an IG unit because increased energy efficiencies can be minimal.

The coatings are applied to clear glass and tints giving architects more design flexibility to utilize colour and/or co-ordinate with other building materials. Aesthetic-wise, while bronze and gray continue to be prevalent, more and more architects are incorporating blues, greens and similar hues so that their buildings better relate to their natural surroundings.

Guardian Industries

Tim Singel, director of residential glass products, and Chris Dolan, director of commercial glass products

Coatings will continue to be developed to improve upon the performance of historical products, providing such things as enhanced solar control or improved handling and fabrication characteristics. Also, expect to see new applications of some existing high performance products, such as Guardian’s ClimaGuard low-E and SunGuard SN-68 coatings, in conjunction with hurricane laminated glass or the improved clarity of coatings such as Guardian’s SN-68 on Ultrawhite glass.

Additionally, expect to see revolutionary new products that provide unique performance such as the remarkable scratch resistance of Guardian’s DiamondGuard coating; the protection of ShowerGuard or the complete UV protection of ClimaGuard SPF. We are really only in the early stages of showing the exciting possibilities of what you can do with glass for homes and buildings.

PPG Industries

Rob Struble, manager of marketing and communications, flat glass production

With the growth of the green building movement, architects and building owners are seeking continually higher levels of solar control and day lighting performance in architectural glass. Recently, PPG responded with the introduction of Solarban 70XL glass – magnetron sputtering vacuum deposition (MSVD) applied coating – which features an unprecedented combination of solar control performance and visible light transmittance.

|

| The PricewaterhouseCooper Centre, formerly called the Canadian Imperial Bank of Commerce, on Madison Avenue in New York, was glazed with Viracon Solarscreen VRE1-46 coating on the #2 surface. Photo By Greg West Photography. |

A light to solar gain (LSG) ratio is critical to architects involved in sustainable building because it quantifies the amount of natural light an architectural glass transmits into a building in relation to the amount of solar energy it keeps out. High visible light transmittance is desired because high levels of day lighting lessen the need for artificial lighting while producing a more pleasant work environment. High levels of solar control, on the other hand, help reduce the demand for air conditioning and other energy-consuming climate controls.

In a standard one inch insulating glass unit, Solarban 70XL glass has a solar heat gain coefficient (SHGC) of 0.27 with a visible light transmittance (VLT) of 63 percent. That equates to a LSG ratio of 2.33 which surpasses, by far, the performance of any other solar control low-E glass on the market.

For the sake of comparison, consider that the least expensive and least technologically advanced type of glazing is a clear one inch IG unit. An IG unit of this type transmits about 79 percent of the available visible light, a highly desirable trait but, unfortunately, allows 70 percent of the sun’s heat energy to pass through as well. The result is a LSG of 1.13. LSG is derived by dividing the glass’ VLT by its SHGC.In the same configuration, an IG unit combining a pyrolytically applied coating of Sungate 500 glass on clear transmits 74 percent of the sun’s visible light along with 62 percent of its heat energy. This generates an LSG of 1.19.

Until recently, one of the best-performing colour neutral solar control low-E glass was Solarban 60 glass, coating applied via MSVD. This glass offers an excellent VLT of 70 percent and a low SHGC of 0.38, which produces a highly desirable LSG ratio of 1.84, a figure that Solarban 70XL glass, nonetheless, out-performs by 21 percent.

The implications of this solar control performance are enormous for architects and building owners. Because of the exceptional solar control characteristics of Solarban 70XL glass, a recent study by an independent energy and environmental research firm showed that specifying it could reduce cooling capacity requirements for some commercial buildings by as much as 26 percent, producing tens of thousands of dollars in savings on HVAC equipment costs.

|

| By glazing the low-E coating on the second surface of an IG unit, instead of the third surface, AFG puts the coating closer to the sun for enhanced solar protection and energy efficiency in its Comfort Ti-AC 40 line of tinted substrates. Photo Courtesy Of AFG. |

In addition to these up-front savings, building operators can reap long-term benefits as well. With Solarban 70XL glass, annual cooling costs can also be cut by three to five percent, producing projected savings of several hundred thousand dollars over a 20 year span.

While Solarban 70XL glass represents a remarkable breakthrough because of its environmental performance, architects also appreciate its transparent, colour neutral appearance, which delivers high levels of natural lighting and increased design versatility. As the green building movement ‘hold sway’ in the architectural and professional building communities, expect architectural glass manufacturers to continue developing products that enhance both the energy performance and the aesthetic appeal of their products.

AFG Glass

Jon Hughes, manager, architectural glass

Trends in glass technology for the residential and commercial markets today are to engineer products that meet the functional and performance requirements demanded by building owners, while meeting the demands that the fabrication process has put in place: speed, durability and post-temperability.

Advances in more spectrally selective sputter coated low-E products, the combination of low-E coatings with low maintenance coatings and electro-chromic glass products will continue to evolve over the next several years.

Specialty coatings for the display and energy markets are rapidly evolving in a segment which is experiencing tremendous growth.

Viracon

|

| A cutaway illustration of a generic Cardinal LoE3 film stack. Cardinal uses sputtered technology for its low-E coatings for very low-emissivity, significantly reducing the SHGC, which also reduces solar gain and air conditioning costs. Graphic Courtesy Of Cardinal IG. |

Don McCann, manager of architectural design

The trends will reveal an expansion of products ‘within’ the current coating technologies established… in that, there will be breakthrough coating types developed within the sputter coating process.

Cardinal IG Company

Bob Spindler, vice-president, technical services

Watch for trends in coated glass technology for developing temperable sputtered coatings, sputtered coatings that have lower SHGC and emissivity, double and new triple silver layered products and easy-to-clean (photocatylic) glass coatings either pyrolytic or sputtered. -end-

Special thanks to Ray Wakefield from Trulite Industries, Mississauga, Ontario, for technical support.

Assistance provided by correspondents, marketing and media relation specialists: Michael Driehorst, The Lauerer Markin Group; John Millea, Yearick-Millea; Amy Hennes, communications, Guardian Industries; Sara Theis, senior market analyst, Viracon.

Article compiled and edited by Chris Skalkos, editor, Glass Canada.

Print this page