Technology

Hardware & glazing systems

Curtainwall showcase

Technology that can give you a competitve edge in your next bid.

December 3, 2015 By Monica Dick

Technology in curtainwall components can drive your profits. Check out the latest offerings from these top fabricators.

Hidden and protected

commdooraluminum.com

For more than 25 years, Commdoor architectural aluminum products have been available to the glass and glazing industry. With the introduction of new thermal performance requirements such as SB 10 compliance, it was necessary for Commdoor to be able to offer such a system for its loyal customers. The initial series 8000 curtainwall currently available utilized standard curtainwall design based on a thermal break between the back section neck and the pressure plate. The newest version, the Commdoor Curtainwall System 8200 Series HP series now offers a dual polyamide thermal break which is capable of achieving the desired thermal performance. The system face width is 63.5 mm with five back section depths available from 101.6 mm to 254 mm. Traditional caps and pressure plates are available along with structurally glazed versions offered in stock lengths up to 7,366 mm. Available in both traditional stick and split vertical mullion versions, this provides greater flexibility to suit varying job site applications. This curtainwall system is designed for the low- to mid-rise building designs and is desirable for its ease of shop fabrication and “field friendly” installation. The 8200 HP series is designed to accept a variety of infills, glass and glazing up to 44.5 mm triple-glazed, along with Series 225 operable vents, 2000 series SSG vents, and commercial doors including the series 4487 high performance terrace doors. Most system profiles are in stock in either clear or bronze anodized finishes, with custom colors also available.

Designed for today’s energy codes

tubeliteinc.com

Designed for today’s stringent energy codes Tubelite has introduced its 400TU Series high-performance thermal curtainwall system for medium- and low-rise commercial buildings. Combining aluminum framing, dual thermal strut and high-performance insulated glass, 400TU Series dual-glazed achieves industry-leading U-Factors of 0.30 for thermal transmittance and a frame condensation resistance factor (CRFf) of 81. Thoroughly tested by an independent laboratory, Tubelite’s 400TU Series curtainwall demonstrated that it meets or exceeds ASTM and AAMA industry standards for air, water, structural, thermal, acoustical and seismic performance. The 400TU Series curtainwall’s enhanced thermal break is located in the tongue area of the back member, and the insulated glass is positioned to the system’s exterior for enhanced resistance to rainwater. In addition to thermal performance, this curtainwall system is tested to meet acoustical performance ratings for Sound Transmission Class (STC) 38 and Outdoor-Indoor Transmission Class (OITC) 32. Assembled using screw spline or clip joinery, 400TU Series can be specified with either an aluminum or polyamide pressure plate, and as a stick-built system or shop-assembled into “ladders” for field glazing. Verticals can be steel-reinforced for strong windloads. The system’s 6-, 7.5- and 10-inch system depths can accommodate glass or panels of 1- to 1.75-inches thick, and easily integrates with Tubelite’s ThermlBlock entrance systems. Tubelite’s 400TU Series can be extruded using EcoLuminum, a high recycled-content aluminum billet composition with eco-friendly, durable finishes. Seven anodized finishes and 20 standard paint colours are available, and upon request, blended and custom colours may be specified. Durable finishes reduce buildings’ maintenance costs and enhance long lifecycles. Coupled with 400TU Series’ recycled aluminum content, daylight, views, energy-efficient thermal performance and condensation resistance, these attributes also may support projects seeking LEED certification or other green building criteria.

Comprehensive line

metroaluminum.com

Metro Aluminum’s 2400 Series (two-inch site line) and 2500 Series (2 ½-inch site line) curtainwall systems in 6063 T6 Aluminum Tubular profiles offers a complete line to meet the design criteria set forward by architects and designers. Thermally broken and triple-glazed high-performance back sections are also available to comply with the energy efficiency standards. With back sections from as small as two-by-two to 2 ½-by-eight inches and available in a variety of anodized and painted finishes, Metro Aluminum delivers a comprehensive line for every budget and design. The optional fiberglass pressure plate will improve energy efficiency and thermal results. Metro Aluminum products qualify for LEED points using recycled content the manufacturing practices, ultimately leading to a smaller carbon footprint. Metro Aluminum is an innovative and forward thinking Canadian company, expanding its product lines to include sunshades to work with its curtainwall systems.

Tested with superb results

alumicor.com

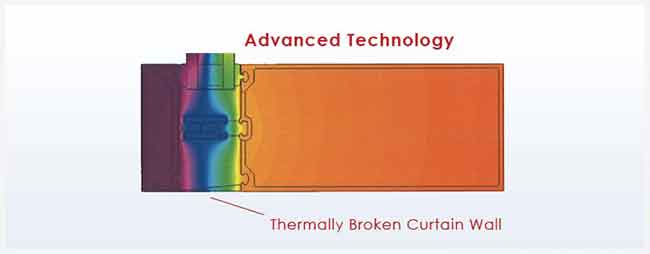

Alumicor offers innovative pre-glazed systems with creative options to meet the ever-changing needs of today’s design and performance requirements. Choose ThermaWall 2600 stick built for the greatest possible thermal performance. it is a true thermally separated curtain wall system that incorporates proprietary Bigfoot thermal break technology. ThermaWall 2600 is a stick-built system available in double- or triple-glazed infills and can accommodate vertical and horizontal structural silicone glazed designs. Experienced designers and glazing contractors will appreciate the integral glass supports that completely eliminate the transfer of IGU dead loads to the thermal break. ThermaWall 2600 has been rigourously tested to AAMA and CSA standards with superb results. For a high-performance prefabricated/pre-glazed split mullion curtain wall, Alumicor offers ThermaWall SM 2600 with a 63.5 mm profile in both double- and triple-glazed. The split mullion and expansion/stack horizontal makes prefabricated or pre-glazed panel installation a snap.

Shop glaze then ship

obe.com

Reliance Cassette Curtain Wall from Oldcastle BuildingEnvelope is a four-sided structurally glazed system that allows the installer to shop glaze the infill onto “cassette frames” using 3M VHB structural glazing tape or structural silicone. These pre-glazed frames are then taken to the field and applied to a structural grid of standard Reliance or Reliance-SS curtain wall framing providing a four-sided structurally glazed appearance with an overall system depth of 6-3/4, eight or 10-1/2 inches. This system can be used in either new construction or retrofit onto existing Reliance or Reliance-SS installations. The system includes thermally improved door-framing adaptors, which can accommodate the use of Oldcastle BuildingEnvelope Thermal Entrances to complete a thermal elevation. Reliance Cassette can also accommodate exterior face caps to provide unique architectural framing features or transition to a standard Reliance or Reliance-SS curtain wall installation.

Print this page

Leave a Reply