Technology

Insulating Glass

Besten enables triple insulating glass unit

October 1, 2009 By Administrator

NEWS HIGHLIGHT

NEWS HIGHLIGHT

Besten enables triple insulating glass unit

Besten Equipment, Inc. has added a triples

option to its automated TAPE MT1500 insulating glass production

line.

Oct. 1, 2009 – Solon, Ohio – Besten Equipment, Inc. has added a triples option to its automated TAPE MT1500 insulating glass (IG) production line, enabling IG fabricators to produce between 650 and 750 triple IG units per shift on a single line.

|

|

|

|

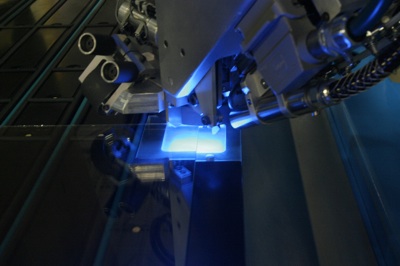

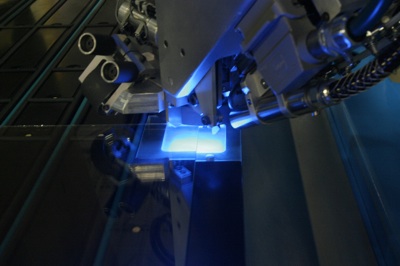

Besten’s TAPE MT1500 enables high-capacity dual-glazed or triple-pane IG unit production via parallel glass processing and spacer application on a horizontal bed. The line features two applicators, which each apply flexible, warm edge spacers to the inside edge of the outer glass lites of a triple IG unit. The intermediate center lite passes through the application bed, and the three lites are assembled into an IG unit via tilting air float assembly tables. Optional muntin grid placement, made easier by inkjet printing alignment marks on the spacer, is permitted before the assembly.

Finally, an optional integrated Quik-Dose™ gas-filling system enables argon filling in process for a complete, ready-to-ship IG unit right off the production line. The automated process greatly improves production and labor efficiencies for IG fabricators.

Cycle times for triple IG unit production are as low as 28 seconds per side, using just three or four operators. In addition, mix-mode production allows continually variable IG unit sizes to run simultaneously, helping fabricators accommodate production schedules and special orders.

“The marketplace is facing increasingly stringent energy performance criteria, which means fabricators will soon be producing more and more triple IG units,” said David Marlar, Besten’s general manager. “Besten strives to help fabricators meet these needs by enabling the costeffective production of highly thermally efficient IG units. Triple IG unit production using the TAPE MT1500 gives fabricators a very productive manufacturing option that also minimizes labour costs.”

With the TAPE MT1500, IG fabricators have the option to produce offset triples by loading the two applicator heads with spacers of different widths. In an offset triple, one glazing cavity is Besten Enables High-Capacity Triple Insulating Glass Unit Production wider than the other to carry a muntin bar grid without breaching the 3-millimeter grid proximity rule.

Without an airspace of 3 mm or greater between the grid and the inside glass edges of the glazing cavity, the grid must be thermally modeled into the spacer. Such a design detracts from an IG unit’s overall thermal efficiency as the modeled-in aluminum grid subsequently transfers cold and heat at the edge of the glass. Offset triples let producers place grids completely inside the glazing cavity so they will not detract from an IG unit’s overall U- or R-value.

“The ability to run dissimilar airspaces for an offset triple-glazed design is a big benefit for IG fabricators,” said Kevin Zuege, technical services director for Truseal Technologies, Inc. “It gives them more options for grid placement, gas filling and, ultimately, thermal efficiency. Some fabricators may choose to insert a grid and argon gas in the wider glazing cavity and either leave the other cavity filled with air or add argon or krypton gas to fine tune or further enhance the efficiency of the IG unit.”

To ensure proper placement of spacers in relation to the edge of glass, the TAPE MT1500 features novel camera squaring technology built into the applicator heads. When a glass lite stops beneath an applicator, the digital camera snaps a picture, and the equipment instantly adjusts for the location of the lite on the application bed. Spacer application starts immediately there after, saving time in the spacer trace cycle and allowing for more units to be produced per shift.

Fabricators producing double-pane IG units with the TAPE MT1500 are able to produce between 1,400 and 1,600 units per shift on a single line. The equipment reduces double-pane IG unit cycle times to as low as 14 seconds – or two units every 28 seconds with both applicators running – using only five operators. The equipment is compatible with Truseal Technologies’ Dura Platform flexible spacer systems, which include both Duralite® and Duraseal™ spacers.

Print this page

Leave a Reply