Features

Business intelligence

Contracting

High-traffic doors demand continuous hinges

demand continuous hinges

October 30, 2008 By Bob Cronk*

Contract glaziers and glass shop owners are often called to repair or

even replace badly worn hinges on high-traffic doors. Building owners

and property managers struggle with the hassle and expense of these

repeated repairs, a continuing source of dissatisfaction, and the bad

impression a poorly functioning door makes with customers.

|

| Stainless steel continuous pin and barrel hinges in a variety of finishes match, contrast or accent your building’s design. |

Contract glaziers and glass shop owners are often called to repair or even replace badly worn hinges on high-traffic doors. Building owners and property managers struggle with the hassle and expense of these repeated repairs, a continuing source of dissatisfaction, and the bad impression a poorly functioning door makes with customers.

Continuous hinges, which use a number of fasteners to attach door to frame from top to bottom, distribute a door’s weight more evenly along the frame and reduce repeated maintenance expense and hassle. They are ideal for high-traffic doors in retail storefronts, schools, convention centres, sports facilities, airports and public buildings.

Continuous hinges can also salvage expensive doors and frames since the full-length hinge leaves cover up cut-outs, screw holes and door frame damage.

The two continuous hinge designs – geared or pin and barrel – are offered by several manufacturers, including Select Products; Markar/Adams Rite Manufacturing, a subsidiary of Assa-Abloy; and Hagar Companies.

|

|

| Geared continuous hinges offer dura-bility. A Select hinge endured 25 million open/close cycles (equal to 50 years of use) in independent testing, more than most high-traffic entrances will see in a lifetime. |

|

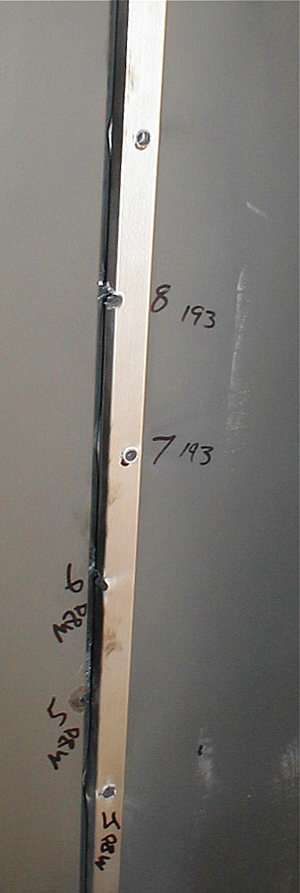

| The U.S. Department of State’s Ballistic Resistance test on a Select geared continuous hinge included 7.62-mm (0.308-calibre), M80, military rifle rounds fired directly at the continuous gear hinge. The hinge passed by withstanding all eight shots. |

Geared continuous hinges

Made of extruded architectural aluminum, geared continuous hinge components mesh together under a cap that runs the length of the hinge. Hinges come in standard lengths from 83 to 120 inches, with custom lengths available.

Several key features give geared hinges an unmatched durability and longevity for high-traffic entrances. Look for pair-matched hinge leaves, manufactured and machined together, that fit doors better and last longer. Also look for lifetime lubrication that helps reduce wear, quiets performance and eliminates periodic maintenance. Anodizing after machining delivers superior wear, durability and corrosion protection.

For architectural appearance, it is possible to match a custom paint

colour on the gear cap or the entire hinge. White hinges are commonly

in stock and custom colour anodizing is available. To meet building fire

codes, these hinges are available with up to a three-hour fire rating.

Geared continuous hinges are initially more expensive, around US$75 to US$100 vs. US$50 for three ball-bearing butt hinges, but their durability make the initial investment pay back easily over the long haul.

Test results

A Select geared continuous hinge has surpassed 25 million open/close cycles in laboratory testing – equivalent to 50 years of average high-traffic entrance use – which is 10 times beyond the Grade 1 cycle count. The ANSI Physical Endurance test, conducted at Architectural Testing, mounted a full-mortise geared continuous hinge on a standard FRP door to simulate a real-world situation. The hinge completed the 25 million cycles with no loss in performance and a measurable drop of only a few ten-thousandths of an inch.

The U.S. Department of State (DOS) approved a. Select geared hinge for use in its embassies overseas to protect workers from mob activities or terrorist attack based on tests conducted at H.P. White Laboratory. In the first test, attackers fired eight shots from high-powered military rifles directly at the hinge from 20 feet away. All bullets were stopped, so the entrance was classified as “no penetration.”

Next, attackers used every means at their disposal including 10 and 12 pound sledgehammers, a 9.0 inch by 2-1⁄2 inch

wood-splitting wedge, 1.0 inch and 3⁄4 inch cold chisels, pry bars, plus other tools to gain entry. After separate attacks lasting one hour, none had penetrated.

As a result, the Select geared hinge earned 60 minute Ballistic Resistance and Forced Entry certification and this model of hinge is now approved for use on all DOS doors.

|

| In the U.S. Department of State’s Forced Entry test, a geared continuous hinge from Select defeated six attackers – using 10 and 12 pound sledge hammers, wedges, chisels, crowbars and more – for 60 minutes. |

Pin and barrel

Pin and barrel continuous hinges use a steel rod that runs the length of the hinge through a series of knuckles. Generally made of stainless steel, they are typically manufactured in lengths from 79 inches to 119 inches, with custom lengths available.

Stainless steel pin and barrel continuous hinges resist corrosion and deterioration, making them a good choice for caustic environments. The stainless steel rod stays flexible and strong in abused openings. Nylon bearings, especially double bearings, create a strong, free moving assembly. Tamper-resistant covers guard against vandalism and reduce the hassle of frequent repairs.

As with geared hinges, pin and barrel hinges are available with up to a three hour fire rating to meet building fire codes. These hinges allow enough flexibility to match, contrast or accent a building’s design with a variety of finishes, including satin on stainless steel and polished, brushed and custom paint on carbon steel hinges.

When selecting hardware, keep in mind that pin and barrel, and geared continuous hinges provide a strong solution to high-traffic entrances. Continuous hinges stand the test of time, while geared hinges stand the test of cycles, sledge hammers, high-powered gunfire and stainless steel pin and barrel resist caustic environments.

*Bob Cronk is vice-president of sales and marketing for Select Products in Portage, Mich.

Print this page

Leave a Reply