Features

Software

Architectural design

Business intelligence

BIM for curtainwall systems: Effectively meeting the BIM requirement to benefit your business

Effective use of 3D modelling is good for business.

August 19, 2020 By Jay Polding

Photo credit: © Panuwat Sikham / Getty Images

Photo credit: © Panuwat Sikham / Getty Images Building Information Modeling has become the gold standard in the building industry over the last 20 years. Building owners and investors expect to see 3D digital models before a shovel goes in the ground and beyond. They feel that the BIM method will result in a more predictable budget and delivery date as well as a better way to manage their building assets post-construction. This has resulted in a sharp increase in Requests for Proposals which require BIM. How can you effectively meet the BIM requirement and gain benefits to your business?

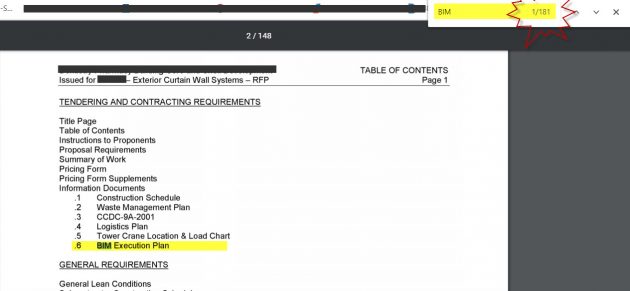

Pictured here is an RFP for a current project (as of the printing of this article). The word BIM is mentioned 181 times in the Curtain Wall Systems spec.

The BIM execution plan

Often a BIM execution plan is specified in the RFP. This document is typically developed by the prime consultant, often the architect. The BIM execution plan’s purpose is to define the overall goals of BIM on a specific project. It seeks to define the why, who, what, how and when. Often, this information is defined in a table called LOD matrix. This table defines how detailed your 3D model needs to be.

Many curtainwall systems companies already use advanced software like Autodesk Inventor or Dassault Solidworks to design detailed 3D models, extract bill-of-materials and send plans and code to the shop floor. So, why do these files not usually fulfill the requirements of the BIM execution plan? It comes down to computing power and the differences in software.

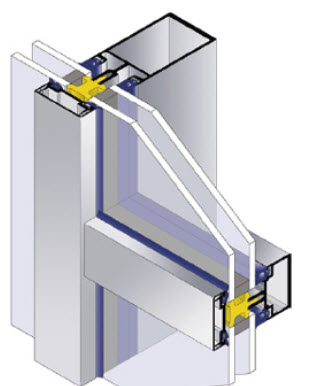

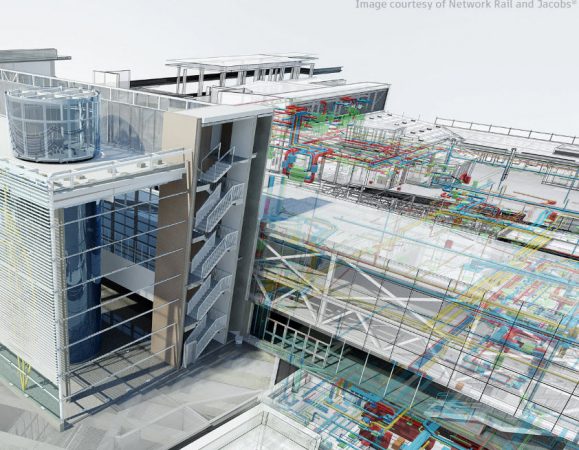

In a curtainwall system there can be hundreds of units and glass panes, thousands of mullions, screws and a lot of insulation and sealant. One by one, the computer can easily handle these objects. Add them all together in one file and you have a very slow model, perhaps even crashing the computer. The architect’s Revit model contains the curtainwall system as well as all the other systems like structural, mechanical, electrical, plumbing, interior finishes and more. Therefore, it is necessary to reduce the detail of each of these components to their essential dimensions so the building can be displayed in one file without slowness or crashes. Even in the current CAD workflow, shop drawings for the architect often are at a reduced detail compared to the shop drawings that go to the shop floor. This carries through to BIM.

Typical Inventor or Solidworks file detail. (Photo: Kawneer)

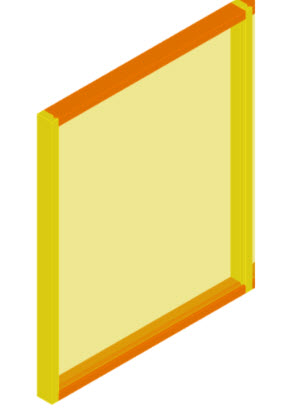

Typical Revit file detail. (Photo: Autodesk)

Level of detail and development

LOD 300

The curtainwall system must be integrated with many other systems in the building. Since the architect and engineers are often using Revit, they require that most consultants, including curtainwall systems companies, provide Revit files for coordination. To manage the size of files, the Revit model detail is defined in the LOD matrix which is found in the BIM execution plan.

The LOD standard was developed by the American Institute of Architects and is managed by a group called BIMForum. The LOD standard ranges from 100-500. Curtainwall systems companies are in the LOD 300, 350 and 400 range. (A full description of the LOD specification can be found on the BIM Forum website, bimforum.org.)

LOD400

The detail jumps quite quickly from basic to complex. Many shop drawing packages for architects are required to be LOD 300 which is comparable to the detail provided by 2D CAD. LOD 300 provides the most flexibility to change while not compromising quality. Exceptions to this might be requested, like providing 3D anchor locations. Many have found it useful to integrate their existing 2D CAD extrusion details into the 3D Revit model to provide that extra level of detail. A considerable amount of effort is added when all curtainwall systems are required to be modelled at LOD 400.

How and when files are exchanged

The BIM execution plan defines how and when files are to be exchanged. How files are exchanged can range from the current methods of email and FTP to cloud Common Data Environment sites like BIM360. The BIM execution plan may define how often a 3D model is required to be uploaded. This ranges from uploads and downloads at key milestones, to bi-weekly uploads and downloads, to a live link inside of BIM360 design with changes seen instantly. The CDE provides a place for non-technical people to view and markup drawings and models on mobile devices without having to know complex software.

Benefits for curtainwall systems companies

The opportunities of BIM are more than winning an RFP. Much benefit can be found in extracting data from the BIM models. Curtainwall systems have many parts, whether they are stick-built or unitized. Counting, scheduling, optimizing and ordering all these parts has historically required much effort. This challenge is met very well by BIM technologies. Most BIM tools, like Revit, can provide immediate, live data for estimation and ordering.

Another benefit is reducing onsite waste and time by digitally templating and measuring. An accurate point cloud scan of a building can be brought right into Revit, Inventor, Solidworks and other systems. This enables a digital template to be built to precise, real world, measurements. Further, these digital point clouds and templates can be shared with others in any part of the world.

BIM data can be re-used for your manufacturing processes. For instance, key points from Revit can be linked into Inventor or Solidworks to assist in building the shop-floor drawings and data.

Cloud technologies like BIM360 can allow for quality control to extend to the field. Using their mobile devices, installers can access the latest plans and request information based on videos and pictures they take on site.

Digital transformation has accelerated in recent times. BIM is a foundational technology which other opportunities grow out of. Software companies like Autodesk, Trimble and Nemetschek are investing billions in the digital transformation of the construction industry. Many students are coming out of school with the desire and knowledge to use these digital tools. With a proper technology strategy, curtainwall fabricators are exceeding expectations and reaping the rewards of using BIM. •

About the author

Jay Polding is an industry account manager at AEC with SolidCAD. He has 20 years of AEC industry experience both in Canada and internationally.

Print this page