Features

Business intelligence

Contracting

Compatibility of bituminous membranes

membranes. Problems arise when membranes..

May 11, 2008 By David Metzler*

Sealants: Problems arise when membranes come in contact with soft PVC substrates.

Scrupulous detailing of the building envelope to control air and vapour flow, as well as to prevent water penetration into the building, seems to be getting more professional attention now than in years gone by.

The driving forces behind this are numerous. For one, Al Gore and his movie, An Inconvenient Truth, has heightened our social conscience in recent years and governments are responding with incentives to build more energy efficient buildings. In part, this is being achieved using membranes and sealants to control the flow of air and vapour in an effort to minimize the use of heating and air conditioning, and in turn, our impact as a society on the planet. In addition, some parts of the northwestern US and southwestern Canada exhibit rain forest-like climatic conditions which demand specific attention to air and vapour movement as well as waterproofing detail, simply to keep buildings dry and free from rot, corrosion or dangerous moulds.

|

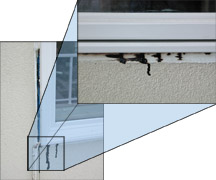

| A ‘peel and stick’ membrane placed in contact with a soft PVC material/gasket. Plasticizers have caused the asphalt in the peel and stick to become liquid and flow out of the system. |

Regardless of our reasons, we continue to use more bituminous based self adhered membranes such as ‘peel and stick’, or liquid applied air and vapour barriers for this purpose. The glass industry is no different from any other. All the detailing behind a curtainwall or glass façade envelope is being done with these same products, liquid or fairly unstable bituminous based ‘peel and stick’ membranes, in contact with many other components of the glazing system, and tied together or overlapped at a weather seal with a sealant of some kind.

The sealants used in the weather seal on a glass building are, more often than not, a high end neutral cure silicone, polyurethane or in some cases even a thermoplastic sealant. Both of these membranes, self adhered and liquid, as well as the various sealants have been tested for compatibility by most of the leading manufacturers of these products. Generally, the neutral cure silicones and low VOC polyurethanes contain little or no solvents. In fact, even the highly solvent thermoplastic sealants are not causing these membranes to breakdown to the point of flow.

Light coloured sealants applied in direct contact with the membranes’ bituminous face will often discolour, even if left to cure in a confined airspace near these membranes. Dow Corning has tested its sealants and concluded that performance is not compromised by this discolouration and for aesthetic purposes, simply substituting for a darker coloured sealant would avoid the discolouration. Based on field experience, the same can be said of any of the higher end silicones or polyurethanes.

More serious problems start to arise when these membranes are brought into contact with soft PVC substrates. Henry/Bakor Company has tested and concluded that the plasticizers in PVC are attracted to the asphalt (bitumen). The plasticizers then render the asphalt very plastic and in some cases to the point of a flowable liquid. It has also been established that higher temperatures will accelerate this reaction. For this softening and flow of the asphalt to occur, there must be physical contact, albeit incidental, of the PVC and bituminous membranes. If the design allows for a separation of the membranes from the PVC gaskets or soft PVC membranes, no plasticizer migration will take place. Otherwise, any contact, however incidental, between these two product groups must be avoided.

Despite the alarming incompatibilities between soft PVC and bituminous membranes, PVC window frames, typically, present less of a problem. This grade of PVC is more rigid and less prone to plasticizer migration within that PVC. However, testing is always recommended to confirm compatibility of bituminous membranes with any PVC substrate!

Since energy efficiency and the control of air flow and protection of buildings from water ingress is so important in the way buildings are constructed today, the likelihood of these liquid or self adhered membranes being eliminated is unlikely.

The solution: If possible, stay away from PVC components and avoid high solvent sealants within the system being assembled. PVC glazing stops, PVC setting blocks and PVC gaskets can easily be substituted for alternative materials in new construction.

If a PVC membrane or PVC gasketed system is already in place, there is always the option to substitute the bituminous air/vapour or waterproofing membrane with a membrane that does not contain asphalt. There are many polyurethane based liquids that can be substituted for bituminous based air and vapour barriers as well as waterproofing membranes. These products are typically not vapour permeable and, as such, cannot be substituted in a vapour permeable air barrier application. The other downside to these liquids is that many of these products still typically rely on a solvent carrier and therefore are not the most environmentally friendly to apply.

As all glass professionals know, options do exist!

Author’s note: This article does not address sealant adhesive compatibility to the self adhered and liquid bituminous membranes. This topic has been examined by all the large sealant and membrane manufacturers. It is well documented and information relating to this issue is available from any of these manufacturers: Tremco, Dow, BASF, Henry/Bakor, Soprema. -end-

*David Metzler is with Cascade Aqua-Tech, a wholesale distributor of specialty products for the construction and manufacturing industry in western Canada specializing in sealants, coatings and waterproofing materials as well as numerous companion products.

Print this page

Leave a Reply