News

Spandrel help

Spandrel efficiency solved with B.C. brainpower.

November 29, 2017 By Patrick Flannery

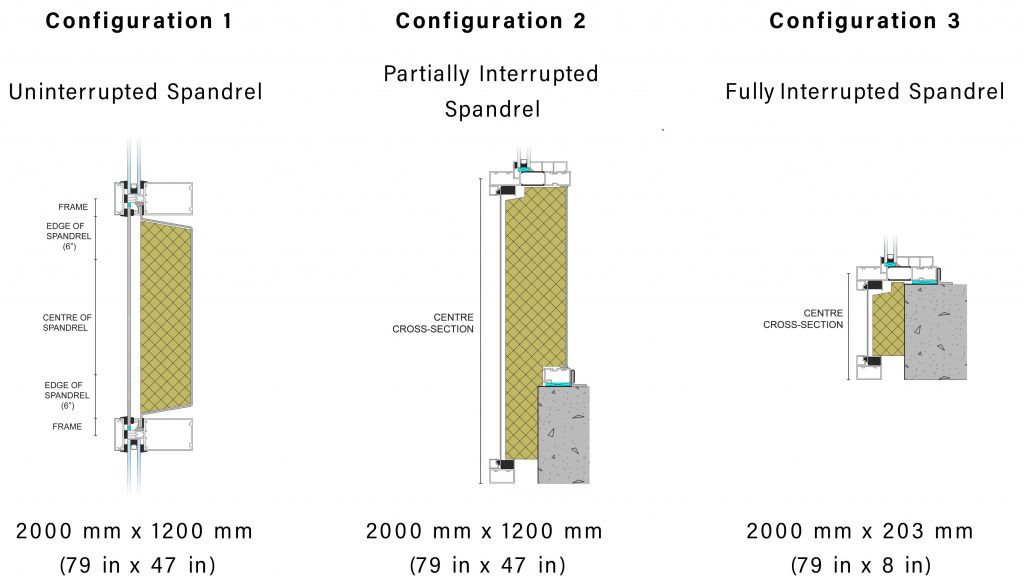

Different spandrel configurations can have widely varying energy performance. According to RDH research, uninterrupted spandrel provides about an R8 insulating factor, partially interrupted spandrel comes in around R4 and fully interrupted spandrel is closer to R2.

Different spandrel configurations can have widely varying energy performance. According to RDH research, uninterrupted spandrel provides about an R8 insulating factor, partially interrupted spandrel comes in around R4 and fully interrupted spandrel is closer to R2. The Fenestration Association of B.C., with the support of B.C. Housing, has taken a proactive step to advance the state of the industry by creating a new public resource, a voluntary “Reference Procedure for Simulating Spandrel U-factors.”

The procedure, developed with the assistance of RDH Building Science, supplements the methodology in NFRC 100 to help fenestration manufacturers determine more realistic spandrel panel U-factors for use with whole-building energy standards such as ASHRAE 90.1 and the Canadian National Energy Code for Buildings (NECB). The reference procedure, user guide and calculation tool are available as a free download from the FenBC website at fen-bc.org.

The need for a standardized procedure arose from FenBC member companies,” explains Al Jaugelis, RDH project manager. “We were getting calls asking for advice in dealing with spandrel conditions that differed substantially from the one in NFRC 100.”

“Having procedures like this is going to be more important as energy codes move towards energy modeling and performance-based metrics for energy code compliance across the country,” says Daniel Haaland, a building science engineer-in-training at RDH and a co-author of the procedure. “Building designers require accurate thermal performance data at the earliest stages of design. However, obtaining this information can be challenging. The objective for developing this procedure is to address gaps in the existing methodologies and provide project teams with more accurate effective spandrel U-factors. Use of a reference procedure allows performance claims to be compared more effectively than is the case today.”

The two main differences between the existing NFRC 100 methodology and the new reference procedure are:

- The reference procedure increases the edge-of-panel distance from the 2.5 inches used for transparent glass to 6 inches, a dimension found to more accurately capture the two-dimensional heat flow through spandrels.

- The reference procedure offers three spandrel product configurations, one of which is identical to the curtain wall configuration in NFRC 100. [See diagram.]

NFRC has recognized the need to update the spandrel modeling approach, and while detailed guidance is not presently available, they have initiated a Spandrel Validation

Task Group.

Print this page

Leave a Reply