Features

Community

Event reports

Garibaldi opens its doors

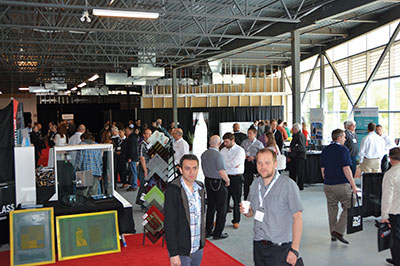

Visitors to Glass Day discover what makes Garibaldi special.

June 4, 2014 By Paul Dixon

On a sunny April 25, Garibaldi Glass hosted the fourth annual Glass Day

at its state-of-the-art fabrication plant in Burnaby, B.C.

On a sunny April 25, Garibaldi Glass hosted the fourth annual Glass Day at its state-of-the-art fabrication plant in Burnaby, B.C. Glass Canada spoke with the three Mobius brothers, Carey, Chris and Craig, during Glass Day, as hundreds of professionals from all facets of the building and design world took advantage of the seminars and table top trade show, or just networked with industry insiders in a relaxed and informal setting. With the opportunity to show off their shop to clients, suppliers and competitors, we asked the Mobius brothers how the business has changed in the three short years since they moved in. Carey, as CEO, says “It’s the design of glass and the complexity of the equipment required. Chris is heavily involved in engineering new processes. We’re having to make custom equipment. The requirements for performance to meet codes now is such that two years ago we never heard of putting double low-E on a unit and now it’s common. We’re seeing more triple glazing in office towers. Triple glazing with a frit and low-E coating into the frit surface within that sealed unit, so the amount of layers or processes involved in some cases has easily doubled. The amount of choices in high performance glass that’s available now is getting crazy.” Chris Mobius concurs, “Now, you’ve got vacuum insulated panels inserted into insulated units just to get the insulated value up, so that you can put more glass into a building. The codes are getting tighter, so the specifications are getting much more stringent to meet those codes.”

|

|

| More than just an open house, Garibaldi hosts a tabletop show and educational seminars at its annual Glass Day. The event has become a critical networking opportunity for the B.C. commercial glazing industry.

|

Garibaldi has built its reputation on delivering custom solutions in this increasingly complex environment. As Craig explains, “A lot of our customers come to us for specialty glazing. We’re not primarily a commodity shop, though commodity glass is a good filler. When we do large jobs, they are generally the complex, inside and outside jobs. We’re known for being very innovative, so often people will come to us with an idea that’s never been brought to life before and we take it on. We’ll build our own equipment to do it, if it doesn’t already exist in the marketplace, just to get the work done.” Garibaldi works closely with everyone involved in pre-production and pre-installation to ensure they can deliver the required product on schedule and avoid having a backlog of inventory in their warehouse – or worse, not being able to deliver the product on time.

The culture of innovation and inclusiveness runs right through the company, a point all three brothers attest to. “Everybody contributes to the innovations”, says Carey Mobius. “It’s not just one or two people, it’s company-wide. A lot of times guys come to us with ideas on how to do something and we’re lucky to have that openness of communication.” Chris talks to the value of open communication. “We work hard to maintain a culture where everybody can eat lunch together in one room. Some of the best ideas come from talking over lunch, it can be as simple as sales staff talking to production.” As Chris and Craig expand on the “really tight” communications system that encompasses the entire operation, it’s not just communicating on an informal basis. Chris says, “Over a 24-hour period we probably average six leadership huddles at every level of the company. We sequence them in order of how the information comes and then gets distributed out.” Craig adds, “at every shift change we have huddles on the floor with half an hour overlap between [them], so everyone is on the same page. They can communicate properly and hand over completely. We go through all our different metrics. Safety, manufacturing, on-time delivery, defects, absolutely everything so that everyone involved knows that if they made a defect or they made a defect the day before we dig into how did it happen and how do we make sure it doesn’t happen again.” From Chris, the one thing that dominates day-to-day operations, whether front office or in the plant, is focus on the customer, “in the office we focus on the work flow and making sure it’s balanced, while the shop floor might worry more about what kinds of defects they need to extinguish and who’s cross-trained in what area so they can handle the workload for the day.”

Garibaldi Glass began almost 50 years ago as a small, family-run business serving a local market. Today the Garibaldi family of employees has grown to number over 150, bringing innovative technology and production techniques to a market that now stretches across North America and is reaching out to Europe and Asia.

Print this page

Leave a Reply