Oct. 20, 2009 – Engineers across a wide variety of industries know welding the

Oct. 20, 2009 – Engineers across a wide variety of industries know welding the

tempered aluminum profiles (extrusions) that most aluminum glass

carriers are constructed from, actually weakens them.

|

|

| Mechanical fasteners

|

Oct. 20, 2009 – Engineers across a wide variety of industries know welding the

tempered aluminum profiles (extrusions) that most aluminum glass

carriers are constructed from, actually weakens them.

Q

Why does MyGlassTruckTM construct aluminum glass carriers with mechanical fasteners instead of welds?

A

To manufacture the most durable aluminum carriers available that provide our clients with years of trouble-free performance.

While designing our Aluminum Value-Line of carriers our engineers asked questions like, "Why aren't welds used to hold airplanes together? How are store front window systems assembled? What fastening system is used to fabricate eighteen-wheeled semi-trailer bodies?" Turns out they're all constructed using mechanical fasteners.

In fact, our racks are superior because they are held together with mechanical fasteners, not welds.

Facts About Welded Aluminum

Here's the short list of things you need to know about welded aluminum:

- Welding creates a "local heat affected zone" that makes the material around the weld brittle and more prone to breaking.

- Welds are much more susceptible to fatigue than mechanical fasteners.

- When aluminum cracks it usually begins at the weld.

- Due to the high shrinkage rate of aluminum many structural engineers believe that all aluminum welds have microscopic cracks when they cool.

- Welds are more difficult to repair in the field than mechanical fasteners.

- Welding aluminum is considered an "art" and the strength of each weld can't be guaranteed. If a welder has a "bad day" you'll probably get bad welds.

- Today's modern welding machines provide quick and inexpensive welds, but the trade-off is inconsistent quality from worker to worker and day to day.

MyGlassTruckTM does not use nuts and bolts, pop rivets or screws to fasten the structural components of our Glass Racks / Glass Carriers.

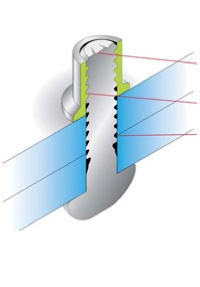

These are the same heavy-duty fasteners used throughout the aerospace industry. They're similar to a bolt, but the nut is actually crimped onto the shaft with a specialized tool.

|

|

| Huck fasteners

|

Huck fasteners offer many advantages over welding:

Vibration proof – absolutely will not loosen due to stresses produced by highway driving.

Flexibility – lock bolts provide a secure bond with less rigidity to prevent cracking at joints.

Consistency – the clamping force of each fastener is guaranteed to be uniform throughout construction.

Doesn't compromise aluminum's strength – lock bolts possess high shear and tensile strength but won't weaken the metal surrounding them.

No special training needed – can be installed consistently by any worker on the assembly team and visually inspected each time to ensure quality.

Speedy installation – less time spent on assembly allows us to pass savings onto you.

Easy to field-service – fasteners can be cut off and quickly replaced with conventional bolts and lock nuts.

The Huck Magna-Grip Fastener

- Flush-breaking, lock-groove design offers a wide grip range and easy, consistently accurate installations.

- Collar material swaged into the annular pin grooves forms a permanent, vibration proof connection.

- Hole preparation isn't critical. Built-in system values yield high, consistent clamp loads and gap removal.

- Perfect installations do not depend upon worker skill or a precisely calibrated impact wrench – and can be achieved with just a few minutes training.

MyGlassTruck™ Glass Racks for Vans and Trucks are distributed exclusively in Canada, for more information visit: http://www.canadianvan.com

Support: 1-888-774-0775

For more information:

Aluminum glass carriers and glass racks

http://www.canadianvan.com/index.php?cPath=93

Print this page

Leave a Reply