Features

Community

Under the Glass

Going south in a good way

Border Glass finds Canadian glazing practices export well.

February 7, 2014 By Rich Porayko

Celebrating 47 years of in the glass industry, Border Glass is proud to be a successful, third-generation family-owned business.

Celebrating 47 years of in the glass industry, Border Glass is proud to be a successful, third-generation family-owned business. Correction, a successful, third-generation, professionally managed family-owned business.

|

|

| Alex Gluskin programs the automated CNC multi-tool workstation. Border Glass has invested in staying on pace with the much larger competitors. Photo credit: Anna Borys

|

Originally founded in 1967 in Selkirk, Man., by Don Borys, a long-respected member of the Manitoba glass and aluminum community, Border Glass is now owned by Don’s sons David and Paul, who have relocated and expanded operations with offices and manufacturing facilities in Winnipeg and Phoenix, Ariz.

|

Year established: 1967

Number of employees: 80 Location: Winnipeg, Man., and Phoenix, Ariz. Facility: 37,000 square feet Products: Installed curtain wall and commercial storefront Main markets: Manitoba, Saskatchewan, Alberta and Arizona |

“We’re a professionally managed, family owned business,” says Paul Borys, president, CEO and co-owner of Border Glass. “Ten years ago, as we were looking to a young third generation coming on board, we felt the need to bring on a group of skilled management professionals and I believe we have succeeded in building a very solid team. They are virtually running the company now, and that’s very gratifying considering how much we’ve invested into our people.”

“We have approximately 75 employees,” says co-owner and director of sales David Borys. “Our biggest and most important asset are our people. The culture of family permeates everything we do. I do not get tired of saying that, because it’s a fact. We have second- and some third-generation employees. We often have employees bringing their kids and/or nephews here because it’s a great place to work. That’s what we’re all about.”

“All three of my kids, and two of Paul’s kids work for Border Glass in very responsible roles,” says David. “Our brother Tim is Border’s director of production. We have a lot of excellent people here that do a very good job for us.”

Border Glass serves low- to medium-rise curtain wall customers across western Canada but primarily in Manitoba and Alberta. The company boasts a long list of flagship projects including malls, office buildings, arenas and airports. Some of the projects Border Glass has completed include MTS Centre (home of the Winnipeg Jets), the Manitoba Remand Centre, the Winnipeg Police Services building, the University College of the North (UCN) located in northern Manitoba and the interior portion of the “double skin envelope” of the Manitoba Hydro Building. Border is wrapping up the interior portion of the Canadian Museum of Human Rights and is currently working on Heritage Landing on the Assiniboine river which is a 28-storey, $70,000,000 tower. The company is also installing the curtain wall for the podium at the mixed-use, 200,000-square-foot Centrepoint in downtown Winnipeg which includes residences, a boutique hotel, two restaurants and offices.

“For a big project, we might see competition from Toronto and Vancouver,” says David, “but Winnipeg is, relatively speaking, not that big of a city. It’s not that attractive a market for them. The true high rise towers don’t exist here. The tallest are typically 30 floors and we’ve been in Manitoba for 47 years which makes it a challenge for out-of-town competitors to compete for the bigger jobs.”

According to David, Border Glass has grown where it can easily handle anything in Winnipeg, however they also reach out into Saskatchewan, Alberta and even south of the border as well.

“We’ve been in the United States for 12 years now, primarily in Arizona, however we’ve completed projects in Washington and North Dakota as well,” says Paul, who lives and works out of the company’s Phoenix location. Paul frequently travels to Canada fulfilling his role on both sides of the border.

|

|

| Some examples of Border Glass’ work. Top right is the Optical Science Building at the University of Arizona and bottom is the MTS Centre in Winnipeg, home of the Winnipeg Jets. Border Glass has found its familiarity with high thermal specifications has given it an advantage in the southern U.S. Photo credits: Anna Borys

|

“We were met with open arms in Arizona,” says Paul. “Contractors and developers saw how we performed in the first few years and our reputation and business grew by word of mouth from there. In Canada, the building codes are based mainly on thermal performance, debatably more so than air and water, and we brought that standard of performance to the southern U.S. Heating isn’t much of a concern in the Phoenix area but energy costs for cooling are an issue so the thermal performance of our walls in the U.S. is an important consideration.”

“Our approach is to focus on quality but at the same time get jobs closed in as quickly as possible. Much of our product is installed outside and for half the year our northern crews work in a very harsh climate. For that reason alone it seems we were geared for a better timeline on large projects than our local competitors in the U.S.”

“The trend is very much towards energy efficiency,” says David. “We often help out at the design stage of projects, which includes performance reviews, cost budgeting, and providing advice for systems or details. We make ourselves available to owners, architects, and engineers to provide this service.”

David continues, “The need is usually made up of three components: performance, price and delivery. We tailor-make our product and service to fit the job. If we only have three months to install it, we need to look at the supplier and the system. If there is a need for high performance, for instance a swimming pool or a tightly controlled environment, then we work with the designers to make sure the system is appropriate. If there are significant budget concerns, we can look at considering alternative suppliers.”

“We know most of the architects very well,” says David. “They will call us in and might have a partial idea of a glazing system, but a clear vision of what they are looking for and we’ll say ‘tell us what you want to do.’ We will work with whatever product and/or supplier necessary to get the right solution. If necessary, we’ll cut our own dies and do what we have to do.”

|

|

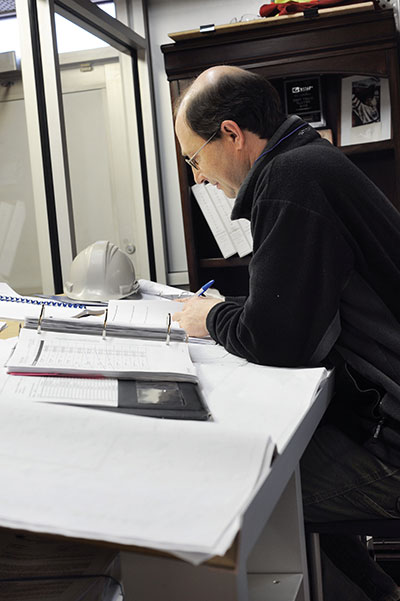

| Ryan Trombo, Border Glass production manager, reviews drawings for a current project.

|

There has always been a demand in Canada and the U.S. for security glazing in institutions such as penitentiaries, courthouses and detention centres which have high-end requirements on the interior. “We are very fortunate to have projects such as the Winnipeg Remand Centre and Sherriff Joe Arpaio’s new home in Arizona as a significant part of our portfolio,” shares Paul. “When we perform on the building envelope of a jail or a courthouse, we generally do all of the security glazing within. On the U.S. side, Homeland Security since 9-11 has imposed demanding design requirements on our industry, such as blast mitigation. There are some good specialty glazing opportunities available for glazing contractors in Canada and the U.S. who want to expand outside the building envelope.”

Five years ago the economy crashed and the American division of Border Glass went into survival mode to pull through the tough times. “Several of our competitors are gone now and we are perfectly positioned to take advantage of the sleeping giant awakening,” says Paul. “And not just Arizona; we see signs of the entire U.S. coming back to life. We have invested a lot in maintaining a presence as well as staying on pace with the much larger competitors. We’re looking to expand our market size and volume in the U.S. in the next several years.”

|

|

| Border’s philosophy is to do what you have to do in order to find the right solution. All aspects of a project are considered and tailored to the customer’s needs. Photo credits: Anna Borys

|

“Border Glass as a whole has thrived in the last six or eight years largely due to the high standard and work ethic of our people” states Paul. “We’ve created a culture and working environment that good people want to be a part of. If you talk to the CEO of any successful company, they are going to tell you that a key to successful growth is to get the right people in the right seats. My job for the last eight years has been largely focused on accomplishing that. We have very little turnover in our company. There must be something about the way we treat our employees right from the day they arrive and lately we don’t spend a lot of money on help wanted ads.”

“We’re like a breath of fresh air when it comes to employers in the Phoenix market,” says Paul. “We don’t lay off very easily. If we find good people, we try to keep them busy. We paid for everyone to stay at home over Christmas. You have to spend money to make money and we’ve found that ‘our people’ is a very good place to invest. That’s been a win-win for many years now. We’re happy with the profitability and David and I hear from folks on a regular basis that Border Glass is a great place to work. That to me, is a big part of being successful in business.”

Rich Porayko is a professional writer and founding partner of Construction Creative, a marketing and communications company located in Metro Vancouver, B.C. richp@constructioncreative.com

Print this page

Leave a Reply