Technology

Hardware & glazing systems

Product Showcase: February 2012

Curtain wall

February 13, 2012 By Glass Canada

Sika Canada has introduced new additions to its sealing and bonding line

for the fenestration industry, the Sikasil line of specialty silicones.

|

|

Specialty silicone

www.sika.com

Sika Canada has introduced new additions to its sealing and bonding line for the fenestration industry, the Sikasil line of specialty silicones. Designed specifically as high-performance sealants and adhesives for structural glazing, weather- and joint-sealing, insulating glass and a variety of other specialty applications, Sikasil silicones are designed to be used on a host of manufacturing materials. These silicones, manufactured to exacting standards, are gaining wide acceptance for their ease of use, their fast-curing properties, the strong bonds they create and their permanent elasticity.

- The professional-grade products in the line include:

- SG-10, a fast-curing, non-sag, medium-modulus, elasto-

- meric, neutral-cure sealant

- WS 290 and WS-290 FPS, pre-tinted or site-tintable, ultra-low modulus, neutral-cure and no-bleed sealant for weather sealing

- WS-295 and WS-295 FPS, pre-tinted or site-tintable structural glazing-/weather seal-grade, neutral-cure, no bleed sealants

- Sikaglaze IG-4429 HM, Heat-Mirror Insulating Glass sealant

- IG-25 HM, high-modulus sealant for air- and gas-filled insulating glass.

|

|

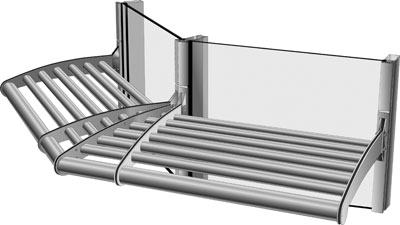

Enclosed glass truck body

www.myglasstruck.com

MyGlassTruck.com has announced the release of its new Hero, a distinctive, enclosed, glass carrier truck body that is available in 12-, 14- and 16-foot lengths. Engineered for maximum strength and minimal weight, Hero offers superior fuel economy and more payload capacity than bodies constructed of heavier materials riding on the same chassis. Hero’s efficient design uses strong, T6 aluminum, glass racks as part of a robust frame that supports the body’s .060 aluminum wall panels. A welcome alternative to cramped interiors, Hero has more work and cargo space than commercial vans. And, unlike open truck bodies, the Hero’s spacious interior provides protection from the elements and lockable security.

Standard equipment on each side of the Hero body includes full glass rack coverage, and floor-to-ceiling racks can be installed into both sides of the interior. The racks are fabricated from strong, 1/8-inch thick, 6061 T6 aluminum posts and slats joined together with aircraft-grade Huck fasteners that will not crack like welds on aluminum or loosen from vibration like screws or bolts.

MyGlassTruck.com racks provide excellent glass protection with rubber padding integrated along the full length of all posts and slats. The glass support ledge at the bottom of the rack is a fully usable five inches deep to accommodate thicker payloads and padded with thick rubber blocks.

A translucent roof lets the light in for visibility during loading and the floor has a non-slip surface for traction. The body uses a full LED lighting system with sealed wire harnesses and reflective tape at strategic locations around the bottom ledge. Easily removable skirts provide access to the rear wheels for simplified tire changes and maintenance. Lockable, double rear doors with anti-rack hardware offer a wide opening for loading and the cargo bay may be accessed via a rear step-bumper and two stainless steel fold-down steps and/or an optional roll-out walk ramp that self-stores beneath the floor. Other “off-the-shelf” options include sign panels with graphics as well as storage and toolboxes.

For securing glass to the racks, Hero comes with extra-tall, T6 Adjust-A-Poles featuring rubber triangle cleats that can be adjusted forward, backward, and to any position along the shaft.

Options include the premium, T6 Super-Pole with the precision adjustability and tension control of scissor-style cleats, and the E-track cargo control system.

All MyGlassTruck.com bodies are designed using an in-house, 3D, AutoCAD system and custom modifications are available. MGT works with all major truck dealers and leasing companies in the United States and Canada and is a member of the National Glass Association and the National Truck Equipment Association.

|

|

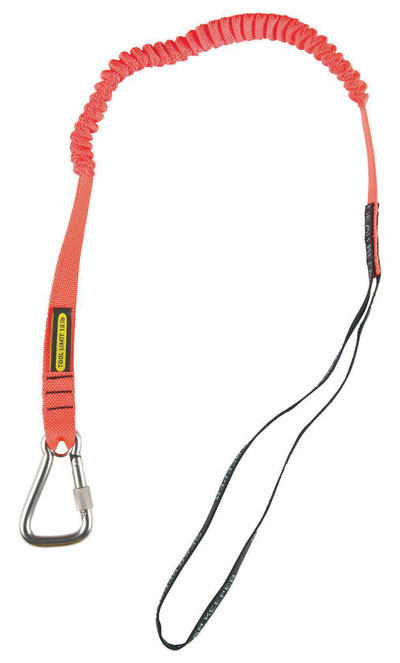

Easily attached tool tethers

www.gearkeeper.com

Hammerhead Industries, manufacturers of Gear Keeper industrial tool tethering systems, has announced a pair of new tool tethers for heavy tools and instruments. Both new anchored tethers are designed for attachment to a fixed structure rather than to a person.

The TL1-3025 Fixed Loop Tether and TL1-4025 Fixed Loop Tether are rated at 15 and 25 pounds respectively to keep drills, power drivers, electronic meters and other heavy tools and instruments safely tethered to avoid injury to the worker or the work site.

The fixed loop attachment feature of these new models also permits tethering of tools that have no other attachment point. For example, when a larger loop is required to go around a large handle (for instance, on a chain saw), the worker would just slip-knot the fixed loop over the handle.

Easily attached to a fixed object such as a high-rise bucket or scaffolding, the anchored tether transfers the shock load produced by a dropped tool from the worker to the structure. Tethering heavy tools over 10 pounds is a significant safety concern. If dropped, a 10-pound tool can have a shock load that exceeds 200 pounds.

The Gear Keeper model TL1-3025 Fixed Loop Tether has a short retracted length of only 32 inches to avoid entanglement coupled with a low-force extension to 45 inches that minimizes fatigue during use. The coil is covered with high-strength nylon webbing that can withstand tough working conditions.

The model TL1-4025 is a flexible, low profile coil system that provides a 10-foot working radius for tools like power drills, nail guns, power drivers and other heavier weight tools. The coil system is fully enclosed in rugged nylon orange webbing that increases the tether’s overall strength and durability under tough on-the-job conditions for tools up to 25 pounds.

The new Gear Keeper models are also a high-visibility orange in colour and feature a tag that shows the weight of the tool appropriate for the tether as well as such traceability info rmation as date of manufacture,

“This safety tag is a new feature that will help safety engineers make sure that each tool has the proper tether for the job,” said John Salentine, vice-president of Hammerhead Industries. “Safety starts first with the proper mating of both the tool and the tether to ensure productivity and safety in the work environment.”

|

|

Engineered back pans

www.spandreltech.com

Galvaspan galvanized steel back pans are installed on the interior face of curtain wall systems in spandrel areas and are secured to the wall framing using appropriate fasteners. The cavity of the back pan is filled with mineral wool or fiberglass that is pin welded to the steel pan.

Galvaspan galvanized steel back pans are available in 20- or 22-gauge galvanized steel, and four profiles to suit a variety of conditions. All brake-formed, back-pan corner joints and seams are spot welded, then sealed using a butyl rubber component sealing compound. The interior side of the pans may be painted as an option when the back pans are visible from the building interior.

In curtain wall construction the control of heat flow is generally achieved through the use of insulation. Although it is not apparent from the exterior, the curtain wall system uses considerable insulation usually behind spandrel glass or any opaque panels. Because of the materials used in the structure (glass and metal) which are highly conductive, the system must also contend with potential condensation on the interior surfaces. To curtail this effect, most Spandreltech curtain wall systems incorporate three distinct features: a sealed, double-glazed window or an insulated metal pan, a thermally broken mullion, and a rainscreen design.

|

|

Versoleil expansion

www.kawneer.com

Kawneer Company has expanded its Versoleil SunShade platform. First introduced in a single blade system for curtain wall, Versoleil is now more versatile with the addition of three new sunshade systems: Outrigger for curtain wall and storefront as well as Single Blade for storefront.

Pre-engineered for multiple curtain wall and storefront systems, these flexible sunshades offer increased aesthetic choices and more solutions for maximizing shading and energy saving potential. Versoleil SunShades’ Outrigger and Single Blade systems for curtain wall and storefront applications incorporate easily into any building envelope, setting the industry standard for form and function.

Outrigger and Single Blade systems deliver the unmatched breadth and depth of application that Versoleil SunShades are known for. Engineering of common parts and pieces allows for easy fabrication and installation while a uniform attachment approach allows customers to quickly gain familiarity with installation practices regardless of system. To ensure performance criteria were being met, all systems were subjected to a rigorous testing regimen. The end results are durable, pre-engineered solutions that allow for efficient integration of Versoleil SunShades into the building envelope design and can withstand wind, snow and dead loads.

The new Versoleil Outrigger system for curtain wall is a standardized design compatible with 1600 Wall System1, 1600UT System1, 1600 Wall System5, and 1600 SS curtain wall systems. Designed with pre-engineered 90-degree and 135-degree inside and outside corner options, Outrigger is available in 30-inch and 36-inch outrigger depths. The revised mounting bracket design allows for shallow, one-inch-deep, curtain wall cover as standard. Optional deep cover also available. There are 44 different outrigger and blade combinations available with sleek blade designs including circular, airfoil, arch, planar, flare, wave, infinity, diamond and square.

Versoleil SunShades can accommodate a full range of colour options. Architectural Class I anodized aluminum finishes are available in clear and Permanodic colour choices. Painted finishes, including fluoropolymer, that meet the American Architectural Manufacturers Association 2605 standards and solvent-free powder coatings, that meet AAMA 2604 standards, are available in a variety of colour choices.

|

|

Powerful cutting lasers

Hypertherm has introduced two new HyIntensity fiber laser systems: the two-kilowatt HFL020 and the one-kilowatt HFL010. These two new systems join a 1.5-kilowatt system unveiled in 2010 as the first fully-integrated fiber laser systems designed specifically for cutting applications, including marking and fine-feature cutting.

The powerful systems deliver a number of advantages to owners. The deliver high performance on a wide range of applications and consistent cut quality across a number of material types, including brass and copper, and thicknesses up to 16 millimetres on mild steel. They operate at higher cut speeds with lower operating costs and higher productivity than CO2 lasers or plasma cutters on material thicknesses below six millimetres. HyIntensity lasers can achieve superior cut quality and tolerances for fine-feature cutting on materials from gauge to plate. They feature easy integration and installation onto existing cutting tables, even tables that already have a plasma torch.

All of the HyIntensity systems were developed and manufactured by Hypertherm in the United States, making Hypertherm the only company to offer both laser and plasma cutting expertise.

Hypertherm designs and manufactures advanced cutting systems for use in a variety of industries such as shipbuilding, manufacturing, and automotive repair. Its product line includes handheld and mechanized plasma and laser systems, consumables, CNC motion and height controls and CAM cutting software. The New Hampshire-based company’s reputation for metal cutting innovation dates back more than 40 years, to 1968, with Hypertherm’s invention of water injection plasma cutting. The company, consistently named one of the best places to work in America, has more than 1,000 associates along with operations and partner representation worldwide.

|

|

New BIM models

www.majorskylights.com

Major Industries, manufacturer of energy-saving skylights and translucent curtain wall, is pleased to announce the release of BIM product models for our Guardian 275 line of translucent panel skylights and wall systems.

Major’s product models were created with the architect in mind, and offer small file sizes and emphasize ease of use. BIM content is available for all of Major’s most common skylight configurations as well as both window and curtainwall options to accommodate a wider range of users.

Guardian 275 BIM product models are currently available for download from the BIM page on Major Industries’ website.

|

|

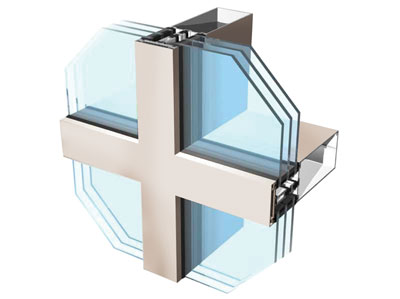

Energy-efficient curtain wall

www.crlaurence.ca

The U.S. Aluminum Series HP3253 high-performance curtain wall system for two-inch efficient triple-glazed infills features Dual Thermal Break technology using the Poly-Aluminizer thermal break. Thermally isolated by a continuous thermal spacer it has been especially engineered to satisfy the need for energy conservation. Two-tone colors can be achieved by using different finishes for the exterior face members and the interior mullions. The HP3253 curtain wall features stick erection with no exposed joint fasteners.

Print this page

Leave a Reply