The Erdman 400 Series spacer applicator introduces a new level of automation to the insulating glass industry.

|

|

Simple design

www.erdmanautomation.com

The Erdman 400 Series spacer applicator introduces a new level of automation to the insulating glass industry. This low-cost insulating glass production system works with all flexible spacer systems applying the spacer straight with true 90-degree corners. Minimal operator training and no data input are required for standard operation. The innovative yet simple design allows a significant cost savings over other automated spacer application systems. Low skill-level personnel can produce high quality IGU’s consistently. IGU quality is improved through consistent spacer offsetting from the edge of the glass, which in turn guarantees the desired amount of secondary sealant is applied. Operator fatigue and repetitive motion injuries are reduced. The 400 Series increases productivity with a consistently quick cycle time. Spacer waste is significantly reduced compared to typical manual application. Operators have the option to provide accurate grid placement by slicing the spacer prior to application.

|

|

Better sightline temperatures

www.fenzi-na.com

Fenzi North America has added to its product base with the addition of the Chromatech and Chromatech Ultra Stainless Steel warm edge spacers. Manufactured by Roll Tech, a Fenzi owned company, these spacers are available with corner keys and connectors for those wishing to bend on bending equipment. Addressing the ever-changing need to meet more stringent energy codes, the Chromatech line of stainless spacers delivers better sightline temperatures in excess of 17 per cent when compared to traditional aluminum. Both Chromatech and Chromatech Ultra spacer’s are available in a wide range of air space widths. The Chromatech Ultra has a polycarbonate bridge across the top, available in traditional white, grey and black colors. Combined with our Fenzi Hotver 2000 Hot Melt Butyl, Fenzi Thiover Polysulphide, Fenzi Molver 3A Desiccant, Fenzi Butylver PIB and Alu Pro aluminum spacer profiles, Fenzi North America continues to be a single source supplier for all IG component needs.

|

|

Artistic expressions

viracon.com

DigitalDistinctions is a digital printing solution that enables building designers to insert their artistic expressions into a glass façade. Combining the durability of ceramic inks with the versatility of digital printing, DigitalDistinctions provides one proven solution for all glass-printing applications. It enables a vast selection of colours to be applied to a single lite of glass, and is highly customizable to high-resolution images, patterns, text, textures, dots and lines – just to name a few. DigitalDistinctions offers supreme predictability, repeatability and ceramic ink durability, with the added benefits of UV resistance, transparency and scratch resistance. In addition, Viracon’s solar control coatings can be applied directly over the digital image – a turnkey competency for which Viracon is well known. In terms of overall building performance, DigitalDistinctions enhances the functionality of glass by optimizing light diffusion and transmission, energy efficiency, solar control and the support of carbon emission reduction. DigitalDistinctions offers the unique ability to customize individual glass lites, each with its own design, colour scheme and ability to fit a variety of glass systems. It can be combined with clear or tinted glass substrates as well as with high-performance coatings. Similar to its continuing silk-screen technology, Viracon can provide customized, distinct imagery and the essential solar control performance on the most appropriate glass surface.

|

|

The need for speed

bystronicglass.com

Bystronic glass offers its SpeedLine automatic spacer application line which is able to produce triple insulating glass in the same time it takes other lines to produce double units. On the SpeedLine, the fully automated application of the spacers can be performed by two TPS applicator components arranged one after the other. In order to achieve the maximum throughput, the thermoplastic TPS warm edge spacers are applied almost simultaneously. This permits a real, order-based production without any time losses, without having to divide the orders into standard and special formats or subsequently sorting the units. The quick-assembling, gas-filling and pressing of triple IG units is performed by the SpeedAssembler. It is the first unit to simultaneously fill both of the spaces between the lites of triple units with inert gas. This is beneficial to the cycle time as it reduces the filling time for each unit by half. The SpeedSealer makes the quick and flexible sealing of triple insulating glass units in two cycles possible in the last stage of IG production. This ensures that no equipping times are required to exchange nozzles, even when producing units with alternating or asymmetric spaces between the lites. The core of the SpeedSealer is its dynamic mixer. It works with a significantly reduced material pressure compared to a static version. With a flow rate of up to six litres per minute, it also makes the utmost material volume available.

|

|

Superior condensation control

crlaurence.com

CRL’s Edgetech Super Spacer is crafted from superior quality insulating silicone foam (used in place of traditional metal spacers) that substantially reduces overall window heat loss and eliminates perimeter edge condensation. It is designed for use with both ordinary and unique insulating glass applications, including sound insulating units, curved and oddly-shaped units, and triple glazed units with art glass inserts. The Edgetech Super Spacer’s silicone foam construction reduces thermal conductivity at the insulating glass unit edge. The spacer essentially eliminates perimeter edge condensation because the silicone foam contains its own high quality low-deflection molecular sieve desiccant. The permeability of the foam allows for fast moisture pick-up. To reduce moisture vapor and gas transmission, the silicone spacer is backed by a high-performance, multi-layer barrier film. CRL’s Edgetech Super Spacer is available in a 66-foot-long roll and comes in various widths from 3/16 to 3/4 inch. Standard colours are black and gray, with custom colours available on special order.

|

|

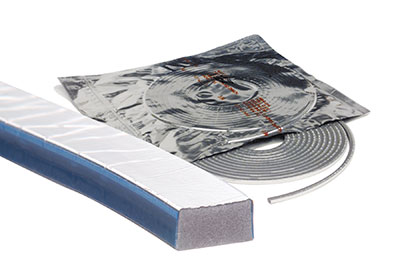

Beats metal-based systems

quanex.com/architect

Super Spacer TriSeal from Quanex Building Products is a flexible, silicone foam spacer with a unique triple seal designed to satisfy the toughest commercial glazing demands, including silicone structural glazing. With its shock absorbing tendencies and a robust construction, Super Spacer TriSeal is an energy-efficient solution that compensates for common glazing stresses found in the extreme Canadian climate, including high wind loads, snow loads, driving rain and widely fluctuating temperatures and barometric pressures. Because of its resiliency, Super Spacer TriSeal is proven to dramatically reduce stress cracks and premature seal failure over metal-based systems. IGU manufacturers can achieve the best in aesthetics, energy efficiency, strength and durability in architectural glazing projects with the Super Spacer TriSeal warm edge spacer system.

|

|

Improved quality and consistency

erdmanautomation.com

The Erdman Fixed Head IG Secondary Sealer is a simple and economical answer to your insulating glass secondary sealing needs. The stationary sealant application system gives your operator the ability to easily apply a professional, high quality, consistent secondary seal to your insulating glass units. The Erdman Secondary Sealer can deliver cycle times up to 50 per cent faster than hand gunning, even without including time saved on scraping and clean-up. The total quality and consistency of your seals will be improved. All four corners can be completely packed. The Erdman Secondary Sealer can be justified by reductions in over-fill, excess purging, IG clean-up and eliminated under-fill. The quality of the seal achieved rivals expensive, fully automated machines. The Sealer can be configured for dual- and triple-pane units in one pass. Special shapes can be precisely sealed with no program change.

Print this page

Leave a Reply