Technology

Machinery

Optical solar glass inspection from Isra Vision

January 11, 2012 By Isra Vision

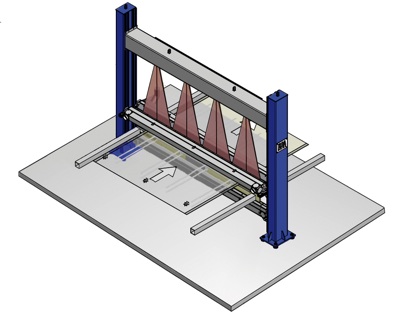

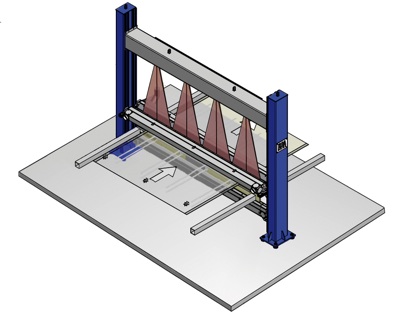

The new Patternscan offers a 100 per cent-optical, in-line inspection of solar glass. Patternscan-Ribbon inspects uncut pattern glass, Patternscan-Sheet performs inspection of pattern glass sheets. Both systems apply the innovative multi-mode and multi-view lighting technologies developed by Isra Vision. Multi-View indicates a variety of possible positions of lights on the camera bank. Multi-Mode is the term for different lighting modes. Combined, these technologies enable recognition and differentiation of all defects in the glass, on the glass and along the glass edges, as well as in the glass coating.

The new Patternscan offers a 100 per cent-optical, in-line inspection of solar glass. Patternscan-Ribbon inspects uncut pattern glass, Patternscan-Sheet performs inspection of pattern glass sheets. Both systems apply the innovative multi-mode and multi-view lighting technologies developed by Isra Vision. Multi-View indicates a variety of possible positions of lights on the camera bank. Multi-Mode is the term for different lighting modes. Combined, these technologies enable recognition and differentiation of all defects in the glass, on the glass and along the glass edges, as well as in the glass coating.

The new Patternscan offers a 100 per cent-optical, in-line inspection of

solar glass. Patternscan-Ribbon inspects uncut pattern glass,

Patternscan-Sheet performs inspection of pattern glass sheets. Both

systems apply the innovative multi-mode and multi-view lighting

technologies developed by Isra Vision. Multi-View indicates a variety of

possible positions of lights on the camera bank. Multi-Mode is the term

for different lighting modes. Combined, these technologies enable

recognition and differentiation of all defects in the glass, on the

glass and along the glass edges, as well as in the glass coating.

Through the advancement and development of the software

platform, both Patternscan systems guarantee the highest quality of pattern

glass according to market standards in the photovoltaic industry. The

differentiation between defects, including open and closed bubbles, as

well as the smallest defects and scratches (independent of their

orientation) is one of the standard features of the modular kit. In

short, defects previously classified as invisible and undistinguishable

can now be detected and classified with the help of Patternscan.

|

|

|

A

theoretically unlimited number of different views can be simultaneously generated with just one camera or camera bank. |

The patented unit is made up of extremely fast, individually switchable

LED’s, which are being used together in this form for the first time. A

theoretically unlimited number of different views can be simultaneously

generated with just one camera or camera bank. This technology enables a

so far unreached inspection performance regarding defect detection and

classification.

The inspection software uses the collected defect data from the

individual views, which are provided in real time, for complete,

reliable defect classification. Based on this defect classification, cut

optimization is possible in a way which will significantly increase

yields across the whole production line and saves material. The user

profits from the results with an enormous increase in performance, and

at the same time, a significant reduction in the necessary hardware. The

low operating costs of Patternscan-Ribbon and Patternscan-Sheet systems

provide increased profitability and optimization of processes. The

system therefore closes what had been a significant gap between the

technical requirements for inspection and short ROI times for such

systems.

Related links

Isra Vision

Print this page