Technology

Films, coatings & laminate

Glass laminating technology showcase

January 30, 2019 By Glass Canada Staff

As glass gets larger and architects get more creative, new technology in interlayer and laminating is helping us to meet the challenge

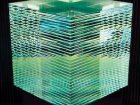

Load-bearing

finnglass.com

Finnglass has developed a 50-centrimetre-thick laminate to open possibilities for architecture and design. This newcomer in the glass industry was developed as a response to a challenge to enable more ambitious use of glass in architecture. The end result is a horizontally stacked multilayer laminate that lets light, shadows and moving shapes be seen through translucently, while being suitable to be used as a load-bearing structure. What started as a need from architects and designers has led to the development of a 50-centrimetre-thick laminate composed of 31 layers of tempered, ultra-clear Pilkington Optiwhite glass, with each layer 15 millimetres thick. Once the layers are assembled together, the strength of the resulting laminate can challenge concrete. Thick laminate gives architects and designers new possibilities to realise their artistic visions without compromising the beauty and simplicity of glass with supporting concrete or steel structures. It all began when architects found it hard to find solutions that allowed for more ambitious use of glass in load-bearing structures and state-of-the-art facades. When such constructs seemed hard to build with existing products and methods, European firms challenged the glass industry to develop a solution to meet demand.

“We took on the task, seeing increasing potential for the use of structural glass in the construction business,” says Timo Saukko, CEO of Finnglass. “We leveraged our expertise in glass processing and heat transfer models to solve problems, such as how to transfer heat into the massive laminate structure during the manufacturing process. It took a combination of technical problem-solving and hands-on experience to put the solution into practice. Our showcase piece of thick laminate is just an example of what we can achieve in this field.”

In the future, Finnglass will be optimizing its manufacturing processes and pursuing opportunities to demonstrate the value of thick laminate in constructing architectural masterpieces along with further growing their decades-long experience in applying electrically heated glass in diverse demanding architectural projects.

Resistance to heat and aging

salemdist.com

Salem Flat Glass and Mirror, in partnership with Folienwerk Wolfen, brings a premier EVA film to North America: EVGuard. Ethylene-vinyl acetate, or EVA, is a copolymer best known for its outstanding resistance to heat and aging. EVGuard is a special EVA film for laminated glass and laminated safety glass that is tailored especially to the high demands of architecture and interior design. The Folienwerk Wolfen company is a pioneer in the processing of EVA films. EVGuard was developed, and is manufactured, in Germany with European raw materials. Laminated glass manufactured with this premium laminating film has been tested extensively in Europe and the U.S. as well as in regions with extreme climatic conditions. Thanks to its safety properties, high-performance EVGuard EVA film is especially suited for laminated safety glass and sound insulation glass. Its high elasticity and adhesion also make this innovative product perfect for use in burglary protection and safety barriers. EVGuard is the result of years of research and development and exhibits its superior properties as it forms a full crosslinked composite layer for long-lasting fade resistance, stronger resilience over time and no delamination. It is certified for impact, weathering and sound reduction and meets all U.S. standards.

Decorative options

agcglass.com

Colour and privacy are strong-points of the laminated safety glass Stratobel Colour from AGC. From transparent via translucent to opaque, this glass offers coloured light transmission as desired through the use of multiple films. In architectural projects this provides the possibility to design artistically using transparency both in the interior and externally, and to combine colour with aesthetics and security. The colour tones – Stone Grey, Mineral Grey and Terra Brown – add harmonically to the decorative glass range. The interplay of these colour tones has been brought to life in the form of rotatable glass fins. Decorative glass types Lacobel T and Matelac T are also available and offer many opportunities for combinations. The products are perfectly colour-matched across the Stratobel Colour range. Individual colour tones for decorative and laminated safety glass can be created via the online service My Colour for an order volume of 200 square metres and above.

Low yellowness

trosifol.com

Kuraray’s Trosifol business is a leading global specialist in the development, manufacture and supply of PVB and ionoplast interlayers for laminated safety glass in architectural applications. With the acquisition of the DuPont Glass Laminating Solutions business in 2014, Trosifol PVB and SentryGlas ionoplast provide the broadest range of interlayer solutions in the market. The Trosifol portfolio’s innovative glass-laminating solutions include structural and functional interlayers for safety, security and hurricane resistance, sound insulation and UV protection. In glass railing and canopy applications, SentryGlas ionoplast interlayer has proven to be the premier product with its post-glass breakage performance and edge stability in exterior projects. For decorative applications, Trosifol offers coloured interlayers for interior design projects and shower enclosure applications. Trosifol UltraClear and SentryGlas exhibit the lowest yellowness index in the industry for low-iron glass applications.

Enhanced strength

everlam.com

While the growing trend for very large glass panels makes beautiful buildings, it also creates technical challenges, key among which is ensuring the strength of the glass panels. Everlam Super Tough enables architects and designers to unleash their creativity. Everlam Super Tough is Everlam’s extra-resistant PVB solution, which provides extra strength and safety in applications where safety can’t be traded, such as glass balconies, balustrades, curtainwall, floors and stairs. It offers outstanding structural stability by making the glass stronger, so that thinner glass can be used to minimise the weight and cost of the entire glass structure. Should a glass panel break, Everlam Super Tough will maintain broken glass fragments firmly in place for a longer time than standard PVB. The product is manufactured according to the Everlam standards of absolute quality and performance consistency and can be processed on a standard lamination line, which represents a clear benefit for laminators. Other Everlam PVB solutions include Clear, White, Color and Quiet.

Greater uniformity

glaston.net

The ProL-zone full convection laminating furnace upgrade from Glaston is designed to be a quick and cost-efficient modification for your existing laminating line. The upgrade replaces a damaged or outdated heating chamber. Glaston has made ProL-zone as easy as possible to operate. The process is practically recipe-free. Fabricators only need to put in one parameter and the rest will take care of itself. No more trial and error with juggling a number of variables. The very concept of ProL-zone is based on reaching a production capacity balance with low-E and clear glass. ProL-zone uses full convection technology, which does not differentiate between glass types or product modes. The convection system provides extremely even heat uniformity, giving users consistently superb glass quality and an up to a 100 per cent capacity increase compared with traditional infrared heating. ProL-zone’s full convection technology gives the operator the best possible control over the chamber temperature. This eliminates heat loss, which means considerable savings in energy costs.

Automate the process

intermac.com

Genius LM is a range of cutting tables from Intermac for laminated glass aimed at companies that wish to automate their laminated glass cutting processes, and which require superior ease of use and an intuitive approach to machining for all glass thicknesses. The Genius LM family is designed to facilitate the handling of glass sheets and of the machine crosspiece, significantly improving productivity. A short-wave lamp warms the plastic film without overheating the glass. At the same time, the upper cutting bridge ensures that a portion of the sheet is held in place by pressing down on it and a suction cup bar, which is pressed against the underside of the glass, enables the separation of the finished volume. The grinder coating removal device can remove low-E film with a 20-millimetre diameter cup grinder. It delivers constant removal quality, thanks to automatic grinding wheel wear compensation. When integrated with smart software, Intermac solutions serve to minimise operator intervention, ensuring a clearer overview of the entire process, as well as greater levels of safety. The operator interface is simple and intuitive and enables cutting programs generated by many of the optimisers present on the market to be imported, courtesy of the integrated Optimiser Transferring Data universal interface that automatically defines cutting parameters and generates the program for the cutting table.

Aligned with trends

hhhtempering.com

Glass laminating machines from HHH Tempering Resources helps diversify glass fabrication offerings and keeps fabricators aligned with current glass industry trends. HHH technology can process glass down to 71 by 94 inches in thicknesses from three to 19 millimetres. Speeds from 0.5 to five metres-per-minute are possible, generating production capacities from 1.5 to two hours per cycle. HHH laminating machines are built with strong, stable materials and all electrical work is UL-approved. The independent control cabinet and touchscreen display each working stage.

Complete control

billco-mfg.com

Billco’s Lami-Pro is a customizable laminating assembly line built for producing high quality laminated glass. The line is designed to clean glass, assemble, laminate, heat and pre-press the unit prior to autoclaving. Available conveyor widths are 60, 84, 96 or 108 inches. Glass thickness range is 2.2 to 19 millimetres with processing speeds from five to 26 feet per minute. Maximum laminate thickness is three inches. The modular design allows for custom line configurations and drop-in replacement options. Precision recipe line control simplifies operations and maintains complete control of all aspects of the line. Infrared heating technology and convection offers precise temperature control for a consistent, high quality laminate. Lami-Pro is designed for minimal energy consumption, lowering production costs. Turnkey solutions are available with all supporting equipment such as PVB cutters, clean rooms and autoclaves.

Print this page