Features

Architectural design

Contracting

Amazing Glazing

We celebrate some of the stunning achievements in Canadian glass construction.

March 23, 2015 By Jack Kohane

Invisible hardware means no distractions from beautiful views of the St. Lawrence River or from the great performances going on inside. A slight angle on the glazing corners made it possible to support the panels’ weight without the use of a ledge on the patch fitting.

Invisible hardware means no distractions from beautiful views of the St. Lawrence River or from the great performances going on inside. A slight angle on the glazing corners made it possible to support the panels’ weight without the use of a ledge on the patch fitting. Sometimes we need to just sit back and appreciate the great industry we are in.

Sometimes we need to just sit back and appreciate the great industry we are in. What could be more satisfying than creating beautiful works of architecture that will serve their occupants well for decades to come? There are a lot of ways to make money in this world, but participating in building the public spaces we live in has to be one of the best. Especially when you get to specialize in a material as versatile, technologically advanced, popular and attractive as glass.

In this feature, we have tried to capture some of the joy of creating with glass – to bring out the views, the reflections, the clean lines and remarkable shapes that modern glass architecture can achieve. There is no doubt from looking at these innovative projects that Canadian glazing is right at the head of the world pack when it comes to imagination and technical expertise.

Triumphant performance

The Isabel Bader Centre for the Performing Arts – Kingston, Ont.

The glazing is a big part of what makes the Isabel Bader Centre for the Performing Arts so glorious. This world-class, $72 million, 80,000-square-foot (including a 566-seat performance hall) facility, known simply as “The Isabel,” opened its doors in 2014, purposed to provide Queen’s University in Kingston, Ont., with a state-of-the-art facility for community and student performances, education and training. Project architects, Ottawa-based N45 and Oslo’s internationally renowned Snøhetta, created the design locating the bulk of the new building within the campus courtyard ringed by a historic brewery and stable – and then incorporated them directly into the new facility. For the glazers on this project, the intention was to install a special low-iron tempered glass for clearer views of the lakeside vistas (the structural glazing in the atrium faces the St. Lawrence River). Lobby lighting is directed upwards and is reflected down off the steel and stretched vinyl ceiling, creating a soft light and preventing glare off the windows from obscuring the views.

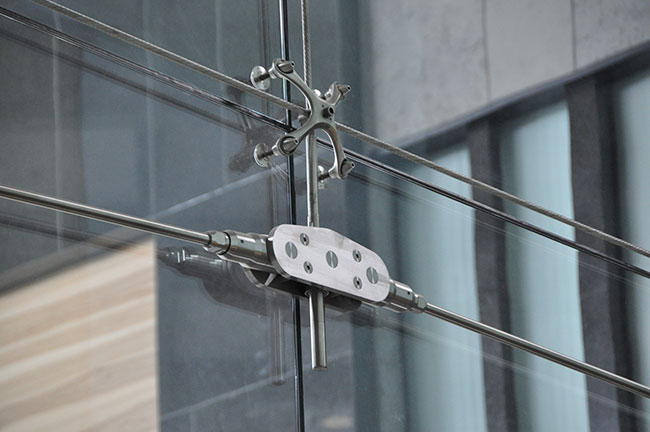

According to Tom Carolan, director of sales for Richmond, B.C.-based Stella Custom Glass Hardware, the main challenge was to install the glass using minimal hardware to support the glazing. “Typically on structural glass walls the access doors are required to have full portal frames, but there are three access doors on the Isabel that have stainless door headers supported by the structural glass fins,” Carolan explains. “Incorporating this detail with floor closers creates a transparent look.”

There are no holes in the glazing to support the face glass, and there is no “ledge” within the patch fittings in order to support the glazing above. Within the patch fitting is a diamond-shaped spacer, and the corners of the glazing are mitred. The weight of the glazing is not carried directly vertical. The corner of the structural glazing is at a 94-degree angle. By using patch fittings on this project, the corner fittings could be welded at the exact angle of the wall. Glass specs include glass fins of two-by-10 millimetre tempered laminate, 450 mm deep; the IGUs are 12 mm outboard lite, 12.7 mm airgap, 10 mm inboard lite. The wall is six metres tall at the highest. And the distance between glass fins is 1,226 mm. Quebec’s Prelco supplied the glass for this job. “Our aim was to create a structural wall that achieved the vision of N45 and Snøhetta with minimal visible hardware,” Carolan nods. Mission accomplished.

A good read

Halifax Public Library – Halifax, N.S.

|

|

| Glass supplier Prelco screened a leaf-shaped pattern in ceramic frit with random letters interspersed. Care was taken to make sure the letters didn’t spell anything untoward.

|

Sprawling across 120,000 square feet of space and trimmed with 66,000 square feet of glazing, Halifax’s new $57.6-million, five-storey gleaming glass library looks like a stack of books due to its unique cantilevered rectangular shape. Lauded as architecturally stunning and environmentally sustainable (it may achieve LEED Gold certification), with elegant angles and lines outside and winding stairs, study carousels, a 300-seat theatre and two cafés inside, the structure’s design was a collaborative effort between architects Fowler Bauld and Mitchell of Halifax, N.S., and Denmark’s Schmidt Hammer Lassen. “Many of the challenges faced on this project were related to the unique geometry of the building’s design,” says Andrew Suhayda, project manager for CGI Contract Glaziers, who partnered with Prelco Glass to provide the project’s glazing requirements. He points out that the building’s various intersecting planes created engineering hurdles in maintaining the building’s continuous primary seal between levels. “We held many design meetings to assure proper coordination of the structure, curtain wall and the roof/soffit scopes of work to guarantee the primary seal at the intersections were air/water tight,” he says. The library’s curtain wall uses the Schuco UCC 65 structurally glazed framing system.

The glazing specification for this project included a double-glazed insulated vision unit on the Level One podium, comprising an eight-millimetre low-iron, heat-strengthened glass lite with low-E on the #2 surface and tempered, six mm low-iron glass. Most of the structure’s upper levels were of custom-designed white leaf frit vision units and white leaf frit spandrel units alongside project-standard vision and spandrel units. Skylight glazing is an insulated vision/dot pattern skylight unit using a six mm clear, tempered glass lite with white ceramic frit 50 per cent coverage dots and low-E on the #2 surface, as well as 15.5 mm argon-filled with black spacer and silicone.

In addition to using conventional boom truck cranes, CGI used one of the company’s Jekko compact crawling cranes, the SPD265C Plus, for the majority of the installation of the curtain wall panels on the library project. “The Jekko mini-crane’s compact size gave us the ability to install efficiently while having increased mobility throughout the jobsite,” Suhayda comments.

The building also boasts a glass cantilevered “City Living Room” with panoramic views of Citadel Hill and the harbour located off the North Atlantic Ocean. “The goals of the project were to provide design/assist solutions for the high performance unitized façade… done,” Suhayda affirms.

New kid on the block

The Queen Richmond Centre – Toronto, Ont.

|

|

| Balanced on giant steel columns, the Queen Richmond Centre appears to float above a historic brick warehouse. Each steel support column is seven storeys tall.

|

Floating atop a preserved brick heritage building, the new 11-storey Queen Richmond Centre (or QRC West), is taking shape as the newest addition in Toronto’s entertainment district. The office tower, a proposed LEED Gold structure slated to open mid-2015, will stand above the restored four-storey historic warehouse – an architectural gem made visible from the outside thanks to a mast truss glass system.

“The project was a combination of new construction and replacement fenestration products for the restored buildings located at the site,” says Doug Lilja, sales manager for Ferguson-Neudorf Glass, the glazing contractors for this landmark building. “The historic restored building required the replacement of punched opening windows, some of which were curve tops and included casement windows.”

The Sweeny and Co. Architects and Stephenson Engineering-designed tower is supported by three seven-storey steel X-shaped column supports. The roof area is a training room that looks out on two sides at the Toronto skyline and the interior on two sides looks through a two-storey structural glass wall down into the atrium.

Some of the QRC West’s key features are the inclusion of functional 42-inch-deep horizontal sunshades which had five six-inch-long oval blades on the south elevation. The east and west elevations included an array of both 18- and 12-inch-deep functional vertical caps. Horizontally some areas included a custom four-inch-deep arrowhead shaped cap and either a glazed or a six-inch-deep bumped out metal panel at the spandrel areas. The west elevation also included a one-storey curtainwall fly-by at the roof area. The vision glass on the tower is Viracon VRE1-59 and the spandrel glass is Viracon VRE1-59 with V1086 simulated sandblast on the #3 surface.

The structural glass wall was tendered as an early award package to be supplied under a design/assist basis. The design/assist process investigated various glass fin and steel truss backup options, glass fitting designs and glass makeup and size options. The final design, Lilja notes, includes a center mast steel truss design that included stainless steel tensioned tie rods and clevises. The trusses reached a maximum height of 68 feet. “This span makes the QRCW project one of the tallest structural glass projects in North America, with a total square footage of glass of approximately 17,000 square feet,” Lilja says with pride.

Making the grade

Branksome Hall Athletics and Wellness Centre – Toronto, Ont.

|

|

| Stouffville Glass had to pull together an enormous amount of interior and exterior glazing in a short 12-month period to execute this intricate sports complex.

|

When Angelo Cairo thinks about the $1.8 million glass installation his company did for the intricate Branksome Hall sports complex project, he’s still amazed it all came together in just 12 months. There were some definite challenges to hurdle, notes the president of Stouffville Glass, a glazing firm north of Toronto. “This project was a nine out of 10 in difficulty level,” he stresses, pointing out that this glazing job was anything but typical. Five different types of glass were called for by the project’s architects, MacLennan Jaunkalns Miller, creating a supply and logistics tour de force in delivering each pane on site, on time.

The new 75,000-square-foot Branksome Hall Athletics and Wellness Centre, completed last year, is the centrepiece of the revitalization plan for this century-plus independent all-girls school sited on a 13-acre campus in the heart of Toronto. The facility includes a 25-metre indoor pool, gymnasium with viewing space for spectators, dance studio and cafeteria to accommodate 600 students.

“We used nearly every product here that Alumicor offers,” Cairo says. An array that included capped, two-sided and four-sided structural silicone with different interior and exterior colours and three different back member sizes coupled with skylight glazing, entrance framing, phantom doors and vents and non-thermally-broken interior aluminum framing. Stouffville Glass brought in Prelco using Cardinal’s low-E 272. Cairo asserts that the glazing for the project was one of the most difficult combinations for procurement and management “due to having different frit types on different elevations, which have match lines as they went across the elevation,” he says.

Each 600-pound pane of glass in the facility’s interior rooms was manoeuvred gently into place, in often very tight spaces, using a Winlet 1265 telescopic robot mini-manipulator. “Our employees were able to work more efficiently, avoiding back injuries and sick days,” Cairo claims.

Designed to meet LEED Silver certification, the Athletics and Wellness Centre uses a high performance glazing system as the glaziers used a utilized curtain wall at the exterior, primarily in a four-sided application to eliminate most of the exterior aluminum assemblies. Having large thermo-glass vision lights also contributed to the performance of the system. The exterior vents are all silicone glazed as are the doors, so exposed aluminum on the exterior has been eliminated again. “It was done this way because architects like to have clean lines and the assembly concealed,” Cairo says.

Cable net glass wall

Complexe Desjardins – Montreal, Que.

|

|

| CPA Structural Glass had to work backwards to arrive at the correct tensions that would achieve the geometry it needed to execute this suspended cable wall.

|

It was unconventional reverse engineering that garnered CPA Structural Glass the AVFQ’s 2014 Award of Excellence for “Innovative Project of the Year.” Presented with the challenge of conceiving a new glass wall of 60 by 60 feet to increase visibility and create a new entrance hall for the Montreal Head Office of Mouvement Desjardins, CPA crafted a self-contained cable wall designed to minimize loading transferred to the existing structure. Located in the Complexe Desjardins, comprising office towers and retail space covering two city blocks in downtown Montreal, the renovation project architects gave CPA (a division of engineering firm SDK Associates) carte blanche to come up with something unique.

“Adding 20 tons of glass and steel to an existing structure is far from simple,” CPA’s president Benoit Cloutier says. “But we came up with the idea of creating a perimeter frame to take the compression loads from the tensile system composed of catenaries and cables in both vertical and horizontal directions.”

The catenaries feature high strength stainless steel rods interconnected to nodes permitting the threaded swaged ends of the stainless steel cables to be anchored. “The main challenge was that we knew the final geometry that was needed for the placement of the cables and we performed reverse engineering to find the un-deformed geometry prior to tensioning,” explains Cloutier. Hundreds of simulations later, a solution was found: some cables were stretched more than five inches to achieve tensions varying from 7,500 to 12,000 pounds; the top catenary carries loads of 90,000 lbs.

Progressive installation of glass and deformations were closely monitored and compensated with pre-loading of the vertical system in order to achieve the final geometry. At each sequence, the support anchor points interconnecting the cables were added one level at a time, then the spiders and the glass. On the last pre-load release, a perfect equilibrium was reached with all the glass panels levelled. The glass (eight-millimetre clear heat strengthened; 1.52 mm SentryGlas; and eight mm clear heat strengthened supplied by Prelco) and glass hardware (SADEV S3000 Monti Spiders SS Type 316 brushed finish; SADEV V2001 countersunk fixed fitting supplied by CPA Structural Glass) were selected for strength and flexibility since the corner panels experience warping due to the deflected shape of the cable net.

“Our proposal exceeded by far their initial vision of what the wall could be,” boasts Benoit, who received the Excellence Award from the Quebec glazing association.

Eden of Vancouver

Boedel Conservatory – Vancouver, B.C.

by Rich Porayko

|

|

| Challenge: replace 1,488 acrylic panels without letting the tropical plants and birds on the other side get cold. And improve the thermal performance of the 45-year-old structure so the city can still afford to heat it. Photo by Rich Porayko |

Five years ago the City of Vancouver issued the Bloedel Conservatory a death sentence and ordered the building to be shut down. But the dome, located in Vancouver’s Queen Elizabeth Park, was home to 500 plants and 170 species of birds. So, concerned community and business leaders weren’t willing to let the ecosystem, which has been called a “horticultural, architectural, natural, green jewel at the pinnacle of Vancouver” die. They started the Friends of Bloedel Conservatory and not only successfully lobbied the city for a stay of execution, but also secured funding to rehabilitate the aging façade of the 45-year-old landmark. Bloedel is very much alive and thriving today thanks to their efforts and to Spectrum Skyworks, the company tasked with completing the job.

“The biggest challenge we had was at the beginning,” Spectrum’s managing partner Ken Boyce said. “The company that built the dome back in 1969 only constructed one other like it, so there was nothing to explain how Bloedel was going to be rehabilitated. We had to figure it out.”

Spectrum was familiar with the structure because it had been repairing the dome’s panels for up to 12 years before the decision was made to do a full-scale rehabilitation. “The panels would break because teens used to climb on them at night,” Boyce said. “Replacing one panel is a big deal. You need a lot of people. But nobody had ever taken the whole building apart.”

The Bloedel Conservatory is a geodesic dome that consists of 1,488 quarter-inch-thick, acrylic panels in 32 different sizes. Spectrum installed thermal breaks into all 866 of the original cast hubs, which were then reused. Dayliter Skylights, a division of Spectrum based in Langley, B.C., has its own thermal formers. So Spectrum was able to manage the supply chain and blow the dome panels itself.

Spectrum removed up to 30 old domes and asbestos and then installed 30 new domes in one 10-hour shift every day. Once each panel was installed, it had to be face sealed. To allow for the thermal expansion/contraction of the acrylic, Spectrum had Tremco – a supplier of sealant, weatherproofing and passive fire control solutions – design special gaskets to fit into the existing extrusions and also to achieve improved thermal performance of the overall system.

Safety was Spectrum’s primary concern throughout the entire project and because Bloedel had low-grade asbestos in the old mastic, it had to take special measures. “First thing each morning, we’d suit up three guys in their Hazmat suits with full respirators and we’d do a clean with special vacuums approved for asbestos removal,” Boyce said. “We hired Proactive Hazmat and Environmental Ltd. to oversee everything and take away the waste material every day.”

Print this page