Custom pickup racks

Custom pickup racks

www.theglassrackingcompany.com

|

The Glass Racking Company provides a comprehensive range of glass racks for pickup trucks, including both tray bed and OEM box racks. Tray bed racks fit into the base cab chassis providing carrying capacity through the full bed, plus carrying racks outside the wheels on both sides. They are suitable for dedicated glass-carrying vehicles and those requiring large volumes and sheet sizes. A-frame racks are removable and have a storage unit built inside the A-frame. They work best for multi-purpose glass carriers with smaller volumes and users who need to retain the use of their factory beds. A range of racks for OEM beds is also available in single, double, triple or quad designs.

All Glass Racking Company racks can be configured with lengths and heights to suit the user. Gas fill ports can be moved for easy access even when the racks are loaded. A removable module allows access to the wheels. An 18-inch extension is standard on the driver side and optional on the passenger side. Standard lights can be replaced with LED lights for easier installation and maintenance. Company signage and branding is available.

Strength and load-bearing is maximized by T6 aluminum extrusions for the main rack construction, supported by a galvanized steel sub-frame and top and bottom rack brackets. The rack is all aluminum for strength and reduced weight. Glass Racking Company racks add significant capacity by maximizing the external ledge width and the overall rack dimensions. The high-tensile, mono-bolted construction allows for easy repair and maintenance.

Versatile channel lifters

www.powrgrip.com

The P1 and P2 Series vacuum lifters from Wood’s Powr-Grip deliver reliable, cord-free operation on the job site or in the plant. These modular vacuum lifters are configured with one or more pad channels and interchangeable lift frames to meet a variety of glass handling needs. Interchangeable lift frames provide manual 180-degree rotation and 90-degree tilting of loads. Pad channels can be switched from one lift frame to another in minutes, for maximum versatility at the installation site. This innovative system of interchangeable lift frames and pad channels provides load capacities up to 1,400 pounds. On-board DC power permits use with cranes, forklifts or floor hoists. When combined with the CB1 counter-balancer, double-channel vacuum lifters can be used to install windows under overhangs or in other low-clearance settings.

Automatic cutting

www.bystronic.com

|

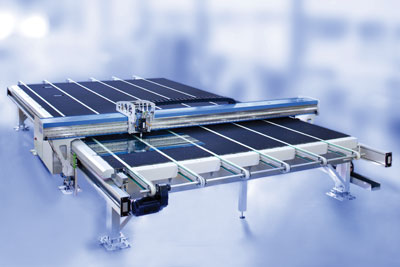

Bystronic glass has underlined its decade-long expertise in glass cutting with the introduction of the Speedcut float glass-cutting table. Thanks to its modular concept, the Speedcut is highly versatile and can be used for cutting architectural glass during pre-processing for photovoltaic modules, or for cutting automotive glass or special glasses.

Speedcut provides speed up to 300 metres per minute and acceleration up to six metres per square second. The deployed measuring system improves precision on the desired dimensions, reducing grinding tolerances to a minimum. The cutting bridge is driven by modern linear technology. This replaces the previous common combination of racks and sprockets and significantly reduces maintenance outlay. The Speedcut works more quietly in production than older cutting tables thanks to this drive.

“The Speedcut can offer energy savings because of the honeycomb structure of the cutting bridge. The bridge is designed to be significantly lighter than comparable elements in conventional structures and is extremely stable. The low weight of the cutting bridge leads to a 20 per cent reduction in energy use for acceleration and braking. The cutting head is individually manufactured by Bystronic glass and is processed by hand for each machine. The Speedcut’s edge deletion unit has been adjusted to meet the requirements for ever-harder glass coatings. In combination with the new control, the operator obtains comprehensive process information. Multiple cutting oil circuits for different glasses as well as an automatic tool changer make operational manual interventions almost unnecessary.

Sawtooth handling system

www.theglassrackingcompany.com

|

The Glass Racking Company has been supplying equipment to speed the processing of glass between factory machinery for glass processors for 20 years. The Glass Racking Company supplies a full range of factory handling equipment including stoche glass storage, single glaze and IGU harp carts, pin carts, A-frames, spacer racks and spacer carts, tooth carts, finished goods storage, lifting and transportation solutions.

The bearing surfaces on our equipment are made of a purpose-built polymer that is hard-wearing, soft, and non-marking. This means no rubber marks and reduced scratches on the finished product leading to less rework costs. All carts have quality six-inch casters, hot-dip galvanized finishes and solid steel construction. All equipment is designed with the needs of the glass and window industry in mind.

The Glass Racking Company tooth storage is a unique racking system that holds IGUs, windows and doors secure for storage and movement around a plant. No hard surface touches the glass or window, which reduces scratching damage. Toaster-style storage speeds access to specific items.

Belt conveyor furnace

www.grievecorp.com

|

Grieve Corporation introduces No. 811, a 1,600 F, gas-heated, belt conveyor furnace, currently in use for forming glass in alloy moulds at a customer’s facility.

Workspace dimensions inside this unit measure 24 inches wide by 12 feet deep by 22 inches high. Workloads travel atop a six-inch-wide, B-30-28-14, Type 314, stainless steel mesh conveyor belt with a 1/4 horsepower motor drive and a fixed speed 12 feet per minute. The open-belt loading zone is 36 inches long and the insulated heat zone measures 12 feet long with three direct-fired furnaces and a 24-inch open unloading zone.

Three modulating gas burners generate 1,320,000 BTU per hour with a floor-mounted combustion air blower (not shown in photo). The seven-inch thick insulated walls are made with five-inch, 2,300 F ceramic fiber and two-inch block insulation. The 6 ½-inch thick floor insulation is made up of 4 ½ inches of 2,300 F firebrick and two-inch block insulation. Vertical lift doors at each end of the workspace provide further insulation.

A remote, free-standing control panel (not shown in photo) is also included with this Grieve furnace, which features all safety equipment required by IRI, FM and NFPA Standard 86 for gas-heated equipment.

Print this page

Leave a Reply