Technology

Insulating Glass

Necessity drives trends

The natural evolution of sealing and bonding in fenestration.

April 7, 2011 By Hélène Coupal

The availability of a comprehensive range of polyurethane and silicone

products specifically designed for use in the fenestration industry is a

testament to the unmistakable and diverse benefits of sealants.

The availability of a comprehensive range of polyurethane and silicone products specifically designed for use in the fenestration industry is a testament to the unmistakable and diverse benefits of sealants. Polyurethane and silicone sealants and adhesives are widely used in general-purpose weather sealing and structural glazing, as well as the manufacture of insulating glass and curtain walls installation. It is impossible to imagine the fenestration industry existing without them.

|

|

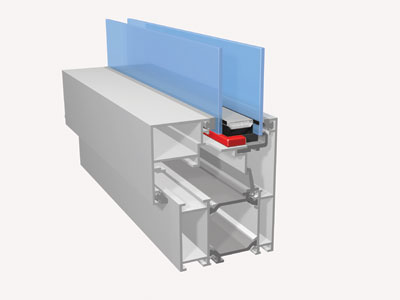

| By using adhesives all around the perimeter of the glass to adhere it to the frame, you can use a smaller-profile window frame. The adhesive, shown in red, can be placed in different areas, depending on the manufacturing process.

|

Notwithstanding the undisputed value of sealants, architects, contractors and building owners today are progressively looking for much more than simple UV-, water- and weather-resistance. Increasingly, demands are being placed on sealant manufacturers to contribute to meeting requirements for increased energy efficiency, design flexibility and decreased frame profiles, which allow improved light penetration. Ever-evolving building designs and codes mean increased dynamic load support is also sought. Add to this the ever-present requirement for decreased manufacturing production costs and you can readily appreciate the competing and often contradictory demands being placed on the sealing and bonding manufacturers who supply the fenestration industry.

Increasingly, our group has undertaken the challenge to manufacture sealants that offer improved bonding capabilities. In Europe, where things are built to last, we have developed bonding and sealing products specifically for window manufacturing processes that fully bond the perimeter of the glass to window frames. This allows the glass to impart structural strength to the frame, as opposed to traditional building methods where the frame imparts strength to the glass. Much like the car industry, mechanical fixations are being slowly reduced, giving way to less expensive manufacturing processes that rely heavily on adhesives to impart structural strength. Cars today, for example, are lighter and less expensive to manufacture thanks to a reduction in the quantity of steel used to manufacture them. Yet their structural integrity has been maintained, and even increased, due to the use of adhesives to complement the mechanical fixations used in their manufacture. Crash tests have shown conclusively that structural members strengthened with adhesives far outperform structural members solidified uniquely with mechanical fixations.

Technological advances in one industry naturally lead to technological advances in another, and the fenestration industry is no different. Slowly but surely, Sika is introducing the bonding technologies it developed for the automotive industry into the fenestration industry. These innovative manufacturing processes have resulted in the glass assuming greater responsibility for providing structural strength to windows and have, in turn, made it possible to design window frames with reduced profiles, which allow for lighter, less expensive frame designs and, most importantly, for more light to penetrate the buildings they grace.

Adhesives used in this way in the manufacture of windows (for example, to replace blocks and wedges) provide greater strength and greatly reduce the failures that often occur when transporting finished windows to installation sites, thus reducing post installation service calls and glass replacements.

|

|

| Armed with advanced sealants and adhesives, architects working with glass will be limited only by their imaginations.

|

In the manufacture of insulating glass, the requirement for increased performance of the secondary IG sealant continues to grow as innovative building designs are introduced by architects. Where, traditionally, polysulphide-type sealants are used in the fabrication of insulated glass units, they do not offer the structural stability silicones do. Silicones are critical for fabrication of IG glass when replacing traditional methods of installing glass onto building façades because they replace metal and mechanical type fasteners when attaching glass and panels to building frames. This results in the creation of continuous flexible rubber seals and anchors that absorb and transfer stresses, while preventing air and water intrusion. We are currently engaged in introducing these processes into Canada, where the obvious benefits of these manufacturing processes are steadily gaining in popularity.

For homeowners and building professionals alike, the attraction is apparent: greater design freedom, more attractive windows and increased light penetration along with windows built to the most stringent building codes. •

Print this page

Leave a Reply