April 18, 2024

The Engineer: Why glass is invisibleApril 11, 2024

That’s Rich: Bring on AI

March 19, 2024

TOP GLASS TEN SNEAK PEEK

March 14, 2024

Flannery guests on Better Buildings for Humans

October 26, 2023

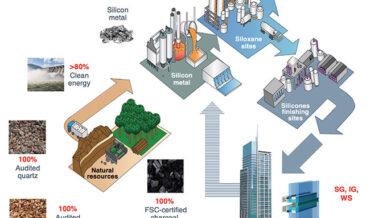

Licence to innovate

October 26, 2023

Whole carbon

April 18, 2024

Non-residential permits jump 12.3% in February: StatsCanApril 15, 2024

Haring moves on from NGAApril 11, 2024

Vitro announces partnership with the Pittsburgh SteelersMarch 26, 2024

New glass search tool from VitroMarch 19, 2024

Guardian and Velux team up on VIG developmentMarch 14, 2024

Antamex goes into receivershipMarch 14, 2024

ASHRAE conference to offer a big perspectiveMarch 7, 2024

OCS predicting strong activity in 2024February 28, 2024

FGIA hears about free embodied carbon calculatorFebruary 28, 2024

Muessig named president of AzonFebruary 22, 2024

Shellard joins Fenestration Canada board

Advertisement

Stories continue below

-

Apr

30

2024Top Glass

Mississauga, Ont. -

Jun

03

2024FGIA Summer Conference

Montreal -

Sep

16

2024FGIA Fall Conference

Minneapolis, Min. -

Nov

06

2024FenBC Regional Technical Summit

Surrey, BC

Popular Topics

Architectural design Association news Business intelligence Codes and standards Community Contracting Energy efficiency Energy Manager Envelope Event reports Fabrication Films, coatings & laminate Glass Hardware & glazing systems Innovations Insulating Glass Machinery Podcasts Processing & productivity Software Under the Glass Webinars Women in Construction Women in Manufacturing