Features

Glass

This month’s top-pick products for architectural glaziers

October 12, 2022 By Glass Canada Staff

Fire-safe windows

Fire-safe windows

Gaskets, curtain walls and stainless-steel spacers…here are the glazing products that caught our eye.

Fire-safe windows

stifirestop.com

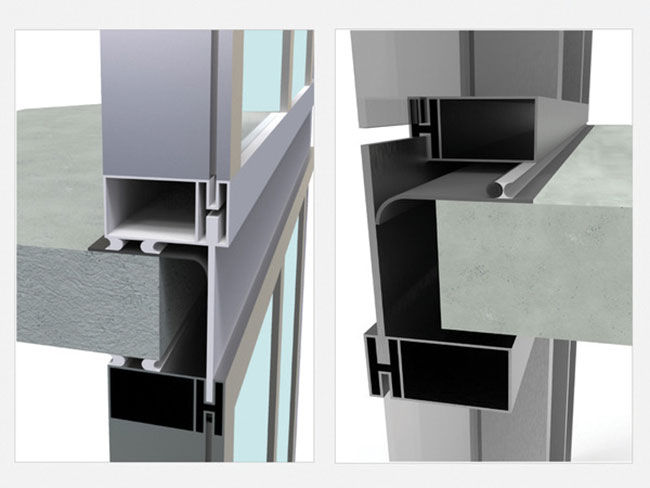

The SpecSeal window wall gasket from Specified Technologies is a rubber gasket embedded with glass fiber mesh. It’s designed using intumescent rubber, making it great for firestopping at the edge of slab in window-wall construction. The gasket has a glass fiber mesh embedded within the rubber matrix and is faced on both sides with polyethylene film to stand up to normal jobsite rigors and the typical exposure to the elements. The window wall gasket can be secured to the edge of slab or directly to the window-wall unit sill to drape into the gap between the floor and the slab cover. The gasket expands quickly when exposed to temperatures higher than 177 C and forms a dense, insulative char for fire protection. The gasket is tested to ASTM E2307 for window wall assemblies and it’s designed for window wall and hybrid window wall construction. It can also be used with common exterior grade sealants. The gasket can be installed to top-of-floor or directly to panel framing.

Ultra-thermal unit walls

kawneer.com

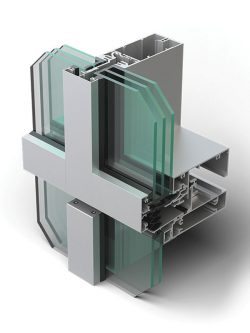

Kawneer’s 2500 UT unit-wall system is a sleek glass unitized curtain wall with ultra-thermal performance. It’s designed with a continuous polyamide thermal break vertically and horizontally, providing ultra-thermal performance levels in a cost effective unitized curtain wall system. The one-piece polyamide thermal break eliminates pressure plates and fasteners, reducing the amount of metal used and time required to assemble the system. The framing system is cost-effective and reduces the time to fabricate, assemble, glaze and install. The 2500 also comes with a variety of flexible options – from four-sided captured exterior covers to structural silicone glazed or structural glazing tape configurations. The options allow architects and contractors to meet tough project timelines, while delivering enhanced thermal performance and lower overall operating costs for building owners. The sturdy design makes it ideal for commercial applications, mid- to high-rise projects and more. Its unitized construction accelerates installation while minimizing disruption to the surrounding area or existing tenants, making it an exceptional choice for new or retrofit applications, particularly in urban areas.

Kawneer’s 2500 UT unit-wall system is a sleek glass unitized curtain wall with ultra-thermal performance. It’s designed with a continuous polyamide thermal break vertically and horizontally, providing ultra-thermal performance levels in a cost effective unitized curtain wall system. The one-piece polyamide thermal break eliminates pressure plates and fasteners, reducing the amount of metal used and time required to assemble the system. The framing system is cost-effective and reduces the time to fabricate, assemble, glaze and install. The 2500 also comes with a variety of flexible options – from four-sided captured exterior covers to structural silicone glazed or structural glazing tape configurations. The options allow architects and contractors to meet tough project timelines, while delivering enhanced thermal performance and lower overall operating costs for building owners. The sturdy design makes it ideal for commercial applications, mid- to high-rise projects and more. Its unitized construction accelerates installation while minimizing disruption to the surrounding area or existing tenants, making it an exceptional choice for new or retrofit applications, particularly in urban areas.

Innovative triple pane technology

pdsig.com

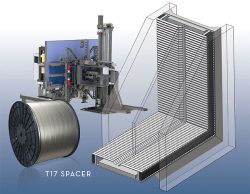

PDS IG Equipment’s new T17 spacer is a flexible, thin, stainless-steel unit. The spacer gives insulating-glass fabricators a simple and cost-effective alternative to producing traditional triple-pane insulating glass units. The T17 offers the performance of a traditional triple pane unit with only a single spacer. It’s designed with thin centre-lite glass and only two edge seals, versus the traditional four-edge seal triple pane design. The T17 decreases gas and moisture movement across the primary sealant, giving glaziers a more durable, thinner, and cost-effective alternative to triple panes. PDS combines the T17 spacer technology with its fully automated IG fabrication system for highly efficient triple pane production. The unique, fully automated spacer application technology requires no added labour compared to traditional dual pane operation. The PDS IG system also includes online vacuum argon filling (with optional krypton) and IG secondary sealing capability.

PDS IG Equipment’s new T17 spacer is a flexible, thin, stainless-steel unit. The spacer gives insulating-glass fabricators a simple and cost-effective alternative to producing traditional triple-pane insulating glass units. The T17 offers the performance of a traditional triple pane unit with only a single spacer. It’s designed with thin centre-lite glass and only two edge seals, versus the traditional four-edge seal triple pane design. The T17 decreases gas and moisture movement across the primary sealant, giving glaziers a more durable, thinner, and cost-effective alternative to triple panes. PDS combines the T17 spacer technology with its fully automated IG fabrication system for highly efficient triple pane production. The unique, fully automated spacer application technology requires no added labour compared to traditional dual pane operation. The PDS IG system also includes online vacuum argon filling (with optional krypton) and IG secondary sealing capability.

Faster system processing

vitroglazings.com

The Intercept LiteLock from Vitro Architectural Glass is a new extruder tip and sealant bead application system with enhanced efficiency, performance and quality improvements. Vitro teamed up with GED to create this new system. It facilitates 30 to 50 percent faster processing speeds on GED’s Intercept oven and roll press while creating a wider manufacturing process window. The Intercept LiteLock nozzle tip applies sealant in a unique bead geometry, which gives a robust adhesion to the spacer metal substrate at near-finished bond line width. The system has been tested on standard double glazed insulated glass units and triple glazed IGUs across multiple over and roll press speeds and temperature to give effective processing recommendations and robust glass and spacer adhesion. The Intercept spacer system is constructed in a U-channel design with tin-plated steel or stainless steel rather than traditional box shaped metal or foam.

The Intercept LiteLock from Vitro Architectural Glass is a new extruder tip and sealant bead application system with enhanced efficiency, performance and quality improvements. Vitro teamed up with GED to create this new system. It facilitates 30 to 50 percent faster processing speeds on GED’s Intercept oven and roll press while creating a wider manufacturing process window. The Intercept LiteLock nozzle tip applies sealant in a unique bead geometry, which gives a robust adhesion to the spacer metal substrate at near-finished bond line width. The system has been tested on standard double glazed insulated glass units and triple glazed IGUs across multiple over and roll press speeds and temperature to give effective processing recommendations and robust glass and spacer adhesion. The Intercept spacer system is constructed in a U-channel design with tin-plated steel or stainless steel rather than traditional box shaped metal or foam.

Fast-cure sealant

dow.com

Dowsil 121 structural glazing sealant is a fast-curing, two-part, neutral-cure, RTV silicone sealant for use in structural and weatherseal applications. It is approved for structural and weatherseal applications with strong mechanical properties. It is odorless and features a non-corrosive cure. Dowsil 121 is designed for excellent stability through wide temperature range: -50 to 150 C. It includes stable viscosity for the base and catalyst with no heating required. The cured product exhibits excellent weathering characteristics and a high resistance to ultraviolet radiation, ozone, heat and humidity. Rated for primerless adhesion to alodine and anodized aluminum. Delivers adhesion to Dowsil structural sealants for reglazing applications. Adhesion and structural strength is achieved in 24 to 48 hours. Dowsil 121 meets ASTM C719 Class 25 (G,A,O) and ASTM C1184 structural sealant specification. Structural glazing applications reviewed by the Dow technical staff may qualify for a project-specific adhesive warranty. Certain sealing materials used in the anodizing process may increase the potential need for primer to gain adhesion within a 24-hour period. Dowsil Primer-C OS is recommended for fast and consistent adhesion, especially to Kynar, polyester powder coat and other high-performance substrates approved for architectural structural glazing applications. Dowsil 121 is suitable for repair and/or replacement of structurally glazed glass and other substrates where a fast cure is required, such as on-site structural glazing, including storefront systems, and attachment of panel stiffeners. Also useful for in-shop structural glazing where the use of a two-part pump is not viable and assembly, installation or repair of structurally glazed glass and other substrates.

Dowsil 121 structural glazing sealant is a fast-curing, two-part, neutral-cure, RTV silicone sealant for use in structural and weatherseal applications. It is approved for structural and weatherseal applications with strong mechanical properties. It is odorless and features a non-corrosive cure. Dowsil 121 is designed for excellent stability through wide temperature range: -50 to 150 C. It includes stable viscosity for the base and catalyst with no heating required. The cured product exhibits excellent weathering characteristics and a high resistance to ultraviolet radiation, ozone, heat and humidity. Rated for primerless adhesion to alodine and anodized aluminum. Delivers adhesion to Dowsil structural sealants for reglazing applications. Adhesion and structural strength is achieved in 24 to 48 hours. Dowsil 121 meets ASTM C719 Class 25 (G,A,O) and ASTM C1184 structural sealant specification. Structural glazing applications reviewed by the Dow technical staff may qualify for a project-specific adhesive warranty. Certain sealing materials used in the anodizing process may increase the potential need for primer to gain adhesion within a 24-hour period. Dowsil Primer-C OS is recommended for fast and consistent adhesion, especially to Kynar, polyester powder coat and other high-performance substrates approved for architectural structural glazing applications. Dowsil 121 is suitable for repair and/or replacement of structurally glazed glass and other substrates where a fast cure is required, such as on-site structural glazing, including storefront systems, and attachment of panel stiffeners. Also useful for in-shop structural glazing where the use of a two-part pump is not viable and assembly, installation or repair of structurally glazed glass and other substrates.

A precise curve

sedak.com

Sedak recently extended its production capacity in the field of curved glass. The company’s new 18-metre bending furnace allows you to create large-format functional glazing. The furnace is designed for series production of cylindrically curved, fully tempered glass and thermally toughened glass in large formats of up to 3.6-by-18 meters. The bending and tempering takes place in a single production process. Sedak’s new technology ensures a fast and precise adjustment in bending radius, so that glass for projects with multiple geometries can quickly be produced. Depending on the width, glass can be curved to a minimum radius of 1,000 millimeters. Sedak offers the complete spectrum of curved glass in almost any form. The glass panes are produced in a suitable process depending on the glass geometry. Sedak also offers lamination bending for glass of up to 20 meters and the gravity bending process for almost any architectural free-form. The curved glass is further processed to safety glass and insulation glass and, just as for flat glass, this can be put through the complete Sedak processing spectrum from gold printing to bullet-resistant glass.

Sedak recently extended its production capacity in the field of curved glass. The company’s new 18-metre bending furnace allows you to create large-format functional glazing. The furnace is designed for series production of cylindrically curved, fully tempered glass and thermally toughened glass in large formats of up to 3.6-by-18 meters. The bending and tempering takes place in a single production process. Sedak’s new technology ensures a fast and precise adjustment in bending radius, so that glass for projects with multiple geometries can quickly be produced. Depending on the width, glass can be curved to a minimum radius of 1,000 millimeters. Sedak offers the complete spectrum of curved glass in almost any form. The glass panes are produced in a suitable process depending on the glass geometry. Sedak also offers lamination bending for glass of up to 20 meters and the gravity bending process for almost any architectural free-form. The curved glass is further processed to safety glass and insulation glass and, just as for flat glass, this can be put through the complete Sedak processing spectrum from gold printing to bullet-resistant glass.

Print this page

Leave a Reply