Features

Fabrication

Innovations

Opening markets with nano-technology

.. nano-technology

May 8, 2008 By Diamon-Fusion International

Nano-technology is a technology based on the manipulation of individual

atoms and molecules to build structures to complex, atomic

specifications.

Nano-technology is a technology based on the manipulation of individual atoms and molecules to build structures to complex, atomic specifications. While many definitions for nano-technology exist, the National Nano-technology Initiative (NNI), a federal research and development program in the US established to co-ordinate the multi-agency efforts in nano-scale science, engineering and technology, defines ‘nano-technology’ as:

• Research and technology development at the atomic, molecular or macro-molecular levels, in the length scale of approximately 1-100 nano-metre range.

• Creating and using structures, devices and systems that have novel properties and functions because of their small and/or intermediate size.

• Ability to control or manipulate on the atomic scale.

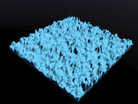

| Figure 1. Untreated glass |

|

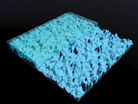

| Figure 2. First stage ‘fills in’ |

|

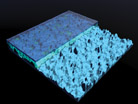

| Figure 3. Second stage ‘caps’ |

|

| Hydrophobic nano-technology coating works at nano-scale levels to change the molecular composition of any silica-based surface. Called Diamon-Fusion, it provides a cross-linked, branched and ‘capped’ coating along with a strong and durable covalent bond where the coating shares the electrons within the glass itself, becoming a part of the glass. |

Molecular composition

Diamon-Fusion International (DFI) employs a hydrophobic nano-technology coating, a patented process that works at nano-scale levels, approximately 30 nano-metres, to change the molecular composition of any silica-based surface. Called Diamon-Fusion, it provides a cross-linked, branched and ‘capped’ coating along with a strong and durable covalent bond. A covalent bond means that the coating shares the electrons within the glass itself, thus becoming a part of the glass.

Covalent bonds are approximately 10 times stronger than hydrogen-bridge bonds, which are commonly present in most other water-repellent coatings. The change of the molecular composition of the silica-based surface created by DFI’s chemistry and bonding nano-particles, along with the cross-linking, branching and final ‘capping’, enables the full efficiency of the coating process at an atomic scale.

The nano-scale is about a thousand times smaller than micro, that is about 1/80,000 of the diameter of a human hair. Approximately three to six atoms can fit inside a nano-metre, depending on the atom. The prefix nano means 10 to the minus ninth power, or one billionth. Nano-scale technologies are the development and use of devices that have a size of only a few nano-metres.

Product applications

Numerous products featuring the unique properties of nano-scale materials are available to industry today. Nano-technology is used in electronic, magnetic and optoelectronic, biomedical, pharmaceutical, cosmetic, energy, chemical-mechanical polishing, magnetic recording tapes, sunscreens, automotive catalyst supports, bio-labelling, electro-conductive coatings and optical fibers.

Although the main applications of nano-technology have been developed in the computer and electronics fields, the most other current use for this technology is applied to coating glass surfaces.

Exterior glass windscreens have become popular in the last 10 years. In the residential and commercial building sectors, treated glass surfaces make glass easier to clean because water spots take longer to appear and when they do appear, are much easier to remove. Maintenance is less frequent because the treatment makes dirt and debris run right off.

Applications for glass markets include:

• Guardrails – both interior and exterior are typically very expensive. Most owners find them quite a chore to keep clean and prevent scratching.

• Ceramic tile – for bathrooms, kitchens or in swimming pools and spas.

• Glass shower enclosures – well known for being difficult to clean and maintain.

• Sandblasted or etched glass – this popular application is used for two main purposes. Architects will specify sandblasted glass as a means for allowing light to come into a room while still holding privacy. The inherent problem with this type of glass is that it stains very easily and shows fingerprints that typically cannot be removed. The glass also becomes water repellent so any water that would have created a dark and wide stain prior to treatment, now beads up and runs off in a hydrophobic effect.

• Skylights: residential – the use of skylights in homes has increased significantly over recent years. More architects are designing interesting geometric shaped skylights as part of the homes’ overall design and not just simply as a way of bringing in more natural light. With the advent of high performance glass that can control heat, light and ultra-violet rays, many applications previously thought to be poor locations are now being used. The problem that up until now had not been solved was the difficult maintenance that is required because of the access problems. Now every time it rains all the dirt runs right off.

• Skylights: commercial – many of the same issues apply as in residential skylights. What needs to be pointed out is that major commercial projects like convention centres, hotels and shopping malls are being specified by architects to include more and more glass skylights. With the high cost of maintaining skylights in extremely difficult to access commercial locations, the maintenance reducing abilities this technology brings to the market is a very viable solution.

• Sunrooms/solariums/conservatories – most of the same issues related to skylights apply to these also.

While nano-technology has many applications in different industries, its application in commercial and residential glass markets give manufacturers, fabricators and glazing contractors the opportunity to service a wide range of new markets that have been created with these new innovative glass products. -end-

Article courtesy of Diamon-Fusion International, Inc. (DFI), based in San Clemente, California. Diamon-Fusion is a registered trade mark of DFI, the global developer and exclusive licensor of the patented hydrophobic nano-technology. Prelco Inc. in Rivière-du-Loup, Quebec, is licensed to distribute DFI’s nano-coating under its own brand name Nano-Fusion and is one of DFI’s Global Strategic Partners. For more information about nano-technology visit: www.DFInanotechnology.com and the National Nano-technology Initiative (NNI) at: www.nano.gov/html/facts/whatIsNano.html

Print this page

Leave a Reply