Features

Architectural design

Contracting

Three ways to glaze

Choosing architectural glass is about balancing options.

August 25, 2015 By John Shaw

There’s nothing worse than a blank piece of paper. When designing a building envelope, architects and engineers are confronted with a nearly endless array of options for glass and glazing materials. Our expert recommends looking at each project as an exercise in good/better/best optimization.

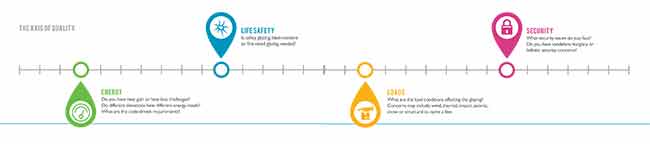

There’s nothing worse than a blank piece of paper. When designing a building envelope, architects and engineers are confronted with a nearly endless array of options for glass and glazing materials. Our expert recommends looking at each project as an exercise in good/better/best optimization. Specifying glass using good, better or best options is a basic concept that can be instrumental in the selection and design process. Various considerations for your glass selections will include safety, energy, loads, and security for a basic system, and can be improved with specialty high performance products to address sound, glare, aesthetics, and performance concerns. These value-added products will differentiate your project to exceed common expectations and would be better/best options.

At a minimum, your glass options must meet minimal energy standards set by the local codes. This baseline standard would be considered a good system. Regardless of the options, the building energy codes drive us to use a prescriptive or component approach to determine what type of glass and quantity should used as defined by the specific application and location. Glass is not a one-size-fits all proposition, and there is no magic checklist, so it is up to the designer to dial in on the project needs and to choose the right glass to specify so there is no room for selection and fabrication errors. According to Bill Cody, architectural design manager for Guardian Glass, some important considerations include the design concept and performance considerations.

Better and best options incorporate various components that enhance the building. There are many considerations, including daylighting, facade design, view and occupancy comfort. All of these factors can play a major role to influence or guide your glass specifications. Better and best options are driven by the architect, glazier, contractor and other decision makers that support the clients’ decisions. Other considerations for selecting the right glass include:

- Sound- Does the glass need to provide specific sound attenuation performance?

- Glare- Will any or all the glazing contribute to excess glare or the need to control interior glare?

- Esthetics- What is the desired reflected colour? How much exterior reflectance is desired? What about interior reflectance? Is complimentary or contrasting spandrel glass needed?

When specifying glass you will want to ask about the availability of the product and the lead time. It is often preferable to choose glass where more than one manufacturer makes similar products, so your contractors can find the best deal in cases where sub-contractors source glass from more than one fabricator.

Another factor entering into your good/better/best calculation will be the maintenance, cleaning, and repair/replacement costs of the product you specify. You need to know how fast you can get replacement glass during construction and post commissioning. Can the glass be cleaned easily? Coatings can add a number of desirable performance features, but coated glass may require special handling or cleaning practices.

Are the sizes and configurations of glazing being drawn actually constructible or practical? Too often, a designers imagination outstrips the actual state of present technology, especially when budgets are involved. The fenestration framing system selected must be able to accept the glass unit configuration. Warranties are important as well and need to fit the project requirements.

Better and best options create the ability to extend past the common use of the minimum standard glass and allows alternative systems to be used in the specifications, as well as enhanced designs and attachment systems. Attachment systems may dictate or influence the appropriate glass selection and minimum standard for glass specification. The design and overall look of the building is determined by the design/architecture. The proper selection of materials and specification will ensure that vision is brought to life. Unfortunately the specifications are only as good as the execution, and follow-up may require verification throughout the design, manufacturing, fabrication and installation process.

The selection of best glass – for instance, specialty enhanced architectural glass – will allow some give-and-take to what type of system can be used and may allow the designer to use more glass on the project. “All architects want all glass but our energy codes don’t allow it,” says Marc Chavez, associate partner at ZGF. “I would like a cost effective vacuum insulated glass that is 1/4 as thick as a standard triple pane system: an enhanced system that would not limit our glass usage because of U-value. Having said that we do need to manage the heat gain.”

Specialty products can help manage solar heat gain. For example, Raven Windows offers a thermochromic smart window filter that will auto-tint as the building heats with no control systems and or no human interaction. As the building cools it will transition to its clear state. This advanced technology includes a solar-activated filter that is laminated to the #2 glass surface. When paired with double silver low-E the SHGC can reach a impressive 0.104.

Another great example is Retro Solar. This product is designed to maximize daylighting, while managing solar heat gain and glare, as well as direct light streaming into the building. This advanced technology uses stationary louvers encased within the glass IG unit to reduce solar heat gain while providing an esthically pleasing, clean design with easy maintenance while eliminating the need for cumbersome and unsightly shades or blinds. It is designed to redirect the overheating sun back into the sky and reflects glare-free illumination in the depth of the room with no control systems or electricity.

Your glass selections can be tailored to fit your integrated design objective and outcome. Integrated design allows all the aspects of the building to be considered. Various sides of the building will use various specifications. North- and east-facing sides will vary drastically and may use good or better glass, while south- and west-facing sides of the building may use better or best glass. Balance the matrix of design concerns such as architectural design, interior design, heating, ventilation and HVAC systems as well as cost effectiveness and occupant comfort. As the energy and performance expectation grow, the selection options in terms of glass choices and systems decreases. While the advancement of the systems and glass specifications are mainly driven from our minimal energy standards, “the design side is having to learn the engineering of the system used because it is a constraint on the design, while the systems used are becoming an engineered commodity,” Chavez says.

Balancing short and long term costs will help guide your selections. As part of this process it can be helpful to quantify the requirements such as U-factor, SHGC, visual light transmittance, sound transmission, reflectance, and relative heat gain. To accurately determine short- and long-term costs you will need to involve the glass manufacturer, glass fabricator, window manufacturer and glazing sub-contractor. Balancing the short- and long-term costs will invariably result in a small window of options. Cost may seem to be an overwhelming consideration, but when balanced against long-term costs they are not so prohibitive.

Whether you’re specifying good, better or best, you can avoid some challenging pitfalls by providing clear and detailed specifications. For example, quality pitfalls can be minimized by specification. A recent example includes the Seattle Stadium Place. This project exemplifies the style of Seattle with an amazing design and incredible look, but the ripple effect reflected on the glass distracts from the overall design concept. This is the result of the use of less expensive, imported low iron glass (that very well may have fit the spec) but failed to achieve the overall intent for the look of the project. A more detailed specification such as requiring a tighter roll wave, bow, and warp specification could have reduced the opportunity for distortion or substitution.

When specifying glass it is important to consider application, performance, appearance, costs and design concept. Specifying glass using good, better or best options can be instrumental in the selection and design process. The availability and use of new and exciting products like architecturally driven high performance glass are value added products that will differentiate your project to exceed common expectations.

John Shaw, principal of Shaw Designer Resources (SDR), has been working with the architectural and design community for over eight years, specializing in the Pacific Northwest. SDR brings marketing expertise with a focus to educate while creating interests and specifications by building relationships for partners. Feel free to contact SDR directly at John@ShawDesignerResouces.com or visit the website at shawdesignerresources.com.

Print this page

Leave a Reply