Carbon assessment service

dow.com

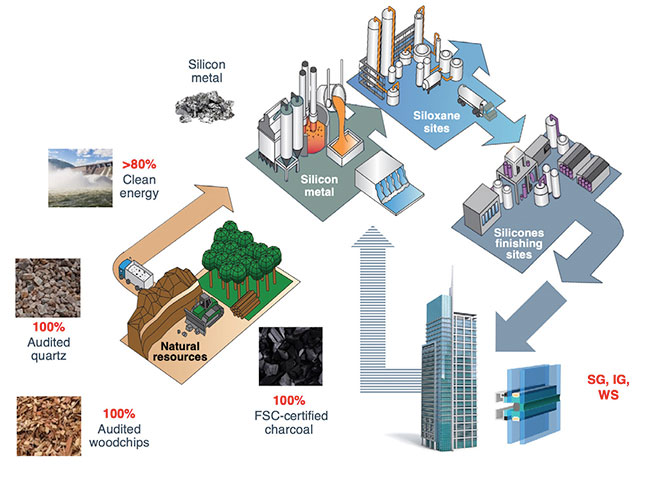

The first-ever carbon neutrality service is now available for silicones used in structural glazing, insulating glass and weathersealing applications on high-performance building facades. Produced in compliance with the internationally recognized PAS 2060 verified carbon neutrality standard, Dow carbon-neutral silicones for building facades can support green-building design initiatives, enhance facade sustainability and improve green-building ratings. Architects and building designers can request the Dow Carbon-Neutral Silicone Service for Building Facades on specific projects globally that involve Dow carbon-neutral silicones. Documentation and project support tools include:

- Environmental Product Declarations for life-cycle environmental assessment of products

- Externally audited carbon dioxide certificates, following the PAS 2060 standard for verified carbon neutrality

- Life Cycle Analyses to show the positive environmental impact of carbon neutrality

- Product specifications for use in submittals

- COOL 4.0 project management tools with integrated carbon neutrality services on specific projects

- Building Science Connect, an online showcase of Dow products, services and innovations

Dow Carbon-Neutral Silicone Service for Building Facades includes the following Dow carbon-neutral silicones: Dowsil 983 silicone sealant (two-part structural), Dowsil 3363 silicone sealant (two-part insulating glass), and Dowsil 795 silicone sealant (one-part weathersealing). Dow has announced it will build the world’s first net-zero carbon emissions integrated ethylene cracker and derivatives site in Fort Saskatchewan, Alta. The organic, brownfield investment would significantly increase Dow’s capacity of advantaged ethylene, polyethylene and derivatives manufactured across Alberta. Canadian glazing contractors assessing embodied carbon in their projects further benefit from products produced and shipped domestically.

Adds green points

tremcosealants.com

The high-modulus and outstanding physical properties of Tremco’s SG300 allow for sealing a wide variety of demanding applications such as four-sided structural glazing curtainwalling and joints within the curtain/window system. Basic uses include curtainwalling, including cap, toe, heel and air seals; general sealing and jointing; silicone structural glazing in two-sided systems; a weather seal in butt (two-sided) and stopless (four-sided) glazing systems; and joints within curtain/window systems.Tremco Construction Products Group Asia Pacific was granted the Low Carbon Footprint certification for SG300 single-component, neutral-cure silicone sealant earlier this year. The certification by the Korea Environmental Industry and Technology ascertains that the greenhouse gas emissions produced from the entire life cycle (manufacturing, transport, distribution, use and disposal) of the SG300 silicone sealant is less than the average emissions of products in the same category. In Korea, construction works for new commercial buildings are required to have green building certification.

Backed By EPDs

vitroglazings.com

Vitro Architectural Glass has published updated versions of its Environmental Product Declarations for both flat and processed glass. These updates re-affirm that Vitro’s glass products contain less embodied carbon than the industry standard for architectural glass products and indicate a lower embodied carbon value than previously reported in 2017 editions of these EPDs. EPDs offer detailed data about the embodied carbon values and life-cycle impact on the environment of a wide range of architectural building products, including information about the extraction, transportation and processing of related raw materials, and can be used as credentialing documentation for sustainability certifications such as the U.S. Green Building Council’s Leadership in Energy and Environmental Design certification. As a standard measure of embodied carbon, EPDs calculate a value of global warming potential that is expressed as kilograms of carbon dioxide equivalent. In 2017, Vitro first published third-party verified EPDs for its flat glass and processed glass products. In 2019, the National Glass Association published an architectural glass EPD that evaluated the embodied carbon of clear, low-iron and tinted flat glass produced by four member companies of the NGA’s Forming Committee, including Vitro. Its findings suggested an industry average GWP of 1,430 for comparable products. Vitro’s 2023 EPDs indicate that its products contain just 1,350 kilograms of carbon dioxide equivalent, which is six percent lower than the NGA’s industry standard figure and an improvement on figures reported in 2017. Vitro’s lower GWP was driven by several key steps taken by Vitro’s production teams to lower embodied carbon generated during glass production.

Vitro Architectural Glass has published updated versions of its Environmental Product Declarations for both flat and processed glass. These updates re-affirm that Vitro’s glass products contain less embodied carbon than the industry standard for architectural glass products and indicate a lower embodied carbon value than previously reported in 2017 editions of these EPDs. EPDs offer detailed data about the embodied carbon values and life-cycle impact on the environment of a wide range of architectural building products, including information about the extraction, transportation and processing of related raw materials, and can be used as credentialing documentation for sustainability certifications such as the U.S. Green Building Council’s Leadership in Energy and Environmental Design certification. As a standard measure of embodied carbon, EPDs calculate a value of global warming potential that is expressed as kilograms of carbon dioxide equivalent. In 2017, Vitro first published third-party verified EPDs for its flat glass and processed glass products. In 2019, the National Glass Association published an architectural glass EPD that evaluated the embodied carbon of clear, low-iron and tinted flat glass produced by four member companies of the NGA’s Forming Committee, including Vitro. Its findings suggested an industry average GWP of 1,430 for comparable products. Vitro’s 2023 EPDs indicate that its products contain just 1,350 kilograms of carbon dioxide equivalent, which is six percent lower than the NGA’s industry standard figure and an improvement on figures reported in 2017. Vitro’s lower GWP was driven by several key steps taken by Vitro’s production teams to lower embodied carbon generated during glass production.

Low-carbon aluminum

hydro.com

Hydro Reduxa is low-carbon aluminium. Using renewable energy from water (hydro power), wind and solar, the company produces cleaner aluminium, reducing the carbon footprint per kilogram of aluminium to four, which is less than a quarter of the global average. At its Karmoy plant in western Norway, the whole energy supply comes from Hydro’s hydro power plants in nearby Roldal-Suldal, meaning that the whole operation is virtually self-sufficient.

Hydro Reduxa is available in low-carbon extrusion ingots, low-carbon foundry alloys, low-carbon sheet ingots and low-carbon wire rod. Hydro Reduxa is verified according to ISO 14064 by DNV GL, covering all carbon emissions from bauxite mining and alumina refining to the production of aluminium in electrolysis and casting.

No performance compromise

saint-gobain-glass.com

The extremely selective solar control product family Cool-Lite Xtreme is available on Orae substrate, the new low-carbon glass of Saint-Gobain Glass. With Orae, Saint-Gobain Glass has achieved a landmark technical breakthrough enabling it to offer the glass with the low embodied carbon for the facade market thanks to a substantial R&D effort and the excellence of its industrial teams. This innovation will help to significantly reduce the carbon footprint of construction and accelerate the development of the circular economy. Intended for use in the glazed parts of a facade, Cool-Lite Xtreme Orae is an effective response to the stricter sustainability requirements of the building industry without any compromise on technical or esthetic performance. Cool-Lite Xtreme Orae provides the best of both embodied and operational carbon levels, thanks to the exceptionally low carbon footprint of Orae, produced by combining high recycled glass content (64 percent according to ISO 14021:1999) and renewable electricity. As a result, the new product offers a low carbon footprint with a reduction of 42 percent compared to regular products. The excellent energy performance of Cool-Lite Xtreme coatings, also drastically reduce carbon emissions generated by energy consumption when used on buildings, thanks to their high performance in terms of daylight intake, solar control and thermal insulation. In line with Saint Gobain’s resolute dedication to innovation and sustainability, Orae has been certified with the “Solar Impulse Efficient Solution” label by the Solar Impulse Foundation. Orae joins the other 1,500 efficient solutions’ that have successfully completed thorough evaluations under the Solar Impulse Foundation initiative. Independent experts have assessed the glass in regard to various aspects including feasibility, scalability, environmental impact, and profitability. A verified EPD confirms Orae sets a new standard at 6.64 kilograms of carbon dioxide per equivalent meter squared. Orae has been integrated into Calumen, Saint Gobain’s digital glazing configuration tool.

The extremely selective solar control product family Cool-Lite Xtreme is available on Orae substrate, the new low-carbon glass of Saint-Gobain Glass. With Orae, Saint-Gobain Glass has achieved a landmark technical breakthrough enabling it to offer the glass with the low embodied carbon for the facade market thanks to a substantial R&D effort and the excellence of its industrial teams. This innovation will help to significantly reduce the carbon footprint of construction and accelerate the development of the circular economy. Intended for use in the glazed parts of a facade, Cool-Lite Xtreme Orae is an effective response to the stricter sustainability requirements of the building industry without any compromise on technical or esthetic performance. Cool-Lite Xtreme Orae provides the best of both embodied and operational carbon levels, thanks to the exceptionally low carbon footprint of Orae, produced by combining high recycled glass content (64 percent according to ISO 14021:1999) and renewable electricity. As a result, the new product offers a low carbon footprint with a reduction of 42 percent compared to regular products. The excellent energy performance of Cool-Lite Xtreme coatings, also drastically reduce carbon emissions generated by energy consumption when used on buildings, thanks to their high performance in terms of daylight intake, solar control and thermal insulation. In line with Saint Gobain’s resolute dedication to innovation and sustainability, Orae has been certified with the “Solar Impulse Efficient Solution” label by the Solar Impulse Foundation. Orae joins the other 1,500 efficient solutions’ that have successfully completed thorough evaluations under the Solar Impulse Foundation initiative. Independent experts have assessed the glass in regard to various aspects including feasibility, scalability, environmental impact, and profitability. A verified EPD confirms Orae sets a new standard at 6.64 kilograms of carbon dioxide per equivalent meter squared. Orae has been integrated into Calumen, Saint Gobain’s digital glazing configuration tool.

Holistic approach

agc.com

AGC Glass Europe has started production of low-carbon Planibel Clearlite, a float glass whose carbon dioxide footprint has been slashed by more than 40 percent. The production of low-carbon Planibel Clearlite yields no more than seven kilograms of carbon dioxide per meter squared for glass that is four millimeters thick. The glass is being produced in France and Belgium with plans for a worldwide rollout. With this additional production capacity now online, AGC has expanded its low-carbon glass range to include a low-carbon variant of Stratobel (safety glass), Stratophone (acoustic glass), Iplus (thermal insulation glass), Stopray and Energy (solar control glass), as well as toughenable coatings (T-coatings). The entire range is now available in all thicknesses from three to 10 millimeters.

AGC Glass Europe has started production of low-carbon Planibel Clearlite, a float glass whose carbon dioxide footprint has been slashed by more than 40 percent. The production of low-carbon Planibel Clearlite yields no more than seven kilograms of carbon dioxide per meter squared for glass that is four millimeters thick. The glass is being produced in France and Belgium with plans for a worldwide rollout. With this additional production capacity now online, AGC has expanded its low-carbon glass range to include a low-carbon variant of Stratobel (safety glass), Stratophone (acoustic glass), Iplus (thermal insulation glass), Stopray and Energy (solar control glass), as well as toughenable coatings (T-coatings). The entire range is now available in all thicknesses from three to 10 millimeters.

AGC Glass Europe has taken the next step in its carbon neutrality roadmap by enabling another AGC production facility to produce low-carbon glass. The group’s holistic approach takes the entire value chain into account: decarbonising production processes, reducing carbon dioxide emissions from the upstream supply chain and cutting other indirect emissions. AGC is effectively leveraging the more sustainable procurement of raw materials; the use of highly efficient melting furnaces that deploy innovative electroboosting technology; the increased use of recycling via intelligent pre-consumer cullet flows; and optimised transport between AGC plants and customers. The group also promotes the use of renewable energy by not only purchasing green energy but also generating its own green solar and wind power.

Print this page