Oldcastle Glass now offers architects and designers the ability to have

any image they can imagine printed on glass in full colour with i-Glass

decorative glass. Imagine famous works of art or graphic imagery, even

replicate the look of real wood or marble printed so realistically on

glass you will have to look twice.

Changes the face of decorative glass

Oldcastle Glass now offers architects and designers the ability to have any image they can imagine printed on glass in full colour with i-Glass decorative glass. Imagine famous works of art or graphic imagery, even replicate the look of real wood or marble printed so realistically on glass you will have to look twice.

Unlike previous production methods which employed screen printing that required high production costs, time-consuming processes, and rather limited design possibilities, i-Glass prints digital images directly on heat-treated, monolithic, laminated and insulating glass that look just like the original. Oldcastle Glass says its i-Glass offers the ability to print complex designs and multiple colours to achieve truly unique results.

www.oldcastleglass.com

|

|

Clear rim for satin etched glass

Acheruntia Glass in Acerenza, Italy, says its OpalPlated satin etched glass product is earning its place in decorative glass applications.

With production capacity and market demand for traditional rolled patterned glass on the decline, the company says decorative satin etched patterned glass is gaining momentum because design possibilities are endless and custom made patterns can be made available in relatively small production runs.

The company runs two entirely different production facilities. One plant produces a very exclusive etch for high end architectural applications. The second plant is where OpalPlated is made, a modern facility for volume production of regular plain satin etched glass. Continuous in house design modifications greatly increased productivity of this plant with quality procedures built in and documented at each step of the production.

The company says the quality of OpalPlated glass is due to the careful selection of the base float, low iron, and mirror; only recently produced glass from few selected floats enters the line. The etching process is automated and takes place in a closed environment where all parameters are controlled.

OpalPlated is different from many other etched products by the absence of a clear rim as 100 per cent of the surface is etched and has perfectly clean edges. Its soft surface finish is uniform and consistent – even between different production runs.

OpalPlated comes in clear and tinted float, low iron, mirror and can be imported in Canada through ASE Europe.

www.acheruntiaglass.com

|

|

Endless opportunities

Meltdown Glass has introduced its newest texture called Horizons (with base texture MD-101 Stone). With hardly any size or length limitations, the possibilities for this texture are endless. The company says any of its standard 100-200 series textures can be used as the base texture, which gives customers many choices and variations to this new glass texture.

www.meltdownglass.com

Colour on both sides

Bendheim has introduced nine new Spring/Summer colour additions to its standard palette of Colour-Coated glasses, now also available in safety laminated form. These rich colours are featured in either fire-polished or Satintech etched glass surface options. The new palette includes deep fuchsia, bright orange, signal red, royal and light blues, lime and hunter greens.

Bendheim’s colour-coated glass production utilizes isocyanate-free paints which minimize VOC emissions. The end result is an environmentally-friendly and safe product with stable, durable UV resistant coatings formulated and applied to last for years. Colours can be fused to practically any type of glass for exterior cladding, or for interior applications such as feature walls.

Bendheim now provides its colour-coated glasses in safety laminated form. Lamination protects the coloured surface from scratching during handling and installation. It also ensures the safety of building occupants and can create totally different design aesthetics on both sides of the glass.

For example, one side of the laminated glass may be a glossy hunter green, the other side a light blue Satintech etched glass. Lamination makes colour-coated glasses ideal for use in partitions and stair railings.

www.bendheim.com

Solar collecting

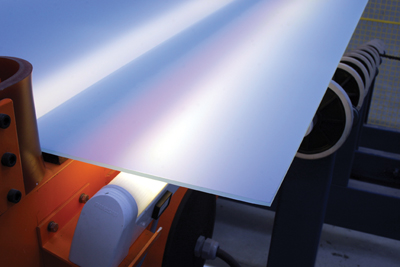

PPG Industries has introduced Solarphire AR (anti-reflective) glass, a new product engineered to maximize solar energy transmission to solar-collecting photovoltaic cells.

Solarphire AR glass is formulated with a proprietary anti-reflective coating that facilitates the efficient conversion of solar light into energy. In 3.2-millimeter thicknesses, Solarphire AR glass yields a solar-weighted transmittance of more than 93 per cent, making it one of the industry’s most transmissive glass products.

The company says that Solarphire AR glass continues its history of innovation in the development of stacked, thin-film coatings for glass. In 1983, PPG commercialized the world’s first coated low-emissivity (low-e) glass. Over the past quarter-century, the company has continued to advance thin-film coating technology, culminating most recently in the debut of Solarban 70XL glass, the architectural industry’s first magnetron sputter vacuum deposition (MSVD), triple-silver-coated, low-e glass. The company’s thin-film coating capability is now being directed toward the production of solar energy.

www.ppgsolarphire.com

Print this page

Leave a Reply