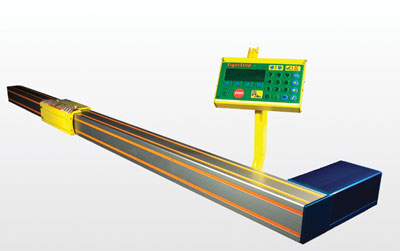

Measuring cuts can be quick and easy with a TigerStop lineal positioner.

Automatic positioning

|

|

Measuring cuts can be quick and easy with a TigerStop lineal positioner. TigerStop automates your existing equipment with simple, affordable technology made to grow with you. TigerStop goes to the exact position quickly and accurately with the push of a button. All the operator does is set it and forget it. Wakefield Equipment also offers a full line of TigerStop-equipped up-cut, chop and V-notch saws from CTD Machines and Atech Machinery. These are versatile, heavy-duty, industrial saws built with top components to ensure long-lasting accuracy for years to come.

www.wakefieldequipment.com

Lifting made easy

|

|

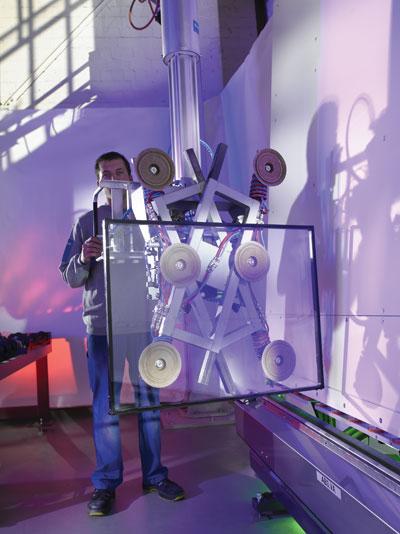

Bystronic one-column lifts simplify glass handling thanks to their low dead weight and rigid guidance. The vacuum lifters are used in an X-Y craneway or slewing crane. All functions of the lifting equipment with a column are achieved pneumatically. The vacuum lifting technology works using Venturi nozzles. Since 1998, Easy-Lift has been popular in the glass processing industry. More than 1,500 pieces of equipment sold speak for themselves. The Easy-Lift is available for loads of up to 500 kilograms. In the standard version it is equipped with a pneumatic turning and tilting function as well as a pneumatically height-adjustable control unit. The integrated automatic economy operation for vacuum creation reduces energy consumption.

www.bystronic-glass.com

|

|

Economical IG

The Erdman 400 Series line of equipment is a simple and economical solution to your IG production needs. This low-cost insulating glass production system works with all flexible spacer systems applying your spacer straight with true 90-degree corners. Minimal operator training and no data input is required for standard operation. The 400 Series spacer applicator with a tilting grid muntin station, roll press and 400 Series secondary sealer pictured above is capable of producing more than 400 units per shift with two entry-level operators. The 400 Series performs straight-line application of spacers with true 90-degree corners and minimal operator training or expertise required. No data input is required for standard operation, and operators can run shapes or units manually. The machine has a small footprint of 12 feet by 30 inches.

www.erdmanautomation.com

|

|

Four-point welder

The AKS 1900 from Urban is designed as an economic, vertical, four-point welder for vinyl window frame or sash profiles. The weld seam limitation is two mm. An optional 0.2 mm tight pinch is possible with special features. The machine is available in left-hand fixed or right-hand fixed configurations for flexible line layout.

Flexible fixture configurations include a standard quick-change system, optional separate top and bottom tiers or optional independent doublestack clamping. The welding heads are driven on a strong linear ball rail system. Maintenance is easy due to the accessible and numbered components, the real-time temperature monitoring, the maintenance menu with full self-diagnostics and the tool-less quick-change weld fixture and Teflon systems. The bottom heads are fixed and the top insertion height can be changed based on frame height for ergonomic loading and unloading. The AKS 1900 includes an industrial PC with a Windows XP user interface. A touchscreen interface is available on request. Data input is via manual keypad entry or download from 3.5-inch floppy disk, USB stick or network connection. Bar code reading capabilities are available on request.

www.u-r-b-a-n.com

|

|

Wide range of products

Olbricht, from Hamminkeln-Brunen Germany, concentrates in glass automation and handling equipment for the architectural, automotive, appliance, photovoltaic and specialty glass industries. Available equipment includes loading and unloading for machines and automated lines, handling systems for flat and curved glass, CNC cutting machines for flat and curved glass, automatic breakout and grinding systems, laser and grit-blast edge deletion systems, robotic inspection vision and stacking systems, automated packing systems with interleave paper, automated laminated glass and parts assembly systems and custom, one-of-a-kind, assembly systems.

www.cassosolartechnologies.com

|

|

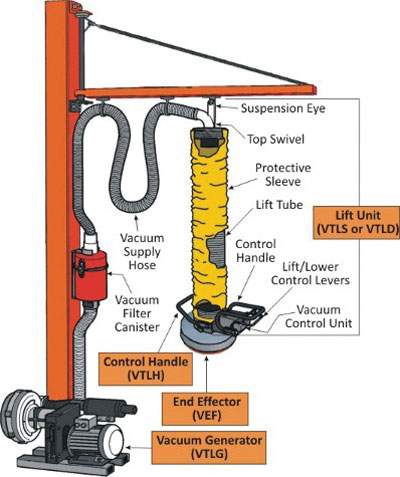

Tube lifter

Vantage Series tube lifters from Wood Powr-Grip are designed to be easy to use and to speed production. Productivity and operator safety are enhanced because of the Vantage’s ergonomic and easily configurable features. Using heavily constructed Vantage Series lifters can reduce load damage and lower investment and service costs. Wood’s Powr-Grip’s Vantage Series lifters comprises four basic components: a lift unit, a vacuum generator, a rigid or flexible control handle, and an end effector. Interchanging these components makes these lifters suitable for nearly any application. Maximum load capacity for the Vantage Series is 440 pounds, minimum load capacity is 65 pounds. The Vantage Series is for flat-to-flat load movement only. Available accessories and options include quick disconnects, drop protection valves, angle adapters, bottom swivels, extended release valves, standard release valves, universal joints, a noise-reducing enclosure and large filters.

www.powrgrip.com

|

|

Gantry glass handling

The PKL/SBL series from LiSec is a gantry system with electronically controlled floor drive units that runs on flat guide rails or directly on concrete floors. The automatic drive synchronization is controlled by optical sensors and ensures exact positioning of the loading system relative to the receiving station. The robust bridge drive system ensures exact positioning of the double suction frame and is available in rotating or tilting versions. It features process-controlled operation from pickup of large-sized sheets through to transfer to the turning table. A special high-speed version is also available with multiple drives and precision guides for the floor and gantry movement along with optimized handling and travel procedures. The PKL/SBL system supports up to 60 loading positions. Double-sided tilting and rotating suction frames are available. The control produces optimized travel routines for the shortest possible cycle times. It is available in half- and full-gantry versions.

www.lisec.com

|

|

Fluid dispensing system guide

Dymax Corporation has released a new selector guide for manual and automated fluid-dispensing systems. This comprehensive guide provides detailed product information and is organized in a manner that makes comparison easy. Specifications such as dispense modes, viscosity range and material compatibility are included, as well as the type of supply reservoir that each unit can accommodate. The guide is available for download on the Dymax dispensing equipment webpage.

Dymax, in alliance with some of the world’s leading dispensing companies, has developed high-quality, field-proven dispense systems to fit many dispensing applications. These systems include various automatic and manual dispensing systems, spray valves and related components for seamless integration into the assembly process. Dymax Application Engineers are available to help create the best dispensing solution for the application.

www.dymax.com

Efficient glass washing system

The founder of Best Makina started working as a European glass machinery technician and created his first machine for glass in Europe in 1985. With over 100 employees, the company is able to rapidly manufacture quality machines due to its experience. In 2004, the enterprise received an accreditation of the ISO 9001 norm and Best Makina is present in all glass-specialized expositions around the world. Best Makina’s product line includes complete IG-unit fabricating CNC equipment, horizontal butyl extruders for spacers, two-component hydraulic pumps, automatic spacer-bending machines and manual or automatic roller conveyors. The BWPL is one of Best Makina’s CNC glass washing machines. The roller conveyors, water pumps and brushes are all automatically started to save energy. To wash the glass, the machine uses highly pressurized water injection along with polyamide brushes. The BWPL is also equipped with energy-efficient air knives to effectively dry the glass. This glass washing machine’s daylight illuminators also consume low amounts of energy. A complete cycle only takes 25 seconds to complete per glass unit and the BWPL has an extra conveyor rack to increase productivity and for processing oversized glass. This machine will also do double, triple, stepped and facade glazing. In addition, it will automatically detect the unit’s dimensions and will adjust the pressure settings accordingly. This model also comes with a tilting table for oversized glass unloading.

www.bestmakina.com

Print this page