Features

Business intelligence

Contracting

From steel to aluminum and back again

... and back again

May 11, 2008 By Jeff Razwick*

In the 1800s, steel revolutionized the way buildings were designed and

constructed. Its strength and ability to be fashioned into various

forms enabled a greater range of construction designs than previously

possible, from long-span bridges to an entirely new type of building

called the skyscraper.

|

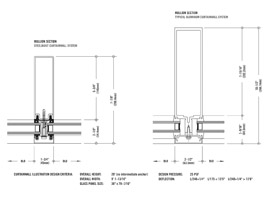

| Steel frames offer narrower face widths and mullion depths than traditional aluminum curtainwall systems, allowing for an easy installation, similar to typical pressure plate systems. |

In the 1800s, steel revolutionized the way buildings were designed and constructed. Its strength and ability to be fashioned into various forms enabled a greater range of construction designs than previously possible, from long-span bridges to an entirely new type of building called the skyscraper.

For the past half century, aluminum has grown in popularity as a building material, especially in glazing where it has become common in many framing systems across North America. Now, the revolution in steel construction is coming full circle as steel framing for glass curtainwalls enables larger spans of glazing, narrower frame profiles, and numerous other design and performance benefits beyond traditional aluminum systems. Glaziers benefit from steel curtainwall systems by having a new option to recommend to architects and designers who are seeking solutions for projects requiring extensive glazing or less framing.

While advanced steel curtainwall systems have been used for years in Europe, they are just now starting to be introduced into North America. European architects and designers often choose steel over aluminum because of its ability to incorporate larger expanses of glass in building designs while minimizing frame dimensions, which is a critical factor for popular day lighting designs.

Steel framing offers a number of technical advantages over traditional aluminum framing. First, is the superior strength of steel, which has a modulus of elasticity three times greater than aluminum. In other words, steel framing members have substantially lower deflection than aluminum, providing greater wind load capacity. As a result, for a given framing profile cross-section, larger spans can be achieved with steel than aluminum and for identical load and deflection requirements, narrower steel frame profiles can be used. In either case, steel allows for larger areas of open glass with less framing with no additional reinforcements required.

For comparison, it is useful to consider the details in a typical two storey span (see Figure 1).

| Figure 1. Curtainwall illustration design criteria. Comparison of a mullion section steel built curtainwall and a mullion section of a typical aluminum curtainwall system. |

|

The steel frames have a face width of only 13⁄4 inches (45mm) versus a typical 21⁄2 inch face width of aluminum. Steel also allows for a narrower frame depth: 53⁄4 inches (146mm) back mullion versus a required depth of nearly eight inches (203mm) for a typical aluminum curtainwall system. Steel curtainwall systems are also available with internal reinforcements to further reduce required frame depths. The minimal frame dimensions allowed by steel are an increasingly desired trait of architects and designers engaged in curtainwall design.

A second advantage of steel is that it has lower thermal expansion than aluminum, which allows for greater design flexibility with fewer or no extension profiles. In addition, steel has a modulus of conductivity (heat transfer) coefficient about one-fourth that of aluminum. The result is a lower chance of heat loss and interior condensation (sweating) on frames.

Steel curtainwall systems also install similar to traditional aluminum assemblies. One system includes a ‘plug and screw’ connection for the framing components, which allows the components to be readily assembled without welding. The result is crisp corner joints with no visible fasteners or weld beads.

|

| Steel framing, supplied by Technical Glass Products (TGP), for glass curtainwalls enables larger spans of glazing, narrower frame profiles, and numerous other design and performance benefits beyond traditional aluminum systems. Photos Courtesy Of Technical Glass Products (TGP). |

In the end, the technical advantages of steel matter when it comes to design options. Steel curtainwall systems enable many captivating glass designs, including large curved or straight walls, atriums and vaulted ceilings, all with slender looking framing. Similar benefits, such as large expanses of uninterrupted glass, are also possible for storefronts and other related applications.

After more than a century of use, steel is indeed back as a revolutionary building material. -end-

*Jeff Razwick is the director of business development for Technical Glass Products (TGP), a Kirkland, Washington based supplier of fire rated glass and framing systems, along with specialty architectural glass products.

Print this page

Leave a Reply