In the early part of 2011 during an ASTM task group meeting, the

chairman of the Glass Strength Committee asked that a small contingent

put together background and history along with information on the use of

the ASTM E 1300 Standard Practice for Determining Load Resistance of

Glass in Buildings.

In the early part of 2011 during an ASTM task group meeting, the chairman of the Glass Strength Committee asked that a small contingent put together background and history along with information on the use of the ASTM E 1300 Standard Practice for Determining Load Resistance of Glass in Buildings. Jeff Haberer of Cardinal IG and I offered to pursue the task. The following information in this article is part of the effort that was put into the writing of a paper used to explain the request. It is hoped the explanation relating to the background and evolution of this standard will give the reader insight into how the group has promulgated a standard that has been in place now well over 22 years. The standard continues to be updated and added to in an effort to assist the glass industry, architects, engineers, contractors, designers, consultants, researchers and others interested in glass use for buildings.

|

|

| Standards for lateral load give guidance to architects and structural engineers as they try to do new things with glass. As technology makes new designs possible, standards must keep up in order to ensure the new technologies are used safely. Above, the Sony Centre in Berlin, Germany.

|

Currently this standard is used throughout the United States and parts of Canada for determining uniform lateral load resistance (i.e., snow and wind load) of glass used in buildings. It is referenced by the model building codes in the U.S., Canada and other countries. Origins of the standard will be discussed along with historical and recent updates. The standard offers a practical approach to lateral loading that addresses many, if not most, of the glazing types offered today, including, monolithic, annealed, fully tempered (toughened), heat-strengthened, laminated (with shear modulus equal to or greater than PVB), insulating glass (double and triple glazed), asymmetric glass constructions, various support conditions (one-, two-, and three-side support), and combinations of the above.

We will be discussing the progress made in the standard in providing the user with advancements in load resistance of glass based on the development of additional charts for non-factored loads, glass thicknesses, glass type factors, load sharing and increased load magnitudes that have been important to meet glass industry needs.

Architects, engineers, glass fabricators, glazing contractors and others have obvious needs to know and understand the strength of glass. Wind load, snow load and self weight are the primary concerns when it comes to glass for use in buildings. In these times of ever-expanding designs, there is also a need to evaluate such special applications as point loads, line loads, partial loading, impact loading and other designs beyond the typical vertical window or sloped glazing with four-side structural support to the glass. Throughout the long history of using glass in buildings, users have increased the thickness of the glass in order to meet the resistance of lateral forces that would tend to break it. The need has always been for a practical and convenient way to evaluate just when to increase the thickness for added strength to meet design load requirements.

ASTM E 1300 is a practice that lays out a methodology for evaluating glass load resistance and allows the user to determine if a glass type and construction has adequate strength to be in compliance with the architectural design requirements or achieves code compliance.

Glass strength evaluation prior to ASTM E 1300

Prior to the introduction of the ASTM E 1300 standard there were other methods used in the United States to evaluate glass strength for buildings. In the 1960s and into the 1980s most architects and engineers used one simple chart that described the assumed strength of each glass thickness. These charts expressed maximum load capability versus glass area with a line for each thickness of glass based on a probability of breakage of eight lites per 1,000 for annealed glass. As new types of glass saw increased use, adjustment factors were established to address the strength for heat-strengthened, fully tempered, laminated, insulating, and certain pattern glasses. The straight-line chart (see Figure 1) was adopted by many building code agencies for evaluation of glass strength for glass used in buildings.

These charts were based on empirical results from testing to failure of thousands of various-sized plates of annealed glass for each thickness. There were at least 25 lites tested to destruction using aspect ratios of 1:1 to 1:5 for all the glass thicknesses tested. Testing of over 3,000 lites of monolithic factory-fresh glass helped to develop these initial glass strength values at LOF Research Facility in Ohio. The information was commonly used for selecting glass subjected to uniform load conditions for 60-second durations with a design factor of 2.5 and firm four-edge support, and was eventually incorporated into many model building codes.

In the 1970s, efforts were made by glass manufacturers to improve their understanding of glass strength and better predict the statistical nature of glass. Most notable among these was work by PPG Industries. This work employed a maximum stress approach coupled with finite element analysis that considered plate geometry and not just total plate area (PPG 1979). From this work, a series of glass thickness charts were created. These were likely an improvement over the earlier straight-line charts, but they did yield somewhat different results. Because of this, the charts were deemed controversial and did not attain uniform acceptance by code bodies and practising architects/engineers.

|

|

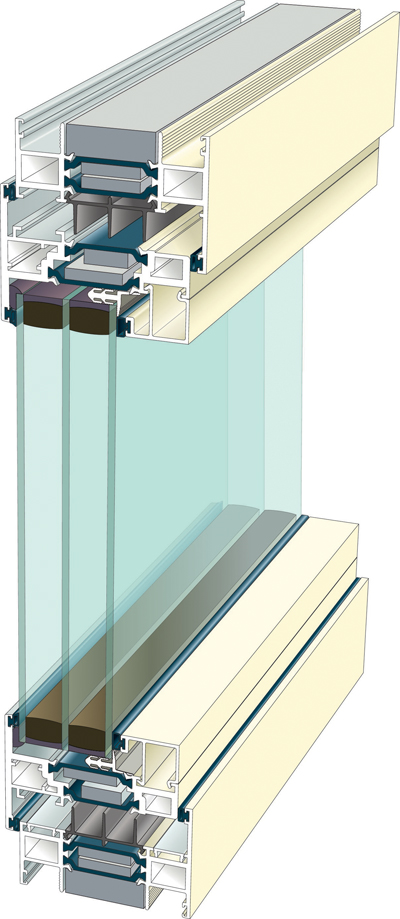

| Early versions of ASTM E 1300 never envisioned this level of complexity in window design. (Photo courtesy of Traco)

|

Around the same time, W. Lynn Beason produced a study introducing a glass failure prediction model. This became the basis for initial discussions within ASTM on glass strength for buildings. This work is well documented elsewhere (“A Failure Prediction Model For Glass,” 1980; “Basis for ASTM E 1300 Annealed Glass Thickness Selection Charts,” 1998). A brief account is presented here. The theory addresses reasoning for the high coefficient of variation in glass strength. This variation is the result of the orientation and density of surface flaws in the glass.

The theory employs the work of Weibul (1939) who offered a statistical failure analysis for predicting the strength of brittle materials. Using this analysis, the glass failure prediction model uses two parameters called “m” and “k,” which relate to the surface flaw conditions. These two parameters are used in a risk function equation employing plate dimensions, elasticity of the glass, load duration, distribution of stress in the plate, and magnitude of applied load. This very complicated function was then synthesized into a series of charts for each glass thickness. The charts have plate width and height on separate axes.

Moving the glass strength controversy to ASTM

As we have discussed, ASTM E 1300 was born out of controversy in the industry when new approaches to glass strength yielded different results from the conventional straight-line charts of the 1960s and 1970s. Being a consensus organization, ASTM (now ASTM International) was perhaps uniquely suited to address the controversy. Unlike other standards organizations, ASTM is a not a national standards body. Membership and participation is open to anyone anywhere in the world. Membership is initiated by the participants’ own requests, not by appointment or invitation. Committees are balanced, so no more than 50 per cent of the participants are producers. The remainder must be consumers or general interest. The latter includes consultants, architects and academics.

With this organizational structure, the task was set to come to a consensus agreement on what to use for glass strength. Initial work took nearly 10 years of exhausting debate and discussion until a final draft document was produced. The previously noted glass failure prediction model was agreed to be the basis for the new standard. Compromises were made on the values for the surface flaw parameters m and k. These were chosen to accurately reflect the strength of weathered glass removed from buildings and resolve the controversy in the industry. Values for the parameters are given in the standard. The committee felt the use of weathered glass represented a more practical effort to describe the basis for the evaluation of load resistance for glass used in buildings.

Early revisions and updates

The first version of the standard, ASTM E 1300-89, was released in 1989. This version only covered annealed monolithic glass of rectangular shape with support on all four edges and with a lateral load duration of 60 seconds. Twelve U.S. glass thickness designations were covered from 2.5-millimetre to 22-millimetre. A chart for each thickness was provided. Optional procedures for centre deflection and estimating probability of failure were included in an appendix. An example of the non-factored load chart for six-millimetre glass is shown in Figure 3. This is similar to what was presented in the original 1989 ASTM E 1300 standard.

It was clear that more than monolithic annealed glass was used by the industry. After a period of general acceptance to the approach within the E 1300 document, strategies for handling different glass types were addressed. In 1994, a second version was issued that offered type factors for annealed, heat-strengthened, fully tempered, laminated, and two-pane insulating glass containing lites of the same type. In addition to factors for the glass types with 60-second load duration, the revision also included type factors with 30-day load duration. This was for evaluation of a typical snow load.

For the 1997 version of the standard, the ASTM task group began to address other needs. These included evaluation of insulating glass units that are asymmetric. This refers to having mixed glass types and thicknesses on each lite of glass in the insulating glass unit. An example would be an exterior six-millimetre tempered lite, with a roomside lite of 13-millimetre, annealed, laminated glass. This type of construction is especially common in sloped glazing, but there had never been any standardized way of evaluating its strength.

This asymmetric analysis entails far more complexity than the symmetric case. Hence, a major restructuring of the strength adjustment factors had to be executed. In the asymmetric IG example cited above, the thicker lite will take more of the load than the thinner lite. An approach to determining each lite’s share of the load was needed. Additionally, the differences in glass type (fully tempered versus annealed laminated) requires examination of each lite individually according to its type and to the determined share of the applied load.

To accomplish all this, an assumption was first made that load sharing is proportional to the stiffness of the lites. This is estimated by taking the ratio of the cube of the thicknesses. A table of load share factors was created that laid out all possible combinations of glass thicknesses for short-term (60-second) loads. A second table of load share factors was created for IG constructions with laminated glass under long-term loading (30 days). Since laminated glass has a different stiffness behaviour under long-term loading, this second table assigned load share for each individual glass ply in the laminated layup.

The addition of the asymmetric IG analysis was a major step forward. While based on assumptions that were not perfect, results were judged to still be conservative within the realm of the stated breakage potential of less than eight in 1,000. The advantage was that more common IG constructions could be evaluated using a standardized consensus practice.

As far as standards and testing have come over the last decades, there are still many potential improvements under discussion. Watch these pages in the coming months for more updates from the ASTM task group.

Bill Lingnell has over 46 years of experience in the technical field of glass and architectural products. He has held such senior management level positions as vice-president of engineering and technical services at a wall systems company, corporate vice-president of a building envelope contractor, and director of new products and technical services for a major glass manufacturer. He holds three master of science degrees in engineering (civil, mechanical and engineering science) from the University of Toledo and a bachelor of science in civil engineering from Ohio University. Lingnell is a registered professional engineer in five states. As a member of various professional groups, code bodies, trade organizations and industry associations, he has contributed to the writing of standards and guidelines for test procedures pertaining to the use and testing of glass, wall systems, sealants and wall components through ASTM committees E-6, F-12 and C-24.

Print this page

Leave a Reply