Aug. 23, 2010 – Sono-Tek Corporation has announced it will be showcasing its precision ultrasonic atomization technology at Glasstec 2010 in Hall 12, booth B64 on September 28th – October 1st in Dusseldorf, Germany. Sono-Tek provides ultrasonic coating systems for depositing drip-free uniform nanolayers of solution onto float glass, architectural glass, solar glass, mirrors and other specialty and functional glass products.

Aug. 23, 2010 – Sono-Tek Corporation has announced it will be showcasing its precision ultrasonic atomization technology at Glasstec 2010 in Hall 12, booth B64 on September 28th – October 1st in Dusseldorf, Germany. Sono-Tek provides ultrasonic coating systems for depositing drip-free uniform nanolayers of solution onto float glass, architectural glass, solar glass, mirrors and other specialty and functional glass products.

|

|

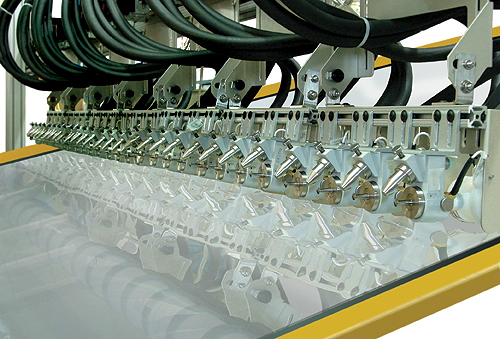

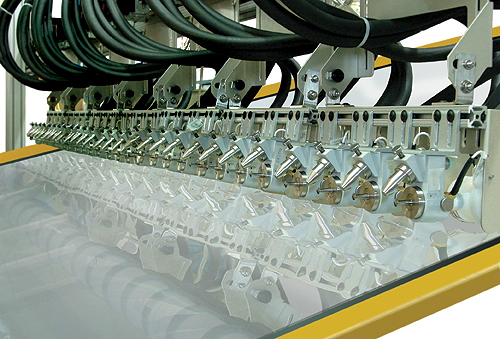

| Sono-Tek says its WideTrack system (shown above) is ideal for applying protective polymer solutions onto low-e glass. |

Aug. 23, 2010 – Sono-Tek Corporation has announced it will be showcasing its precision ultrasonic atomization technology at Glasstec 2010 in Hall 12, booth B64 on September 28th – October 1st in Dusseldorf, Germany. Sono-Tek provides ultrasonic coating systems for depositing drip-free uniform nanolayers of solution onto float glass, architectural glass, solar glass, mirrors and other specialty and functional glass products.

According to the company, important advantages of ultrasonic atomization versus pressure nozzle systems include savings of up to 80 percent in coating material with virtually no overspray, no dripping, no bounceback, and no clogging. Sono-Tek says its WideTrack system is ideal for applying protective polymer solutions onto low-e glass. The system has many integrated features such as: no heat build-up despite the high temperatures associated with float glass production, state-of-the-art pump control system that delivers repeatable flow to each nozzle, integrated air conditioning system that keeps electronics cooled, control tower with real time monitoring and PLC control of all system functions via HMI interface, line speed encoder for continuous process monitoring, and on-the-fly optimization. Individual nozzle triggering allows custom configuration of spray for different width lites.

Other glass coating applications include anti-reflection / anti-glare, anti-stain, anti-static, photoresist, self-cleaning (nanophase), touch screen (CNTs), solar cell compounds, and other active/passive coatings. Multiple nozzles are configured for coating any width glass.

The core of Sono-Tek’s coating equipment is its non-clogging ultrasonic atomizing nozzle. Using high frequency vibrations, the nozzles create a soft, low velocity spray that readily adheres to glass surfaces without any bounceback of material into the atmosphere . Ultrasonic nozzles are highly efficient, dramatically reducing or even eliminating the need for exhaust requirements and expensive scrubbing systems. An additional unique feature of all Sono-Tek’s ultrasonic coating systems is the deagglomeration of particles in suspension during the coating process. This can be particularly valuable in the deposition of CNTs and other nanosuspensions that are notorious for agglomerating. The ultrasonic vibration of the nozzle provides this inherent benefit.

For more information, please visit www.sono-tek.com .

Print this page

Leave a Reply