Features

Machinery

Look up, way up: Advancements in swing stage safety and technology

The evolution of the lift technology we depend on has accelerated in recent years.

December 1, 2020 By Treena Hein

The ANSI Safe Use standard requires companies to develop a MEWP safety program and then share it with all workers on a site where the equipment is being used.

The ANSI Safe Use standard requires companies to develop a MEWP safety program and then share it with all workers on a site where the equipment is being used. Today’s commercial glaziers are constantly up on swing stages, aerial work platforms and boom lifts. The use of crane and telehandlers is common as well. To provide more aerial capabilities to the glazing industry and construction trades in general, companies have greatly increased the lifting capacity of many mobile elevating work platforms, notes Matthew Elvin, CEO at Snorkel.

“Twenty years ago, the standard lift capacity was 500 pounds for many boom-type work platforms. But the industry is moving towards 600 pounds as the standard. And with restricted envelopes, this can increase to as much as 1,000 pounds platform capacity,” he explains. “This offers many benefits to the glazing industry as this equipment can carry more tools, more personnel or more glass and other materials to the working area.”

Lifting capacity aside, the need to work on taller buildings, adds Nate Hoover, has also pushed the aerial access equipment industry to go higher. “In just the last decade, boom lifts have seen dramatic increases in height, providing glaziers access to areas previously unattainable,” explains the director of marketing and product management at JLG Industries.

Among the types of mobile elevated work platforms (MEWP) now available are articulated and telescopic lifts, mast climber work platforms, and also towable, compact crawler and scissor lifts. And of course, many factors – including worker safety – come into play when deciding which is best. Careful consideration should be given, says Hoover, to the type of work to be done, height requirements, obstacles the boom may need to manoeuvre up and over, tools and materials the platform will need to support, the space in which the boom will need to operate and the number of people.

Number of people on an aerial lift has of course been affected this year by the COVID-19 pandemic. Because of the size of mast-climbing work platforms (MCWP), they can be a much better option for socially distanced work than a MEWP, according to Thierry LaChapelle, executive vice president of AGF Access Group in Montreal, which manufactures a variety of access products including Hydro Mobile MCWPs.

Elvin adds that many MEWPs “based on their capacity, especially when loaded with materials such as glass, may naturally restrict occupancy to one person. And given the heights and reach capability of this equipment, social distancing is provided almost by necessity. Other types of equipment, such as large, high-capacity scissor lifts have platforms that are large enough to provide adequate separation of occupants. Of course, there will always be jobs where it is mandatory that personnel be in close contact and for those situations, they need to follow the proper protocols.”

The need to work on taller buildings has pushed the aerial access equipment industry to go higher.

Knowledge is power

Telematics and data collection are becoming more widespread in all equipment now, relating to usage, battery life and more, but Elwin believes that in lift equipment, this type of technology is still in the infancy stage. According to LaChapelle, while telematics are useful with MCWPs, they are not essential. “This being said, we are currently investigating on how to better integrate telematics to our transport platforms systems,” he says.

Most telematics systems today provide a view of machine location and hours, and sometimes, error and maintenance messages. “However, we see this developing to provide additional information on usage, loads and duty cycles,” says Elvin, “to help equipment managers determine if they need larger or smaller equipment, how often equipment is utilized and does equipment meet the loading requirements for a particular jobsite.” He adds that as telematics capabilities grow, rental companies will be able to rent out equipment remotely, allowing equipment located at mega-worksites to be used by different contractors. Renting equipment already on-site reduces delivery costs and job timeframes, and are especially useful for relatively quick tasks that arise quickly.

In its boom lifts, JLG has recently introduced SkySense, an object-detection system that provides operators with added awareness of their immediate surroundings. The system’s sensors establish warning zones and stop distances in the machine’s direction of motion. And, for its rough-terrain scissor lifts, JLG offers QuikLevel Advanced, which allows its machines to work at full height in certain conditions on slopes up to 4.5 degrees. Hoover says that when combined with the standard LiftSense feature on all new JLG RT and electric rough-terrain scissor lifts, operators can determine how high they will be able to reach prior to elevating, based on front-to-back and side-to-side tilt, as well as actual weight in the platform.

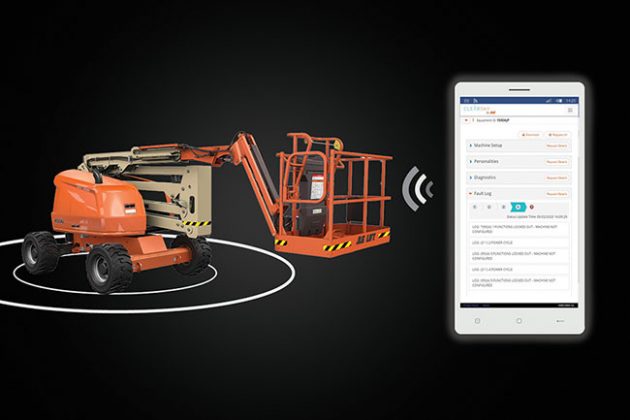

In February 2020, JLG also introduced ClearSky Remote Analyzer Reader (the ClearSky telematics platform was first introduced in 2008). This allows service departments to remotely diagnose qualitative operational issues, check the on and off status of connected technologies, review the last 25 fault codes and more.

Other new tech, for safety and more

Prior to the arrival of the new Snorkel 2100SJ (which Snorkel says is the world’s tallest self-propelled boom lift at 216 ft/66 m), some types of work may have required a MCWP or scaffolding. A self-propelled MEWP in these situations offers virtually no set-up or dismantle time, which, according to Elvin, enables operators to quickly and safely return equipment to the stowed position in the case of winds or other hazardous weather. He adds that “carrying glass panes or panels has also been made safer and easier with the development of specific glazier accessory packages for MEWPs, such as the optional Snorkel Glazier Package. This features two rubber-lined trays with keeper pins for supporting the glass panels, as well as padding for the platform rails and heavy-duty straps.”

For LaChapelle part, he doesn’t see it as straightforward to make safety comparisons between MCWPs and MEWPs, but notes that every time workers must move a man lift, there are risks. “Glasswork is usually performed on a structure that is already built and glaziers are typically looking for a working capacity of 4,000 to 6,000 pounds, typically across 40 to 60 feet on a single unit or 100 to 120 feet on a twin unit,” he explains. “MCWPs offer this, and you can add sections that attach to the building to over 1,000 feet, suitable for smaller curtain walls and other work. We also have accessories such as hoists. I think our transport platform for applications up to 100 feet provides added safety because it allows people and materials to be transferred from the outside of a building to the inside without the need for a boom truck, crane or inside elevator.”

Through the advanced telematics systems of today, it is possible to obtain a view of machine location and hours, and even error and maintenance messages.

ANSI standards

ANSI (the American National Standards Institute) recently updated standards relating to design and more of MEWPs. Older equipment is still acceptable for use, and it’s not necessary to bring equipment manufactured prior to June 2020 into compliance with A92.20 (the ANSI standard for the design and testing of equipment, which relates to CSA standard B354.6).

However, Elvin says the other new updated standards (A92.22, Safe Use of MEWP, which relates to CSA B354.7, and A92.24, Training Requirements, which relates to CSA B354.8) need to be understood and followed by owners, users, operators and occupants of MEWPs. These standards help users become familiar with new equipment features they may be exposed to due to ANSI A92.20, such as indoor versus outdoor-rated equipment, and platform load sensing.

According to Hoover, the new load-sensing capabilities on lifts means the equipment will automatically come to a halt if the platform is overloaded. “So, more advanced planning is required,” he says, “and choosing the right MEWP is increasingly important to ensure it can perform at peak efficiency once on the job.”

One of the main requirements of the ANSI Safe Use standard is companies must develop a MEWP safety program and then share it with all workers on a site where the equipment is in play. Hoover adds that with regard to the ANSI Training Requirements standard, all training must be delivered by a qualified person who is experienced with the particular classification of MEWP to which the training pertains.

“While MEWP operator training is still mandatory,” he adds, “this requirement now extends beyond operators to include supervisors, occupants and maintenance and repair personnel.” The training standard also requires that dealers offer training and familiarization to anyone who rents, leases or buys equipment. •

Print this page

Leave a Reply