Features

Energy efficiency

Fabrication

The condensation equation – Studies reveal the impact of spacer technology on condensation performance

A new study takes a look at the effects of spacers on condensation in Canadian climate conditions.

March 3, 2021 By Emu Systems for Swisspacer

If there’s going to be a condensation problem in a building interior, it will show up at the glass edge first. Ironically, today’s airtight builds can make the problem worse. Photo: Getty Images/Akchamczuk

If there’s going to be a condensation problem in a building interior, it will show up at the glass edge first. Ironically, today’s airtight builds can make the problem worse. Photo: Getty Images/Akchamczuk The thermal quality of glass spacers dramatically affect the physical properties of one of the most critical areas of the entire building thermal envelope – the interface between window frame and glass unit. The spacers influence the heat flow, resulting in higher heat losses and consequently lower localized temperatures along the glass edge.

The glass edge is one of the places condensation occurs sooner than anywhere else in a building. Since its 2012 update, the International Energy Conservation Code (IECC) has been pushing buildings to be increasingly more airtight across America. This is great news for overall building durability through avoidance of exfiltration and associated moisture-driven damages. Increased building air tightness also leads to significant improvements in energy efficiency, thanks to the reduction in heating and cooling.

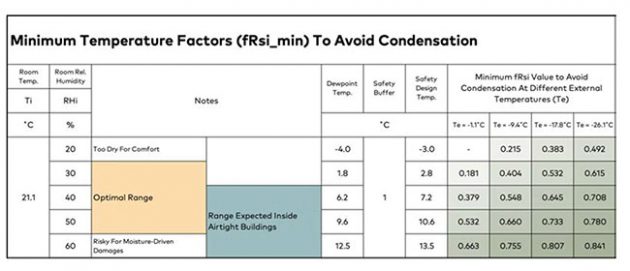

However, a more airtight building envelope leads to higher relative humidity inside buildings as uncontrolled air leaks contribute to removing moisture water vapour from inside buildings. According to ASHRAE Standard 160, a family of four produces 2.5 gallons of water vapour every single day. This means that regardless of how humid or dry a climate may be, moisture comes from within the building.

Proper moisture management in buildings has evolved into an interdisciplinary field, bridging architectural detailing, window specifications and structural and mechanical engineering. The more buildings become airtight and insulated, the more they behave as one physical object where all parts are interrelated. Today, the selection of a window product (including glass spacers) has consequences on the mechanical system in the effort to avoid mould/ condensation, and vice versa.

Unfortunately, the evolution of building standards (until the 2018 IECC update, at least) has still failed to mandate this interdisciplinary approach, resulting in manufacturers and professionals being incrementally more exposed to liability. Even the condensation resistance method established by the National Fenestration Rating Council does not provide a conclusive method to prevent condensation in fenestration products.

Given these circumstances, the impact of different glass spacers on the performance of window products is assessed both in terms of heat flow (U-factors), as well as of surface temperatures to avoid condensation.

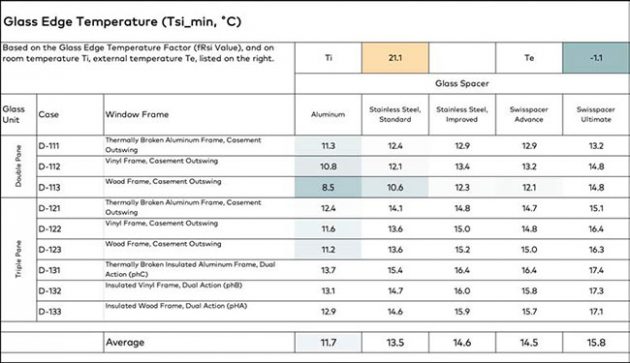

The study conducted by Swisspacer was executed by creating combinations of five glass spacer products and nine window frame profiles. The 45 resulting combinations were evaluated in terms of localized heat flow (frame and edge-of-glass U-factors), whole-window heat losses (total U-factor) and glass edge temperatures.

The condensation resistance (CR) method defined by NFRC assigns a score to the fenestration product. This is executed by averaging internal surface temperatures resulting from three separate simulations (that is, at 30, 50 and 70 percent relative humidity).

The purpose of the CR score is to allow different products to be compared to one another, not to assess the actual risk of condensation on one specific product as part of the design process.

Due to its mathematical nature, the CR score does not represent a tool to be used in professional practice, in combination with other design parameters.

For this reason, for the purpose of calculating localized internal temperatures on the glass edge with the goal to avoid condensation, this report refers to the temperature factor’ method (fRsi value) as described in ISO 13788.

fRsi = ( Tsi_min – Te ) / ( Ti – Te )

- fRsi: temperature factor

- Ti: room temperature

- Te: external temperature

- Tsi: minimum localized lowest temperature on the model considered

Once the fRsi value is calculated with the finite element method, the localized lowest temperature on the internal surface can be calculated by reversing the above formula as: Tsi_min = Te + fRsi * ( Ti – Te )

Nine different window frame profiles were selected as part of this study, with the intention to cover a range of frame types, materials, operation, glass units, and overall energy performance. While the list of frames included does not cover all options available on the Canadian market, it can be considered to be significantly representative for the scope of this report. Five types of glass spacers were used in the modeling, in order to provide a wide enough range of performance for the analysis. For greater accuracy, the spacers were modeled according to their actual materials and geometry rather than using the two-box model. Two types of insulated glass units were considered for the modeling. All glass units were modeled sealed with hot melt butyl.

Risk of condensation

Condensation occurs as a combination of localized low temperatures (Tsi_min), and relative humidity inside the building (RHi). NFRC condensation resistance is purely an averaged score over multiple data points, and it is designed to allow comparisons between different window products. However, it is not of use when trying to assess the risk of condensation on one specific product.

The ISO 13788 temperature factor method is designed specifically to estimate the risk of condensation on the internal surface of building components, including fenestration products. The localized lowest localized temperature (Tsi_min) on the internal surface of the combination of window frame/glass unit/ glass spacer is calculated with formula 04, based on the fRsi value, and the internal/external temperatures Ti, Te.

The temperature factor described in ISO 13788 is the same as illustrated in CSA A440.2, with the only difference being that the CSA method relies on testing on a physical specimen instead of FEM modeling.

Conclusions

The Canadian construction industry is undergoing significant changes in terms of how quality is measured in buildings, and the expectations and liability that come with it.

Energy codes now require buildings to be airtight, yet they still fail in thoroughly addressing the consequences associated with this practice in terms of building science and proper moisture management. Design teams often still limit their work to traditional siloed scopes, without realizing how interrelated different portions of the building have become. For example, specifying a traditional aluminum glass spacer now has consequences on the building moisture management, and impacts other scopes of the design (e.g. the mechanical system). This increase in risk of moisture-driven damages is still largely unknown to many Canadian architectural glass professionals.

The purpose of this report was to assess the impact of different glass spacers on the performance of Canadian fenestration products. The evaluation covered both energy performance, and avoidance of moisture-driven damages.

Improvements were noted on the whole-window U-factors provided by using better glass spacers. Compared to the baseline of aluminum spacers, the use of warm edge spacers such as Swisspacer Ultimate allows reductions in heat losses by up to over 22 percent and about 16 percent in average across all window products considered. Improvement of the window energy rating was also evident for residential use, depending on the type of glass spacer used.

However, the critical advantage of using warm edge glass spacers lay in the higher glass edge temperatures resulting from the heat loss reduction. Warm edge spacers provided considerably higher glass edge temperatures compared to the aluminum spacer baseline: from 4.1C temperature difference at -1.1C external temperature, to 8.7C temperature difference at -26.1C external temperature.

With buildings becoming more airtight and closer to zero energy consumption, accurate detailing and selection of climate-suitable components become critical steps towards ensuring project success. The results of the analysis summarized in this report clearly show how much of a difference warm edge glass spacers can make both in terms of energy efficiency, and prevention of condensation. •

This paper was prepared by Emu Systems for Swisspacer. A section of the paper has been reprinted here with permission from Swisspacer.

Print this page

Leave a Reply